Weaving method for imitated yarn-dyed chinlon down-proof shell fabric

A fabric and anti-velvet technology, applied in the direction of dyeing, textiles and papermaking, textiles, etc., can solve the problems of restricting the development of nylon printing fabrics, long production delivery time, high cost, and achieve smooth, efficient and sufficient dyeing, and the process is simple and clear. High quality cloth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to further explain the technical solutions of the present invention, specific examples are given below to illustrate in detail.

[0023] A kind of weaving method of imitation dyed nylon downproof fabric of the present invention, comprises the following steps:

[0024] (1) prepare warp yarn (this white yarn) and weft yarn (this white yarn), and carry out plain weaving;

[0025] (2) Refining and dyeing, dyeing with acid dyes during dyeing, in the dyeing process, the weft yarn is made of high amino nylon, the amino content reaches 90wt%, and the high amino nylon contains more positively charged amino groups, which is different from acid dyes The pigment cations in the fabric react to form a deep dyeing effect on the weft yarn of the fabric;

[0026] (3) Calendering;

[0027] (4) Use oily AC anti-velvet glue for coating.

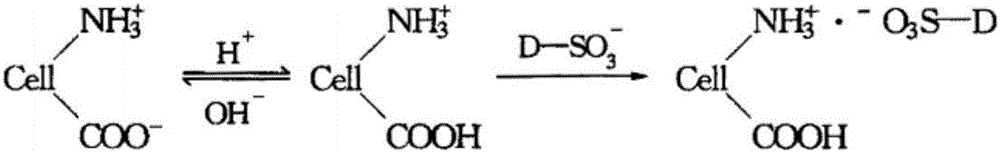

[0028] The process of the present invention is simple and clear, especially when dyeing with acid dyes, the amino and carboxyl groups in nylo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com