Cross drilling constrained expansion network anti-reflection gas drainage method

A technology of gas drainage and network, which is applied in the fields of gas drainage and coal-rock gas drainage, and can solve problems such as poor gas drainage effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Due to the thick coal seam, high gas content, low permeability, and poor air permeability of the 15# coal seam in a mine, although the conventional gas drainage method has been tested many times, it is difficult to significantly improve the gas drainage effect. poor.

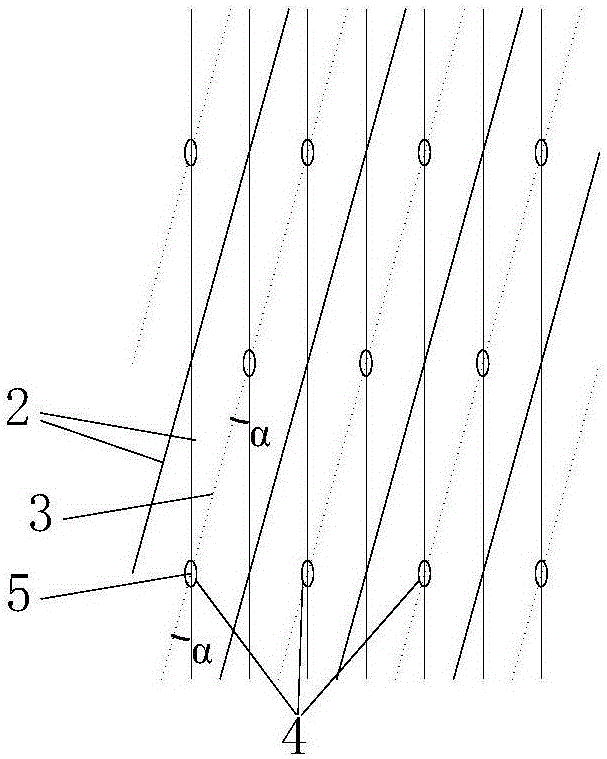

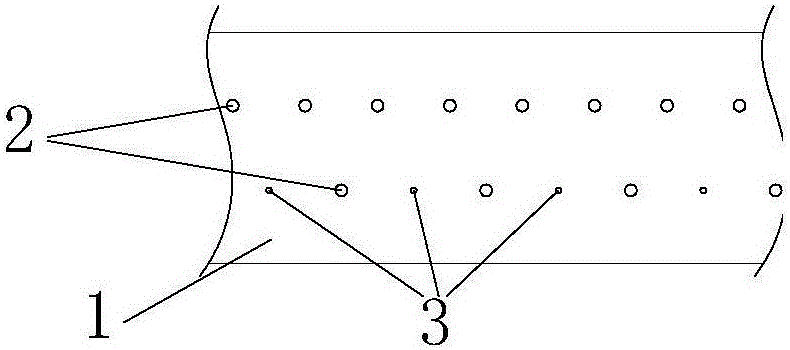

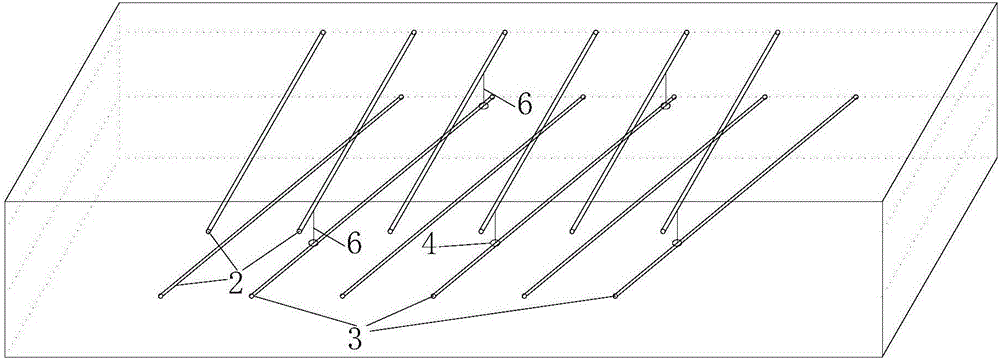

[0022] According to the coal seam thickness, coal seam inclination, gas content, gas pressure, coal seam permeability and other parameters of the mine construction site, design and construction cross drilling, each drilling hole is arranged horizontally. The upper row implements layer-by-layer drilling as gas drainage drilling, with a radius of R=90mm and a hole depth of D=60m; Hole radius R = 90mm, hole depth D = 60m, blast hole radius r = 50mm, hole depth d = 65m; the distance between the upper row of drill holes and the lower row of drill holes is 2.5m, and the oblique drill holes and bedding drill holes are projected on the horizontal plane Angle α = 20°, drilling spacing M = 3m. The number of cross...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com