Preparation method for improving pamabrom refining yield and purity

A technology of yield of pamabromide and bromine, applied in the field of medicine, can solve problems such as poor uniformity, unfavorable drying, etc., and achieve the effects of reducing the amount of solvent, being beneficial to later drying, and loosening the crystal form

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

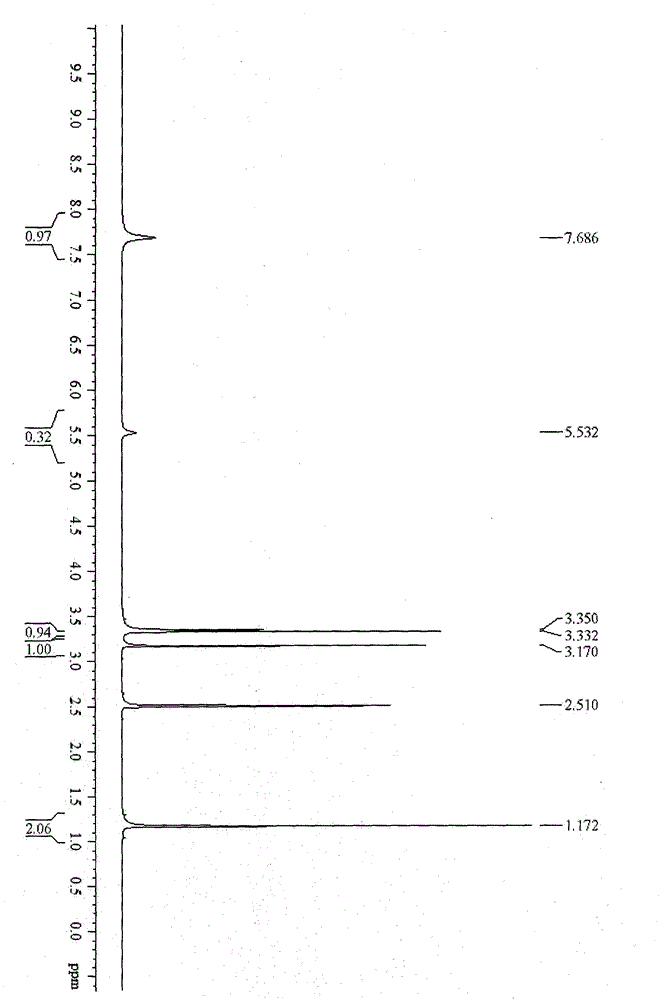

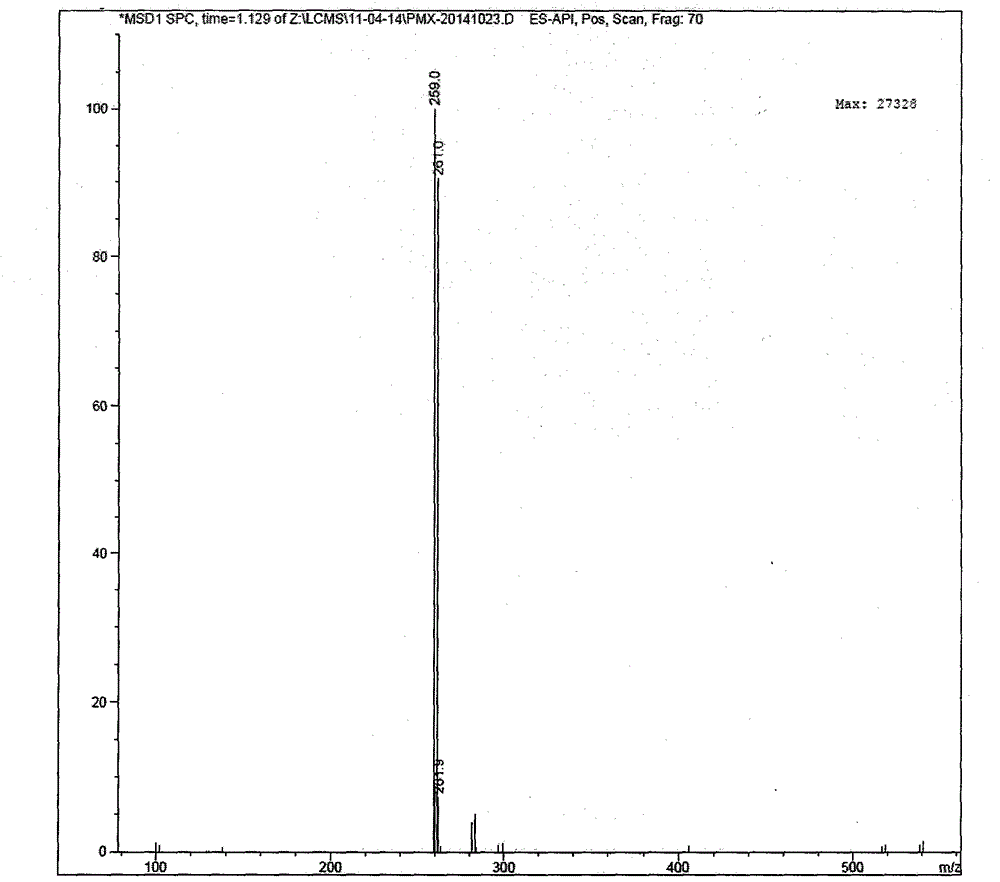

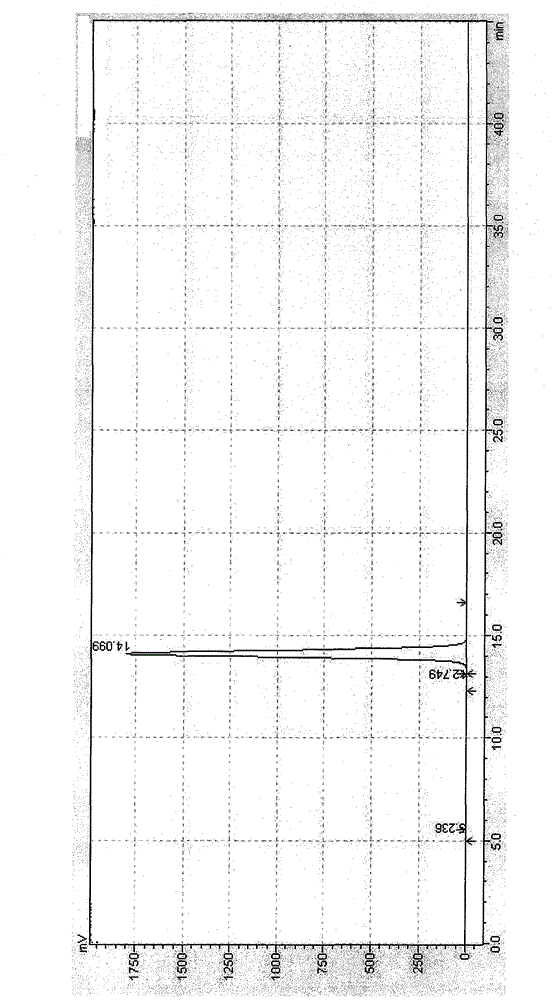

Image

Examples

Embodiment 1

[0023] According to the refining method of Pamabromide described in Chinese patent CN200910172351:

[0024] Take 140g of crude product Pamabromide, put it into a 1000mL three-necked flask, add 240g of ethanol and 40g of the mixture, stir to dissolve, heat up to 50°C, add activated carbon, continue to stir for 20min, filter while it is hot, stand for crystallization, filter, 30g without Washed with water and ethanol, and dried under vacuum to obtain 43.5 g of the product, with a yield of 31.1%.

Embodiment 2

[0026] A kind of preparation method that improves the yield and purity of Pamabromide refining provided by the invention 1

[0027] Take 200g of crude product Pamabromide, add it to a 1000mL three-neck flask, add 10g of water, 300g of ethanol, heat up to 55°C, stir to make it completely dissolved, continue to stir for 15min, filter while it is hot, and naturally cool the filtrate to 15- Continue to stir and crystallize at 20°C for 3h, then stand still for 12h, filter, wash the filter cake with 50g of absolute ethanol, and vacuum-dry the filter cake to obtain 168.6g of pure Permabromide with a purity of 99.99% and a yield of 84.3%.

Embodiment 3

[0029] A kind of preparation method that improves the refining yield and purity of Pamabromide provided by the invention 2

[0030] Take 800g of crude product Pamabromide, add it to a 5000mL three-necked flask, add 40g of water, 1200g of ethanol, heat up to 55°C, stir to make it completely dissolved, continue to stir for 15min, filter while it is hot, and naturally cool the filtrate to 15- Continue to stir and crystallize at 20°C for 3 hours, then stand for crystallization for 12 hours, filter, wash the filter cake with 50 g of absolute ethanol, and vacuum-dry the filter cake to obtain 676.0 g of pure Permabromide with a purity of 99.99% and a yield of 84.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com