Unloading steel support node structure and construction method of a stiff cantilever structure

A construction method and steel support technology, which is applied in building structure, building maintenance, construction, etc., can solve problems such as the difficulty of supporting formwork at the bottom of stiff beams, affecting the durability of concrete, corrosion of steel bars and steel beams, etc., and achieve improvement Safety and construction quality, reduce safety hazards, less rusting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

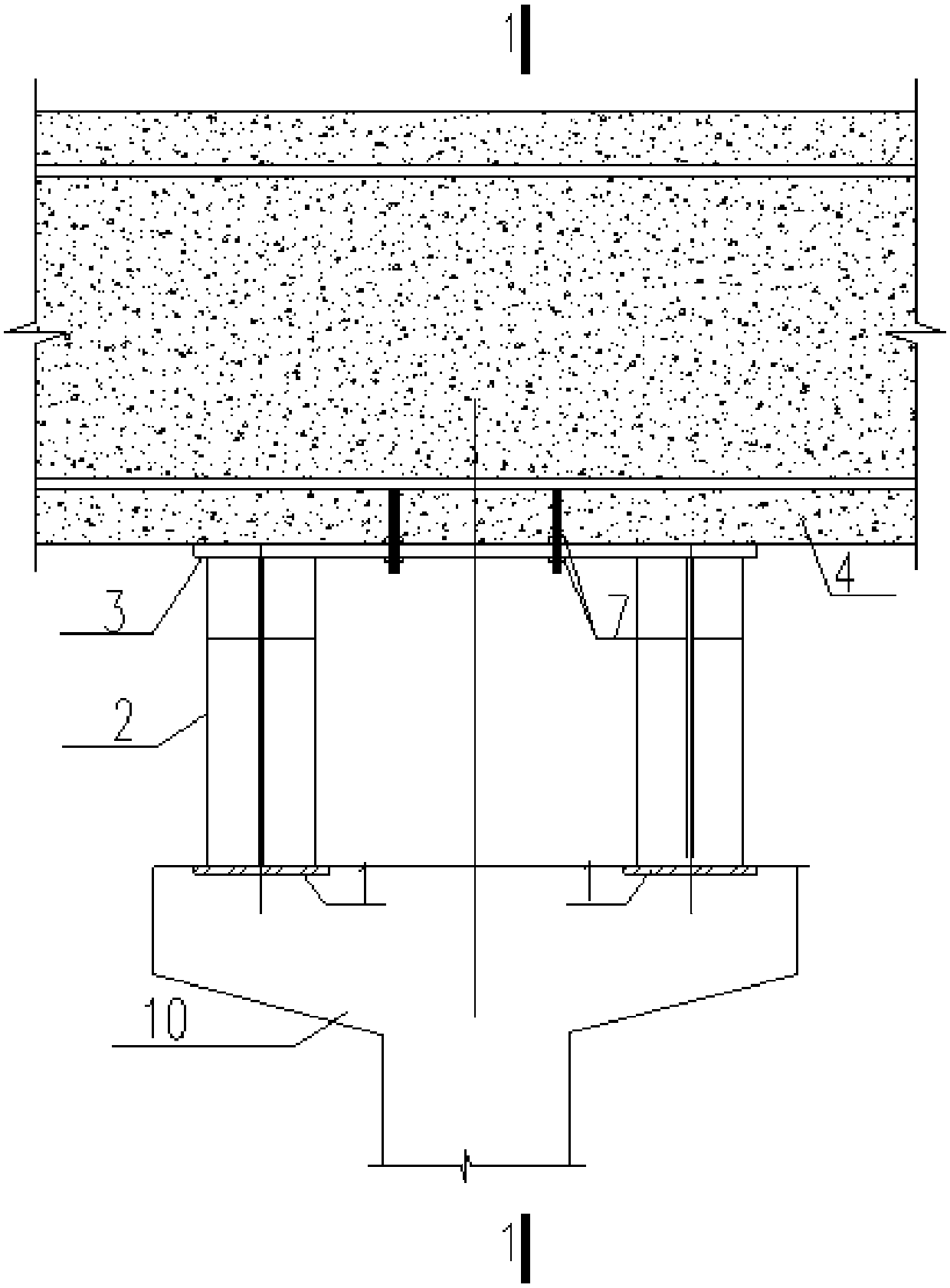

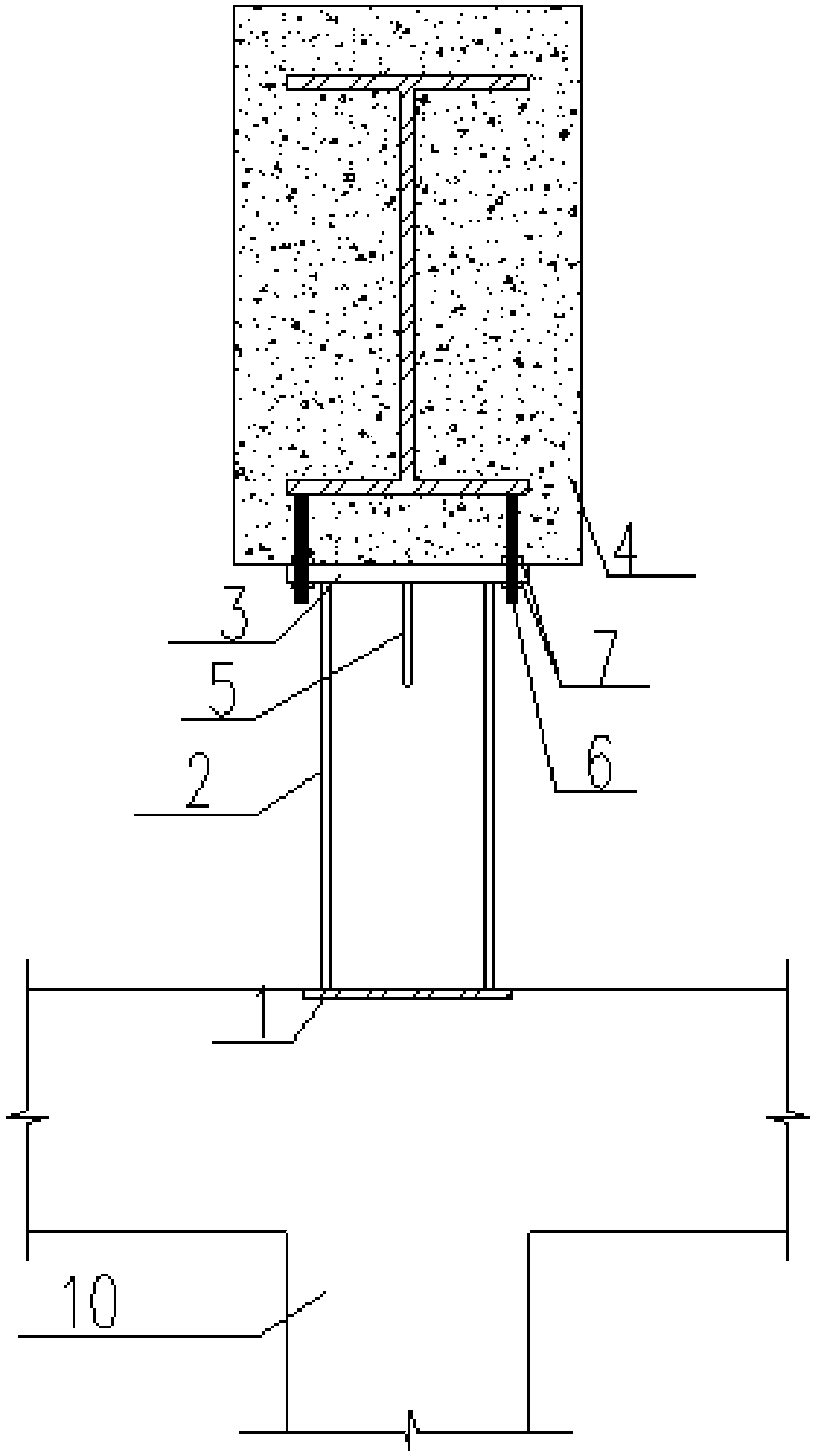

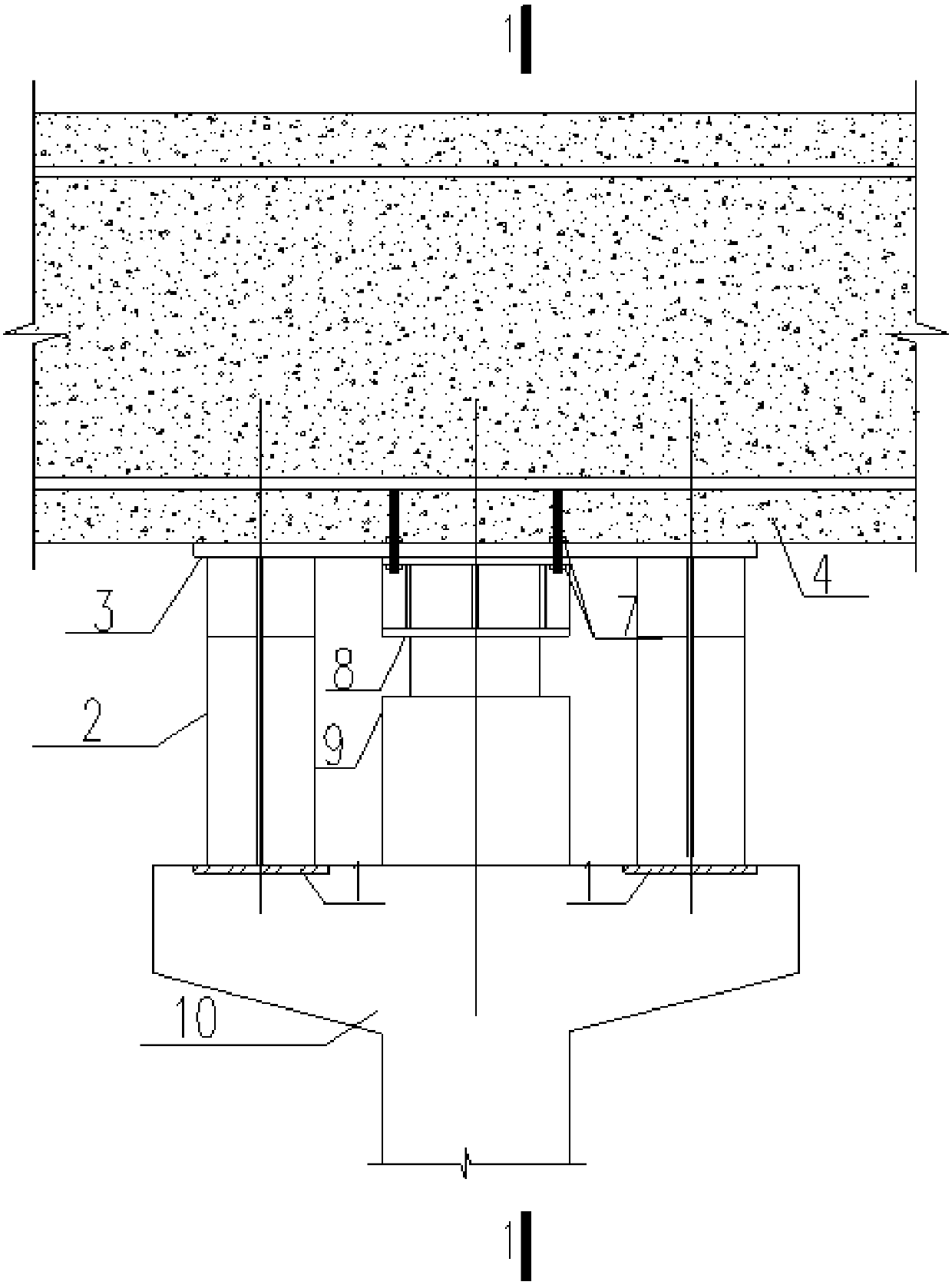

[0027] Such as figure 1 and figure 2 As shown, an unloading steel support node structure of a stiff cantilever structure includes two steel support beams 2 fixed on a concrete structural column or a steel structure support frame 10 and fixed by an embedded part 1. The top of the steel support beam is provided with a supporting steel plate 3, and the bottom of the supporting steel plate 3 is provided with a stiffening plate 5 to improve its supporting strength. The supporting steel plate not only plays the role of sharing the concentrated load of the jack, but also plays the role of supporting the formwork at the bottom. The supporting steel plate 3 is provided with a screw hole for the connecting screw 6 to pass through, and the end of the connecting screw is fixed with a nut 7, that is, an upper nut and a lower nut respectively arranged at the upper end and the lower end of the connecting screw. Specifically, four screw holes are symmetrically opened in the supporting steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com