Engineering anti-seismic support

An anti-seismic bearing and engineering technology, used in bridge parts, bridges, protective buildings/shelters, etc., can solve the problem of large size in the height direction of the bearing, achieve excellent bearing capacity, prevent reset, and quickly consume vibration energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

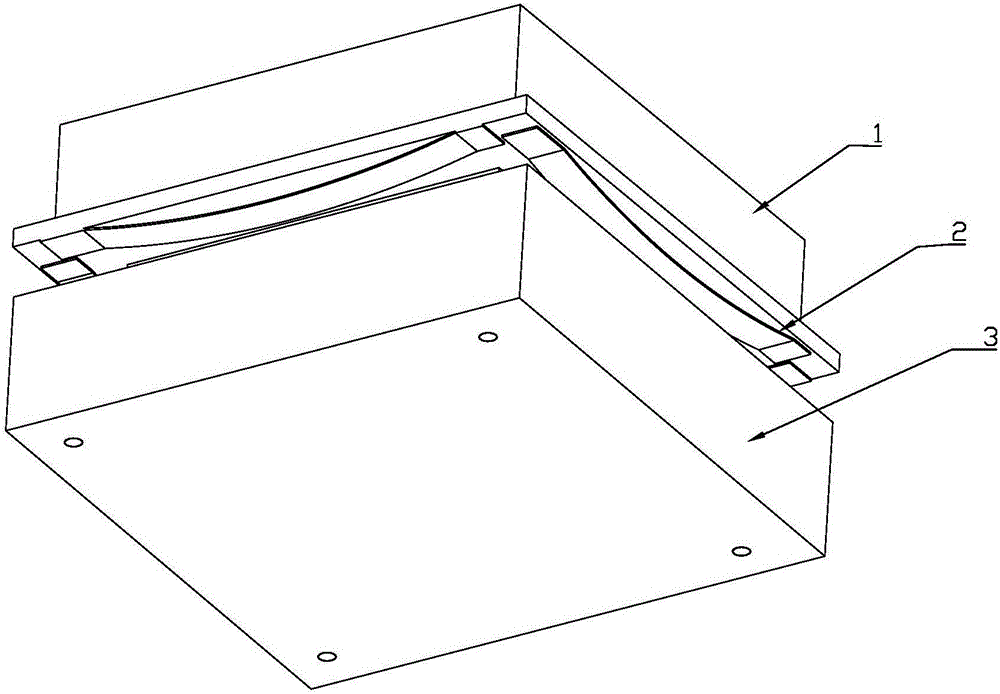

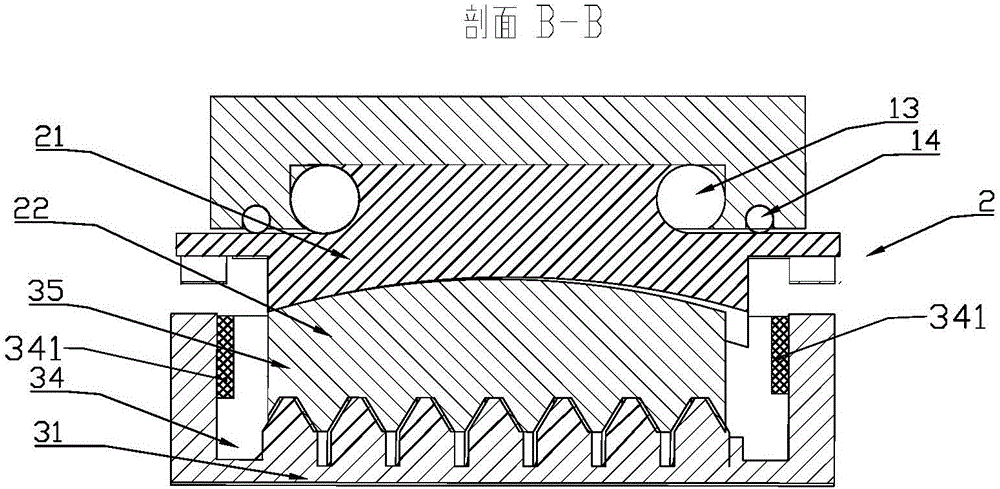

[0048] like Figure 1 to Figure 12 As shown, for existing defects, the subject of protection of the present invention is as follows:

[0049] What is developed is an anti-seismic, self-aligning support, especially an ultra-thin support. Under the same anti-seismic performance, the size of the support in the height direction is compressed by at least half, and the anti-seismic performance is improved.

[0050] Based on the above description, the specific structure of this support is as follows:

[0051] It includes upper, middle and lower parts. The upper part 1 is used to connect with supported objects, such as bridges and beams, and has the ability of elasticity in the vertical direction. The middle part 2 has the ability to consume vibrations and impacts in three dimensions, and has the ability to automatically return to the center of the center. The lower part 3 is used for connecting with supporting beams and columns.

[0052]The upper part 1 is a square block structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com