Autoclave with glass vacuum structure

A vacuum and autoclave technology, applied in the field of autoclave with glass vacuum structure, can solve the problems of easy generation of bubbles and glass bubbles, etc., and achieve the effect of effective steaming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

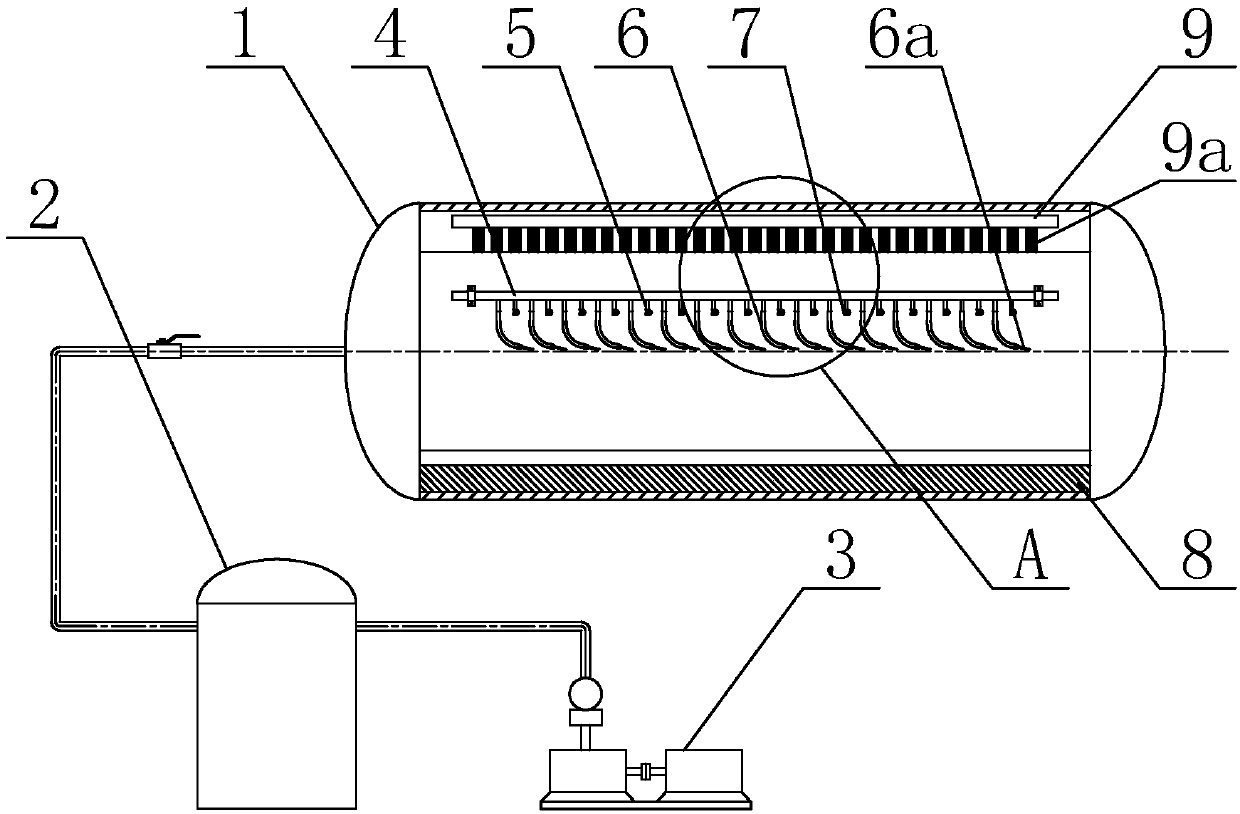

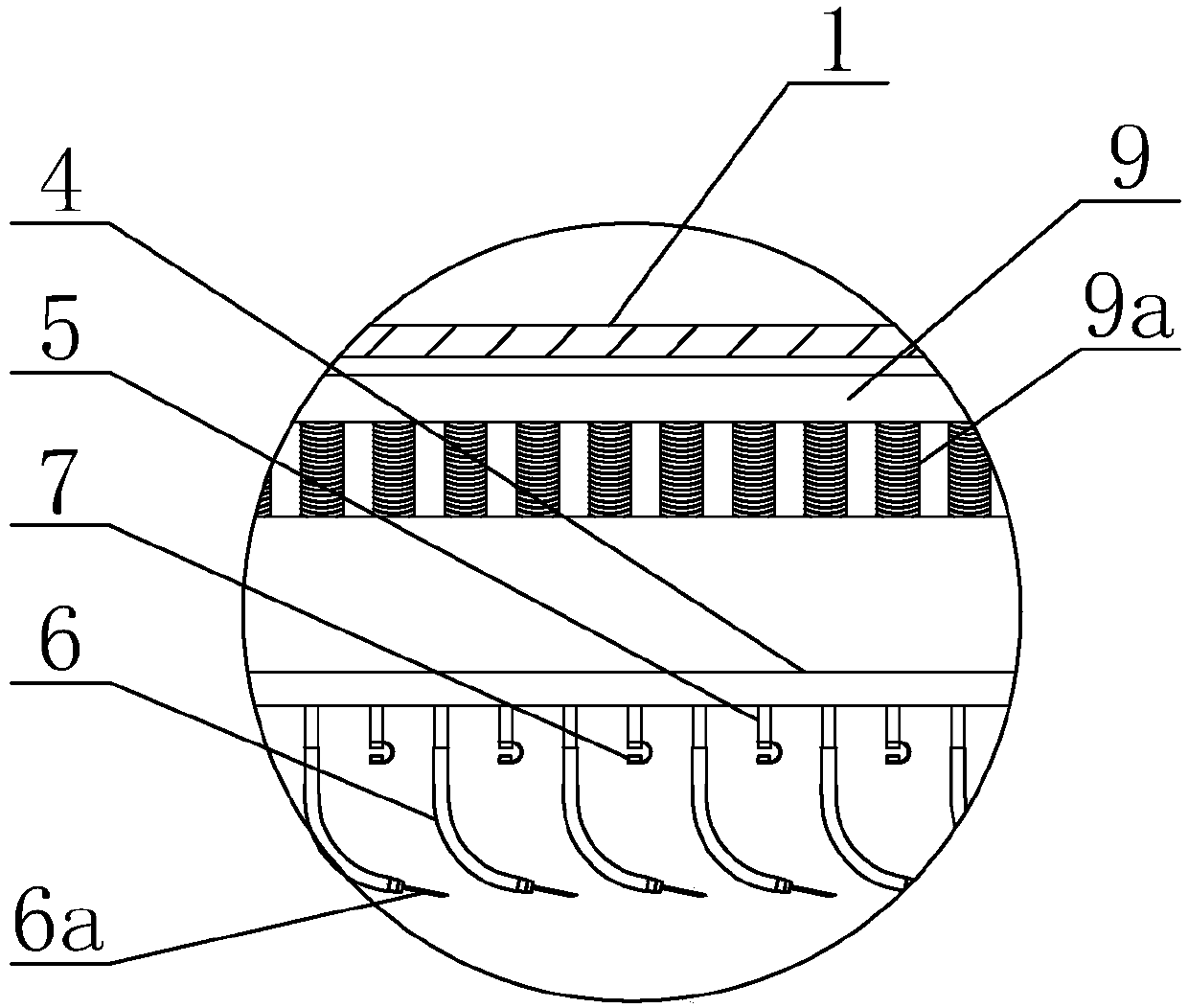

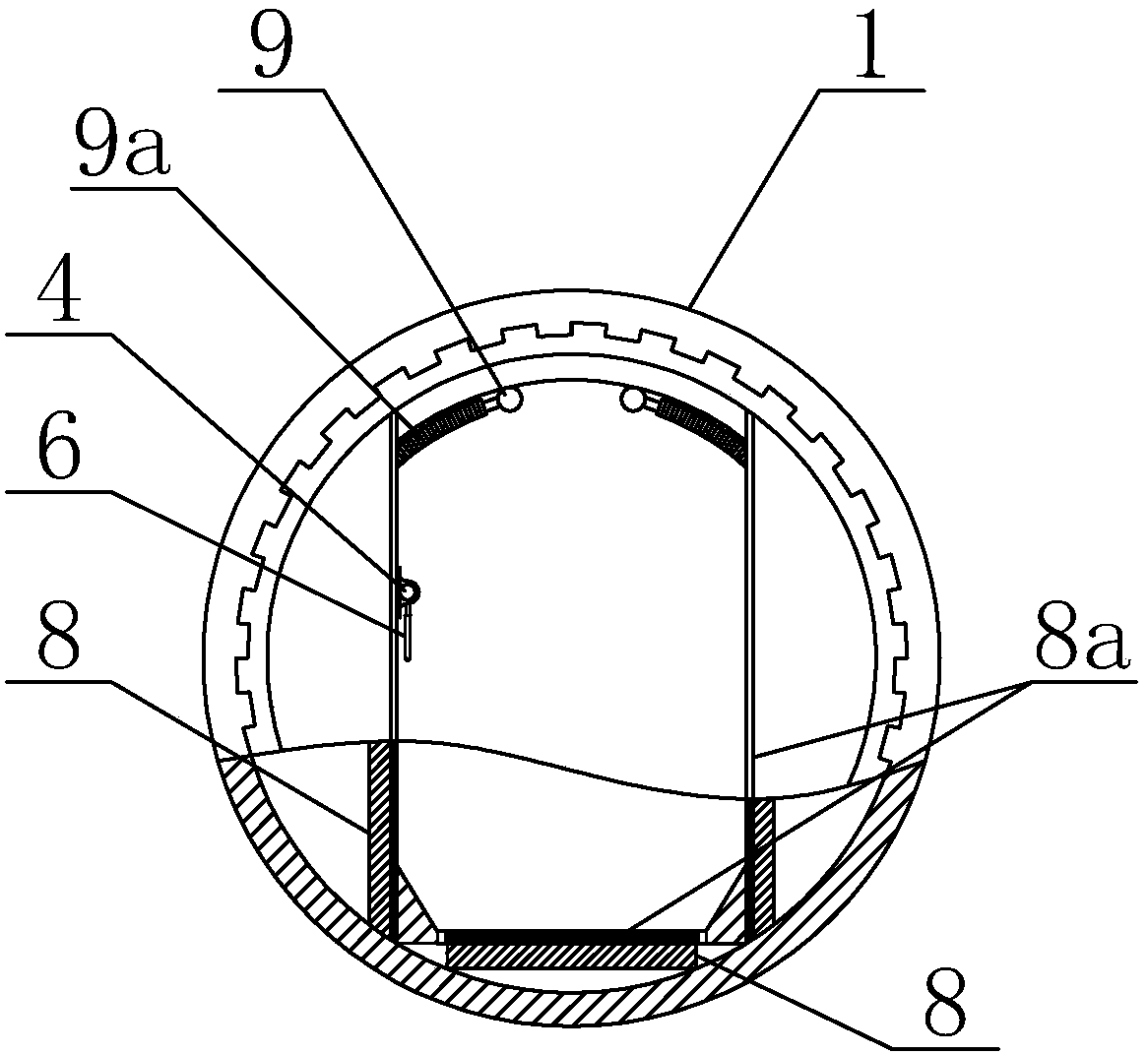

[0018] Such as figure 1 and 2 Shown in and 3: a kind of autoclave with glass evacuation structure, is made up of still body 1, gas storage tank 2 and vacuum pump 3 that are communicated by pipeline successively, the inner wall of described still body 1 is provided with vacuum tube 4, so The vacuum tube 4 communicates with the gas storage tank 2, the vacuum tube 4 is a hard straight tube, the vacuum tube 4 is arranged horizontally, and is parallel to the central axis of the kettle body 1, and the vacuum tube 4 is evenly distributed with vacuum branch tubes 5 , the vacuum branch pipes 5 are all perpendicular to the vacuum pipes 4 and arranged vertically downwards in parallel. One of the two adjacent vacuum branch pipes 5 is connected with a hose 6, the other is provided with a sealing plug 7, and the outer end of the hose 6 is provided with a suction needle 6a.

[0019] Such as figure 1 and 3 As shown: the side wall and the bottom of the kettle body 1 are provided with a hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com