Ammoniating method for solid ammonia storage tank

An ammonia storage tank and solid technology, which is applied in fixed-capacity gas storage tanks, gas/liquid distribution and storage, fluid processing, etc. Adverse consequences, saving filling time, and accelerating the effect of adsorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

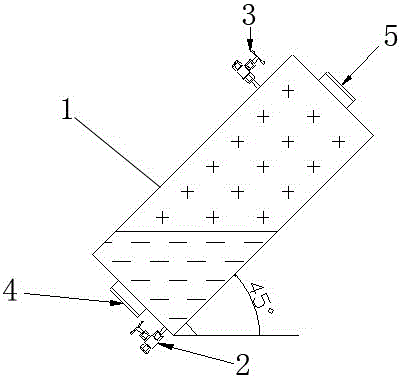

[0023] Make a solid ammonia storage tank 1 and place it on a static shelf, such as figure 1 As shown, connect the cooling water pipeline, the cooling water temperature is 12°C, connect the ammonia gas pipeline, and make sure there is no leakage point. At this time, start to fill the ammonia, finish filling after 1h, put it in a constant temperature water bath at 12°C, and cool and adsorb for 7-8h , the pressure inside the tank is 0Mpa, which means the filling is over.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com