Beam crane with top-arranged angular trolley

A technology of beam crane and angle trolley, which is applied in the directions of safety device, traveling mechanism, load hanging element, etc., can solve the problems of easy falling of electric hoist, low lifting height, difficult positioning of lifting load, etc., to achieve high performance. Superior, eliminating shaking, easy to use, install and maintain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with drawings and embodiments.

[0030] The invention is designed according to relevant national standards such as GB / T3811-2008 "Code for Design of Cranes" and GB6067-2010 "Safety Regulations for Hoisting Machinery".

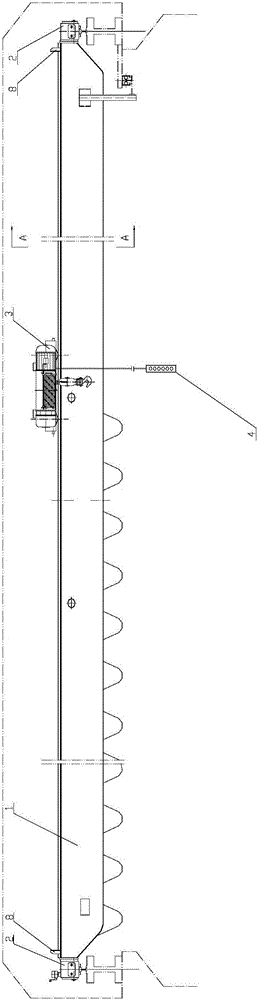

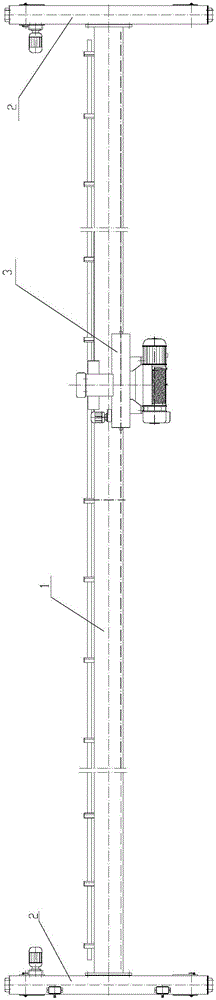

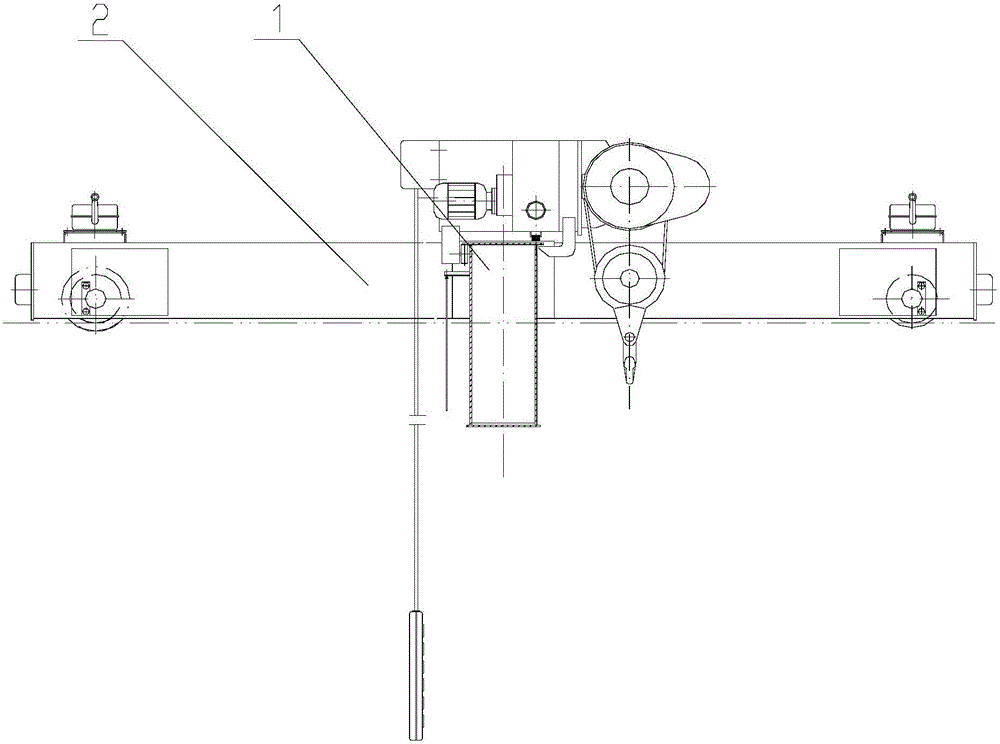

[0031] Such as Figure 1 ~ Figure 3 As shown, the girder crane embodied in the present invention mainly includes main girder 1, end girder 2, corner trolley 3 and electrical equipment 4, main girder 1 and end girder 2 are box girders, and main girder 1 two ends are welded with Connection plate 5, such as Figure 4 As shown, the connecting plate 5 is fixedly connected to the end beam 2 with high-strength bolts 16 , so that the main beam 1 is fixedly connected to the end beam 2 through the connecting plate 5 and the high-strength bolts 16 .

[0032] Such as Figure 4 As shown, the main girder 1 includes a main girder upper cover plate 6, a main girder main web 20, a main girder sub-web...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com