Steam valve assembly and stewing cooker

A technology of steam valve and steam valve seat, which is used in steam traps, valve devices, kitchen utensils, etc., and can solve the problems of bubbling at the steam outlet, unable to meet the requirements of reflux replenishment, and liquid overflow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] It should be noted that, in the case of no conflict, the embodiments and features in the embodiments of the present invention can be combined with each other.

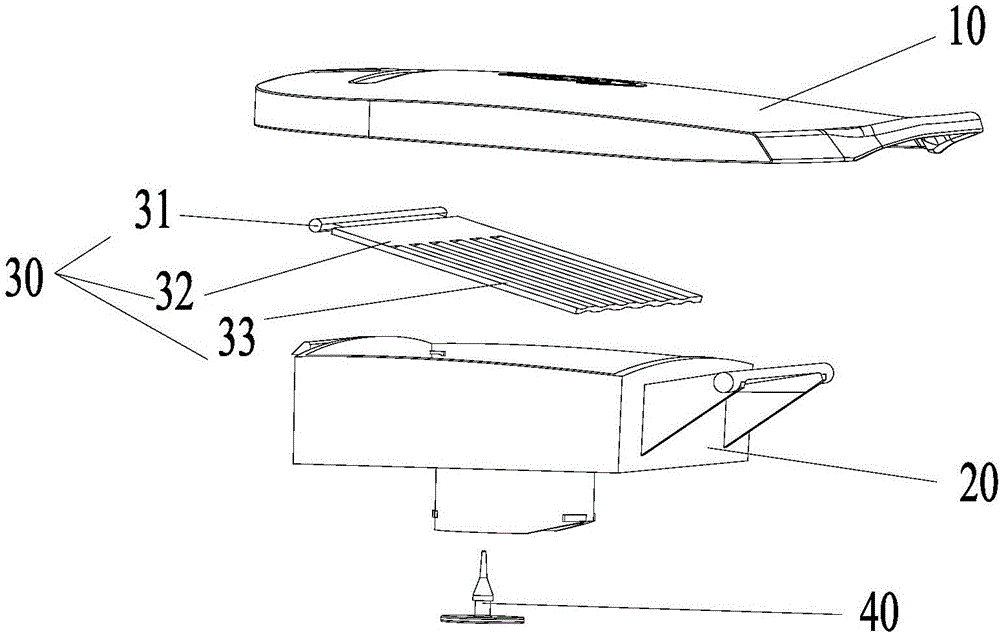

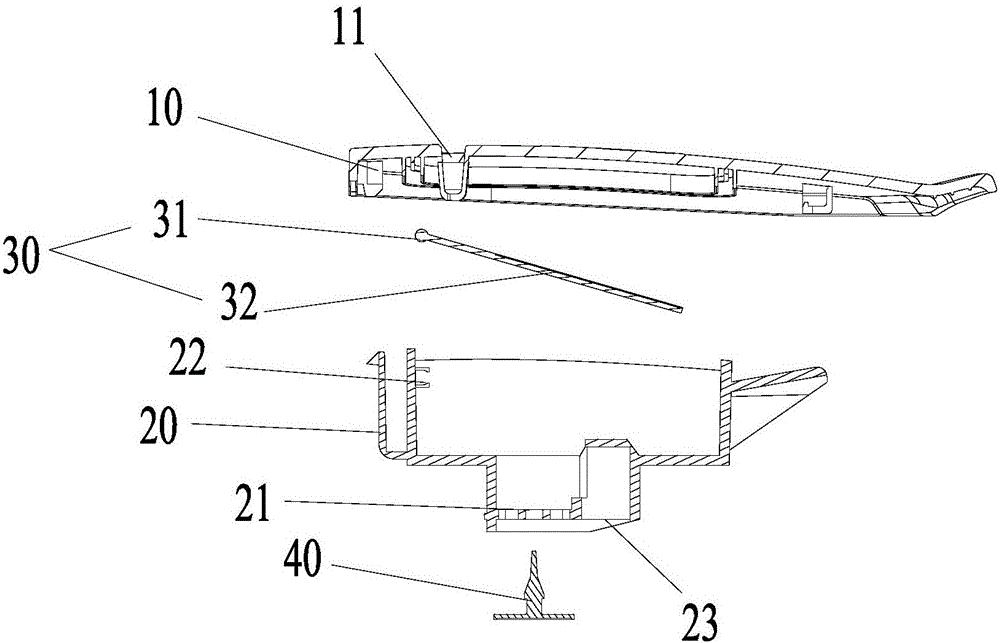

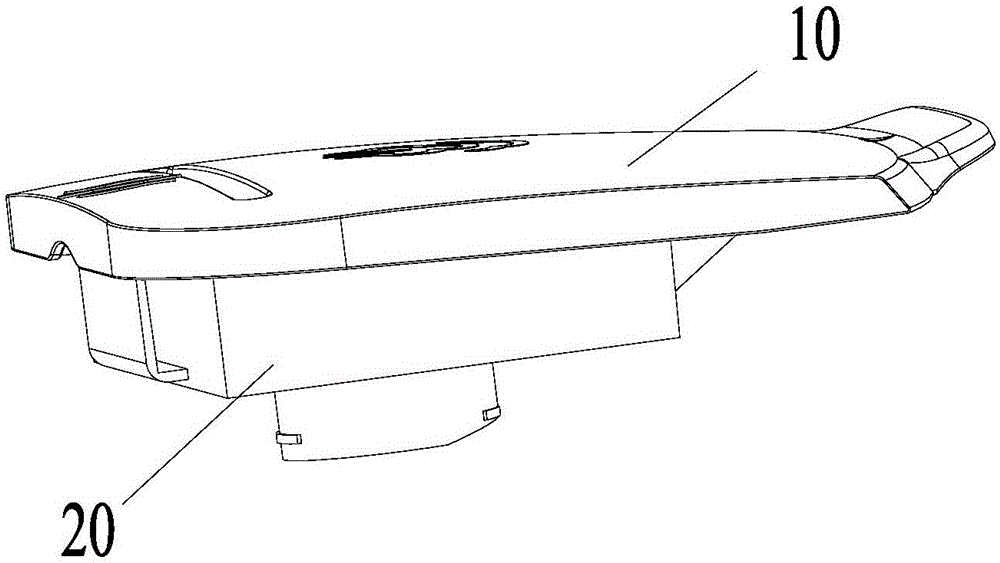

[0033] A steam valve assembly, characterized in that the steam valve assembly includes a steam valve cover 10, a steam valve seat 20 and a partition 30, the steam valve cover 10 is provided with a steam outlet 11, the steam valve seat 20 The bottom is provided with an air inlet 23, the steam valve cover 10 is connected with the steam valve seat 20 and defines a steam cavity between the steam valve cover 10 and the steam valve seat 20, and the partition 30 is arranged on The steam chamber is divided into a first chamber 50 communicated with the air inlet 23 and a second chamber 60 communicated with the steam outlet 11, the partition 30 is connected with the A gap is provided between the inner walls of the steam chamber.

[0034] Wherein, the steam valve cover 10 and the steam valve seat 20 can be connected in va...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap