Rapid bed material adding system of boiler

A technology of adding bed materials and boilers, applied in the field of fluidized bed boilers, can solve the problems of many maintenance items, high energy consumption, long time consumption, etc., and achieve the effect of avoiding dust flying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

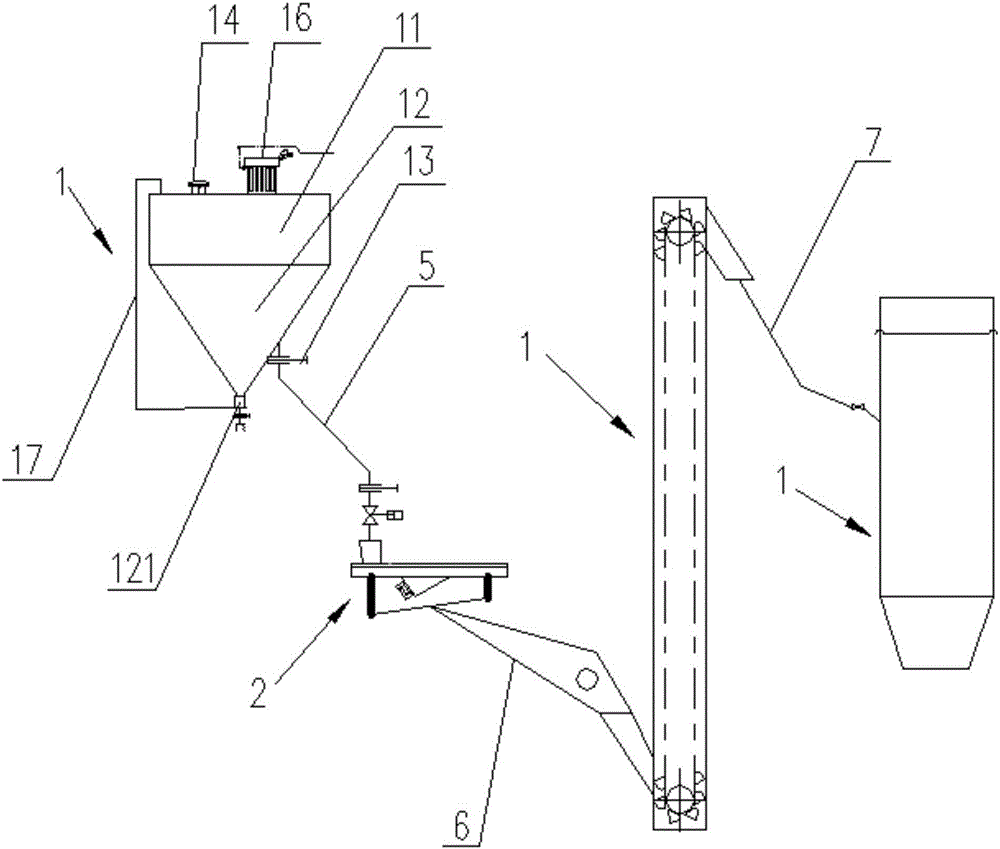

[0021] Such as figure 1 As shown, a boiler rapid bed material addition system is characterized in that it includes a slag bin 1, a screening mechanism 2, and a lifting mechanism 3; the slag bin 1 is connected to the screening mechanism 2 through a first pipeline 5; the screening mechanism 2 passes through The second pipeline 6 is connected with the lifting mechanism 3; the lifting mechanism 3 transports the coal slag to the boiler 4 through the material guide device 7.

[0022] The upper part of the slag bin 1 is a cylindrical section 11, and the lower part is a conical section 12. A bed material outlet is provided at the middle and lower part of the conical section 12; the outlet is connected to the first pipeline 5, and a gate valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com