Three-dimensional shape detection method for tool wear

A technology for tool wear and detection methods, applied in measuring devices, instruments, optical devices, etc., can solve the problems of difficult to determine optical distortion, difficult calibration, low contrast, etc., and achieve the effect of easy control, concise and clear process, and accurate detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

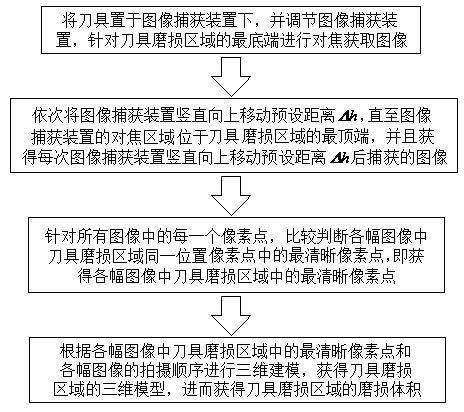

[0033] Such as figure 1 As shown, the present invention designs a kind of tool wear three-dimensional appearance detection method, comprises the following steps:

[0034] Step 001. Place the tool under the image capture device, the image capture direction of the image capture device points to the tool wear area, and adjust the vertical height of the image capture device so that the focus area of the image capture device is located at the bottom of the tool wear area, Obtaining the image captured at this time by an image capture device;

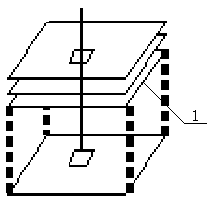

[0035] Step 002. Move the image capture device vertically upwards by a preset distance Δh in sequence until the focus area of the image capture device is located at the top of the tool wear area, and obtain the image captured after each time the image capture device moves vertically...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com