A self-rotating dust-removing device for a dust-proof mesh cover of an engine water tank

A technology of dust-proof net cover and dust removal device, which is applied in the direction of engine cooling, engine components, machines/engines, etc., which can solve the problems of reduced work efficiency, poor ventilation, and waste of labor, so as to increase work efficiency and improve utilization rate , good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment,

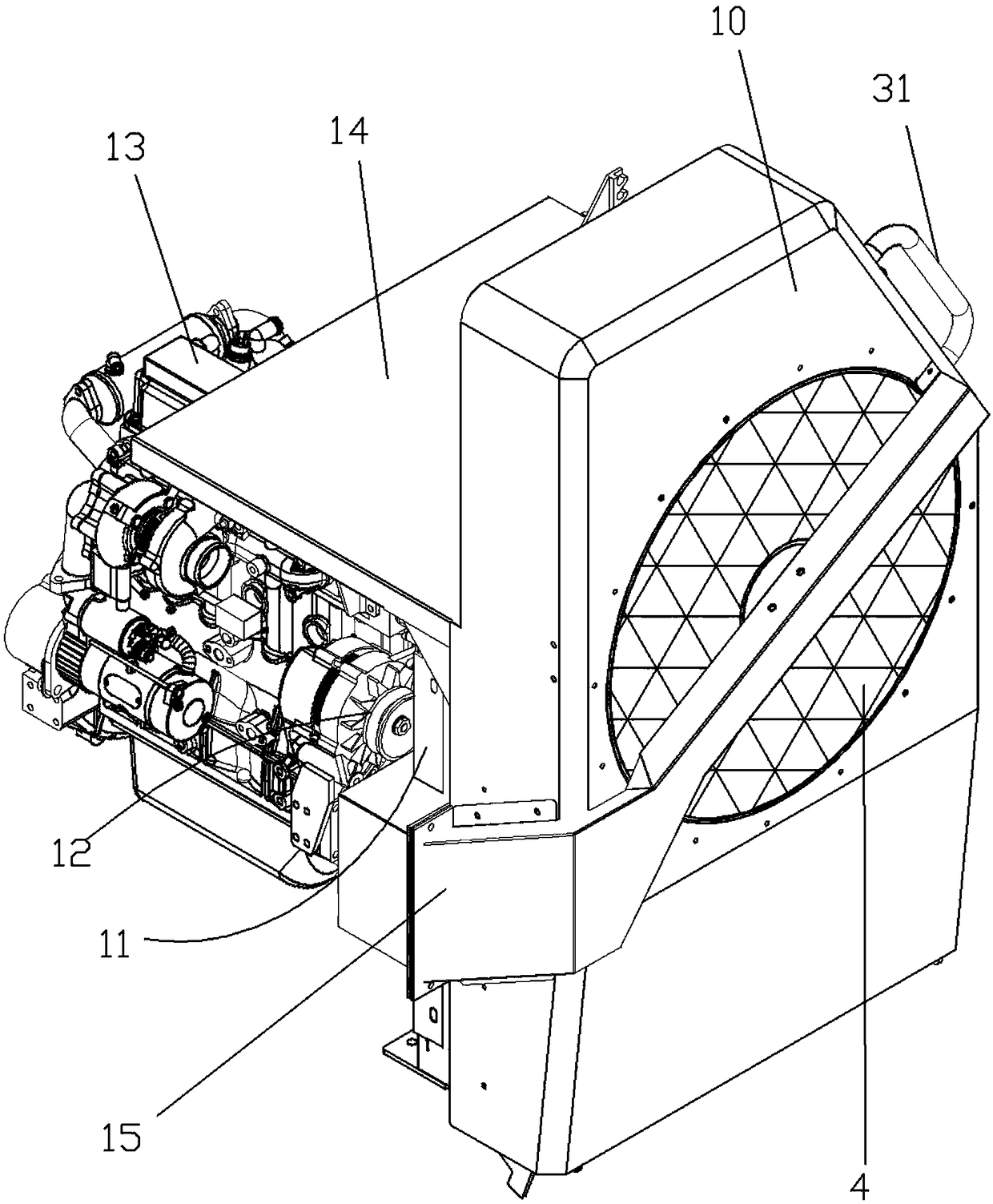

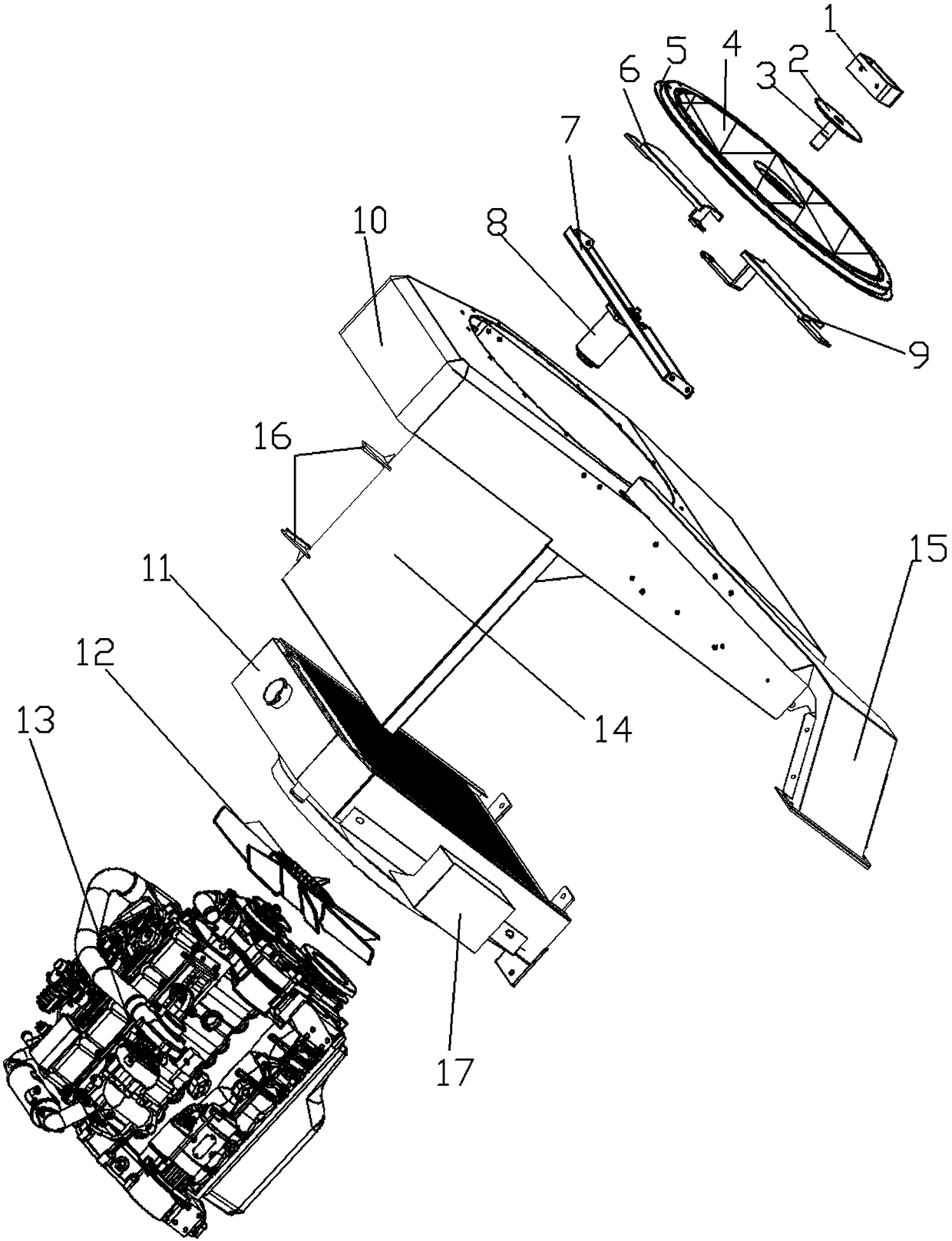

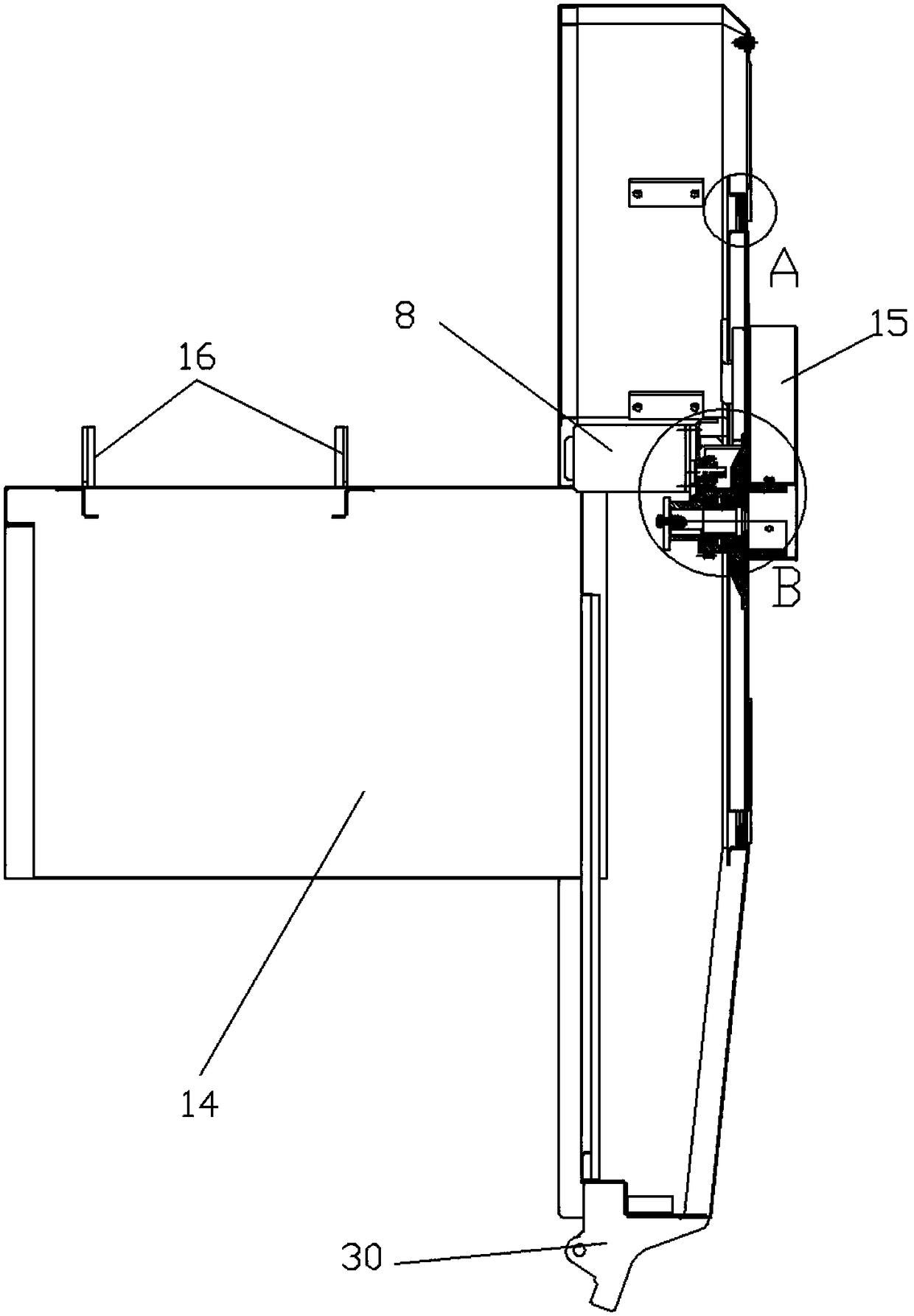

[0031] See figure 1 , figure 2 Shown: a self-rotating dedusting device of an engine water tank dustproof mesh cover, comprising a dustproof mesh cover 10, the dustproof mesh cover 10 is covered on the front side of the engine water tank 11, and an engine 13 is arranged at the rear of the engine water tank 11. An impeller 12 is arranged between the engine 13 and the engine water tank 11, and the impeller 12 is installed on the output end of the engine; the middle part of the dustproof net cover 10 is provided with a mounting hole, and a rotating turntable 4 is arranged in the mounting hole, and the rotating turntable 4 A heat dissipation through hole is formed, and a dust suction device 15 is arranged on the front side of the rotary turntable 4, and the dust suction device 15 starts from the rotary turntable 4 and crosses the rotary turntable 4, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com