Ammonia charging method for solid ammonia storage tank

An ammonia storage tank and solid technology, which is applied in the field of ammonia filling of solid ammonia storage tanks, can solve the problems of difficulty in controlling the amount of ammonia filling, low efficiency, long time for ammonia filling, etc., so as to improve the efficiency of ammonia filling, ensure the quality of ammonia filling, The effect of accelerating the rate of ammonia filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Make a solid ammonia storage tank, place it on the operating site, and turn on the liquid ammonia evaporation system. The predetermined temperature is 50°C, and the system reaches the predetermined pressure of 0.6MPa. When the predetermined vacuum degree is -0.08MPa, the air in the solid ammonia storage tank is completely exhausted.

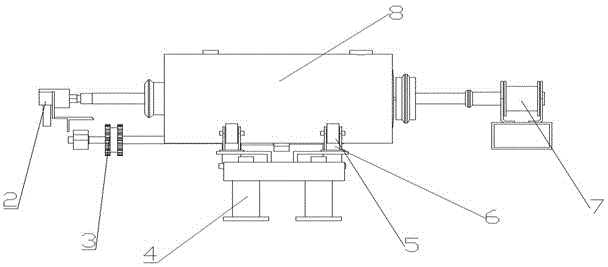

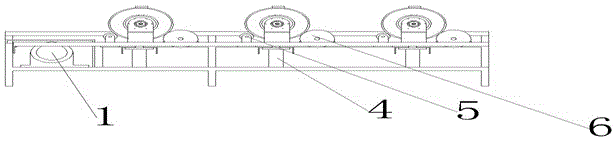

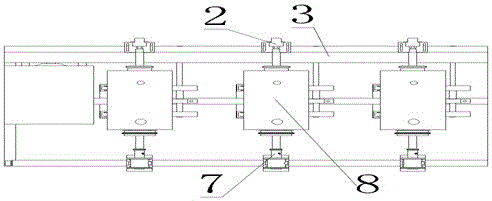

[0030] Use special hoisting equipment to place the solid ammonia storage tank on the machine to vibrate, connect the cooling water pipeline, the temperature of the cooling water is 14°C, connect the ammonia gas pipeline, and make sure there is no leakage point. At this time, the ammonia filling starts and ends after 20 hours. Reach 97.2% of the theoretical ammonia filling value. Such as Figure 4 shown.

Embodiment 2

[0032] Make a solid ammonia storage tank, place it on the operating site, and turn on the liquid ammonia evaporation system. The predetermined temperature is 55°C, and the system reaches the predetermined pressure of 0.8MPa. When the predetermined vacuum degree is -0.09MPa, the air in the solid ammonia storage tank is completely exhausted.

[0033] Use special hoisting equipment to place the solid ammonia storage tank on the shelf, connect the cooling water pipeline, the temperature of the cooling water is 15°C, connect the ammonia gas pipeline, and make sure there is no leakage point. At this time, the ammonia filling starts and ends after 25 hours. Reach 99% of the theoretical ammonia filling value. Such as Figure 5 shown.

Embodiment 3

[0035] Make a solid ammonia storage tank, place it on the operating site, and turn on the liquid ammonia evaporation system. The predetermined temperature is 60°C, and the system reaches the predetermined pressure of 0.75MPa. When the predetermined vacuum degree is -0.09MPa, the air in the solid ammonia storage tank is completely exhausted.

[0036] Use special hoisting equipment to place the solid ammonia storage tank on the machine to vibrate, connect the cooling water pipeline, the temperature of the cooling water is 15°C, connect the ammonia gas pipeline, and make sure there is no leakage point. At this time, the ammonia filling starts and ends after 20 hours. Reach 95% of the theoretical ammonia filling value. Such as Figure 6 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com