Automotive high-voltage wire harness assembly

A high-voltage wire harness and assembly technology, applied in vehicle components, circuits or fluid pipelines, transportation and packaging, etc., can solve the problems of thin soft wires such as hair, automobile influence, etc., to prevent electromagnetic interference, improve EMC performance, structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

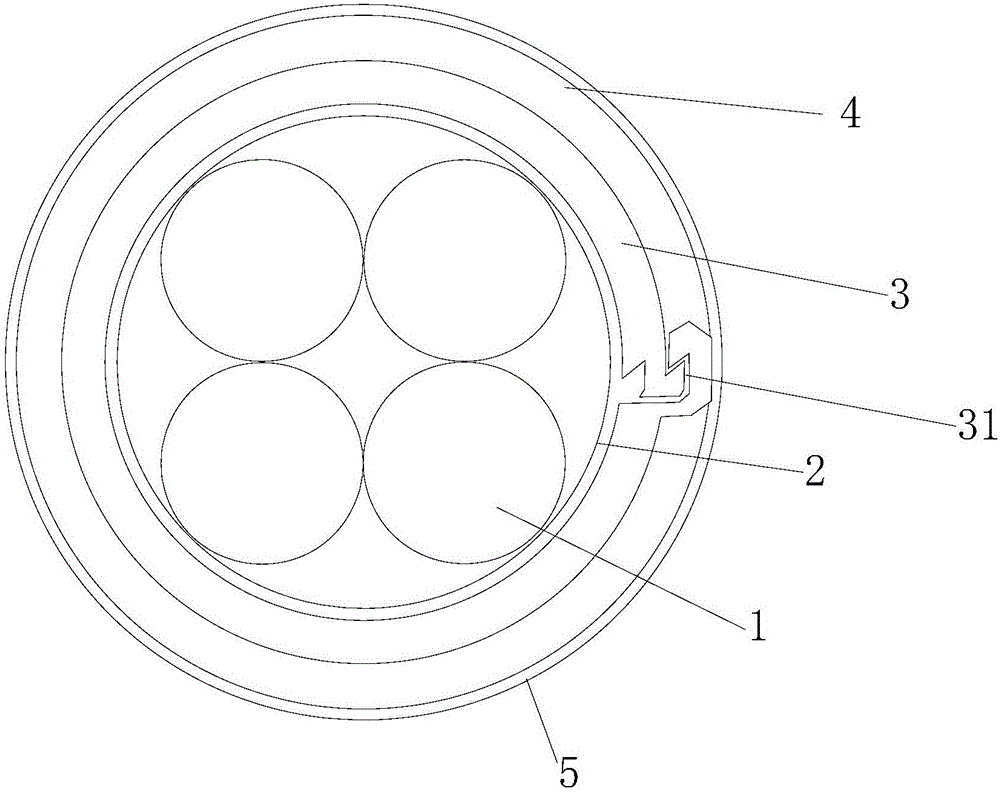

[0012] Below in conjunction with accompanying drawing, the present invention is described in detail:

[0013] Such as figure 1 As shown, an automobile high-voltage wire harness assembly of the present invention includes a four-ring rubber tube 1 integrally pressed and formed, and each round tube of the four-ring rubber tube contains electric wires. The shape of the longitudinal section of the four-ring rubber tube is Four tangent circles, each with a diameter matching the diameter of the wire. The four-ring rubber tube is covered with a copper strip 2, and the copper strip 2 is covered with a sheath 3. The two side ends of the sheath are provided with protruding hooks. The two ends of the sheath are connected by hooks 31. The longitudinal section of the sheath is circular. The sheath is made of flexible elastic insulating material. The sheath 3 is sprayed with a silver-copper conductive paint coating 4, and the silver-copper conductive paint coating 4 is covered with a rubb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com