Heat sealable printing sheet

A recording sheet, heat-sealing technology, applied in the directions of copying/marking methods, labels, applications, etc., can solve the problems of peeling off the ink-receiving layer and the overall hardening of the recording sheet, and achieve the effect of good bending characteristics and excellent adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

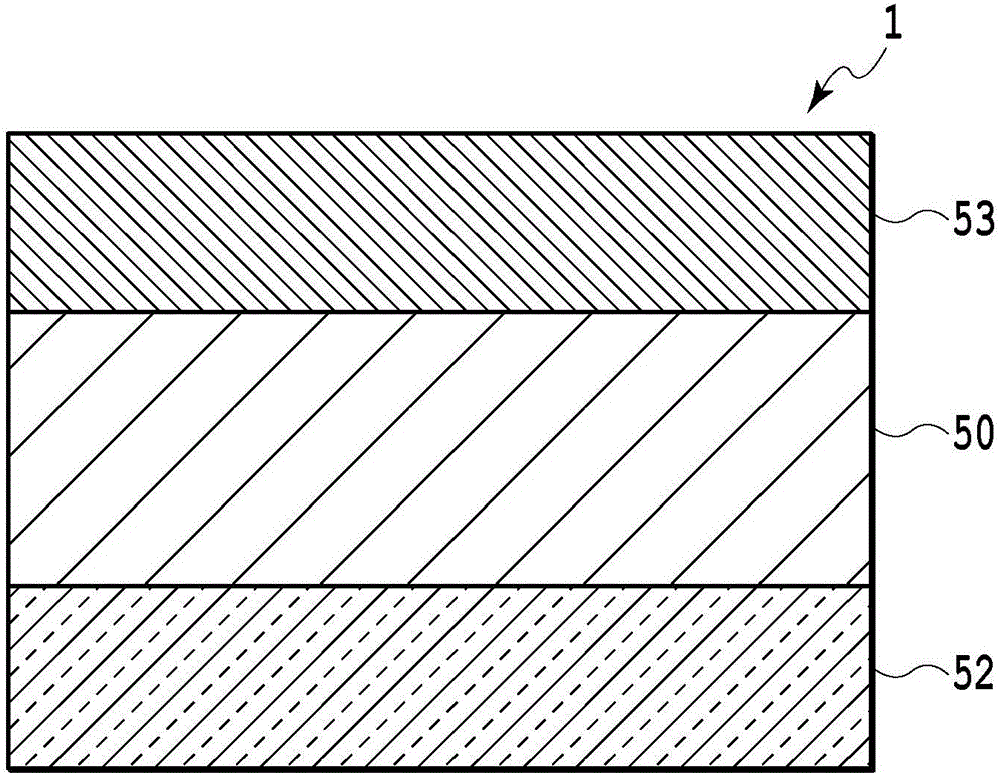

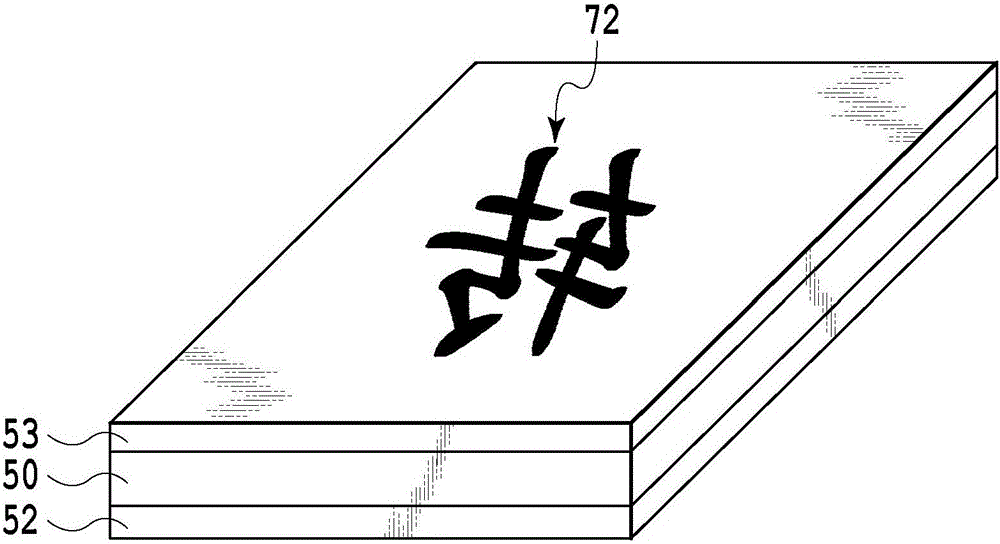

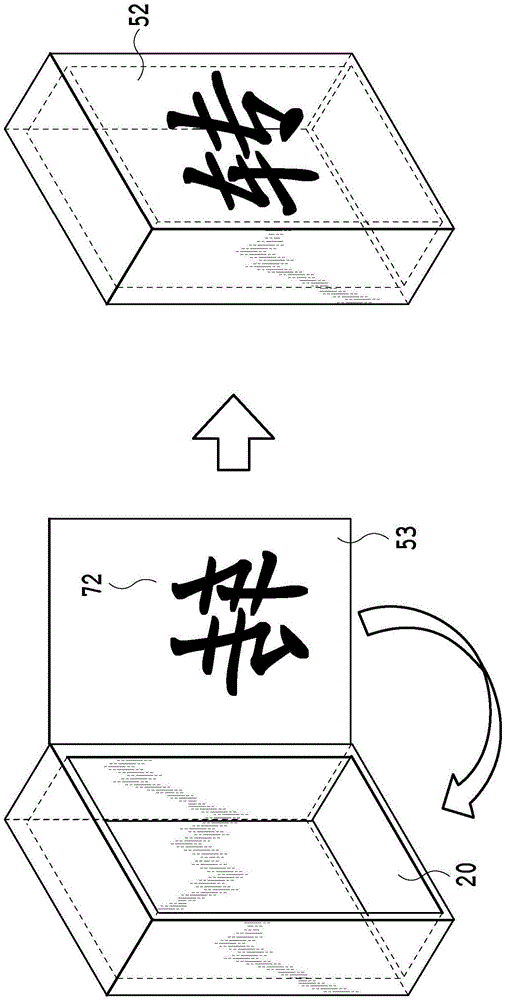

Image

Examples

Embodiment 1

[0335] [Preparation of alumina hydrate dispersion]

[0336] 20 parts of alumina hydrate (trade name "Disperal HP14", manufactured by Sasol) having a boehmite structure (pseudo-boehmite structure) was added to pure water. Further, 0.4 part of acetic acid was added to perform degumming treatment to obtain an alumina hydrate dispersion liquid. The average particle diameter of the alumina hydrate fine particles in the obtained alumina hydrate dispersion liquid was 140 nm. 0.3 part of boric acid was added to the obtained alumina hydrate dispersion to obtain a 20% boric acid-added alumina hydrate dispersion.

[0337] [Preparation of polyvinyl alcohol aqueous solution]

[0338] Polyvinyl alcohol (trade name "PVA235", manufactured by Clara) was dissolved in ion-exchanged water to prepare an aqueous solution of polyvinyl alcohol having a solid content of 8%. In addition, polyvinyl alcohol had a weight-average degree of polymerization of 3,500, a degree of saponification of 87 to 89 ...

Embodiment 2

[0345] Except changing the acrylic resin to Tg-34.0 ℃, the trade name "Binilburan 2642" (manufactured by Nissin Chemical Industry Co., Ltd.) with a solid content concentration of 40.0%, and changing the addition amount to 0.55 parts, the same method as in Example 1 was obtained. Heat-sealed recording sheets and packages.

Embodiment 3

[0347] Except changing the acrylic resin into Tg0 ℃, solid content concentration 30.0% (trade name "Binylburan 2651", manufactured by Nissin Chemical Industry Co., Ltd.) Enclosed documentaries and packaging.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com