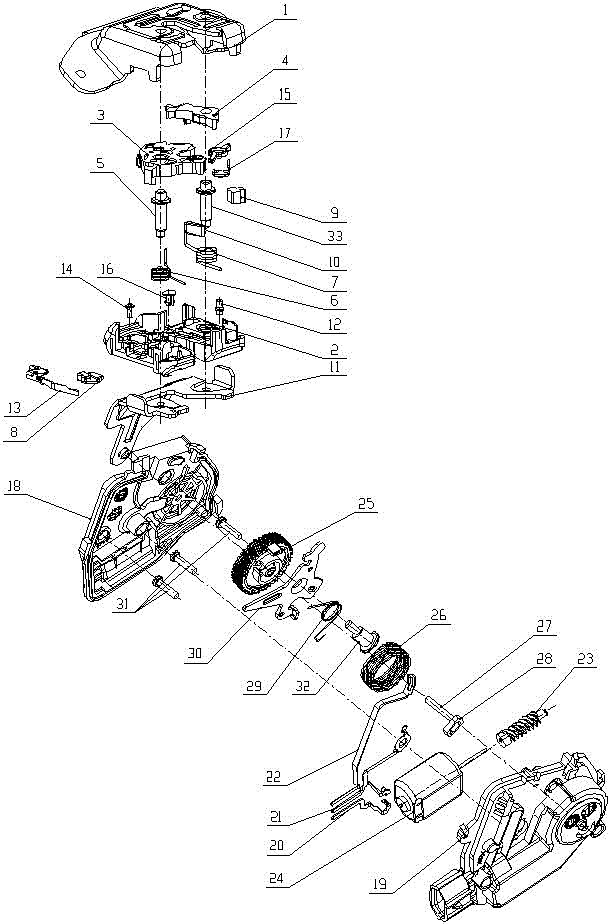

Tail door lock assembly

A tailgate lock and assembly technology, applied in the field of auto parts, can solve problems such as inability to push the car door by itself, potential safety hazards, and poor door closing, achieve good economic and social benefits, eliminate potential safety hazards, and have a compact structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Combine below Attached picture The present invention is further described, but not as a limitation of the present invention:

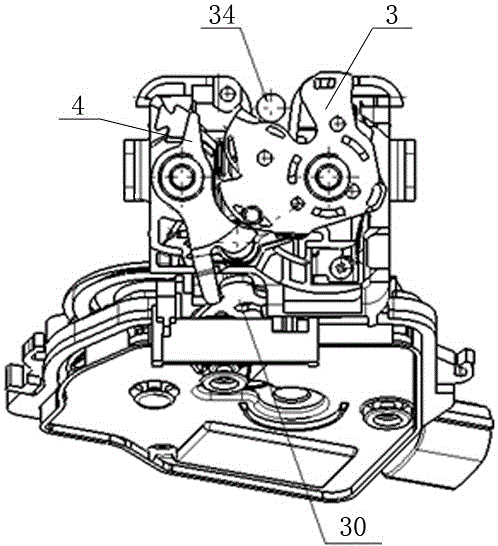

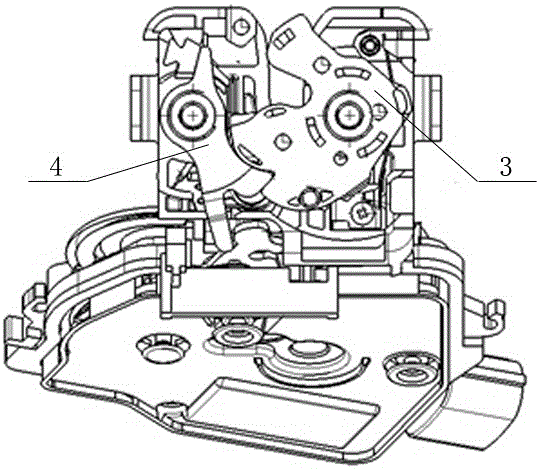

[0014] A tailgate lock assembly , including a cover plate 1, the lower part of the cover plate 1 is connected with the connecting plate 11 through the lock body 2, the middle part of the lock body 2 is provided with an open slot, and the rear end of the open slot is provided with a lock shock absorbing pad 8, and the left side of the open slot The lock body shock absorber 10 is provided, the door light signal conductive sheet 13 is provided on the right side of the opening slot, the self-tapping screw A14 is installed on the lock body 2, and the left part of the cover plate 1 and the left part of the lock body 2 is provided with a Ratchet 3, ratchet 3 is connected with cover plate 1 through ratchet shaft 5, ratchet return spring 6 is arranged between ratchet 3 and lock body 2, ratchet return spring 6 is located at the outer ring of ratchet sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com