Rotary base at the end of escalator and its processing method

A technology of a rotary base and a processing method, which is applied to escalators, spray booths, and pretreatment surfaces, etc., can solve the problems of increased labor intensity and difficulty, poor effect, and low load bearing capacity, and achieve fast painting and drying operations, Good heat transfer effect, good contact and bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

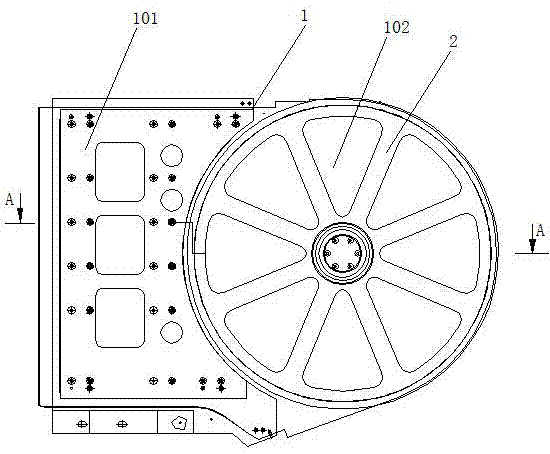

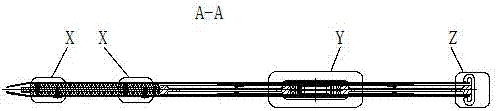

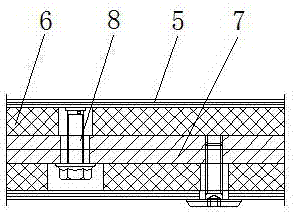

[0039] Embodiment: refer to attached Figure 1-7 As shown, the slewing base at the end of the escalator includes a base body 1, and the base body 1 includes a connecting part 101, a rotating groove 102 and a fixed support part 103, and the rotating groove 102 is arranged at the front end of the connecting part 101. , the fixed support part 103 is divided into a support left wing 1031 and a support right wing. The support left wing 1031 and the support right wing have the same structure. It is symmetrically arranged in the rotating groove 102 with the supporting right wing, and the gap between the supporting left wing 1031 and the supporting right wing forms a rotary cavity, and the rotary hand wheel 2 is movably connected in the rotary cavity.

[0040] In the present invention, the support left wing 1031 and the support right wing are both circular structures, and a circular guide seat 3 is provided at the center of the support left wing 1031 and the support right wing. The ci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com