Air conditioner oil returning device

A technology for air conditioners and oil return pipes, applied in lighting and heating equipment, compressors, fluid circulation arrangements, etc., can solve the problems of increasing circulation resistance, reducing cooling capacity, and slowing down the return speed of lubricating oil, so as to ensure fluidity, Improve cooling capacity and unobstructed air return

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

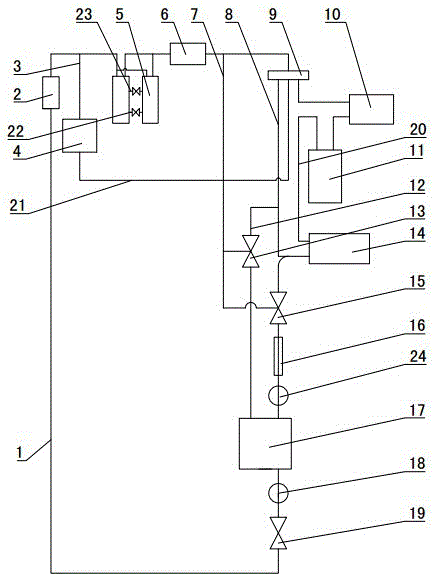

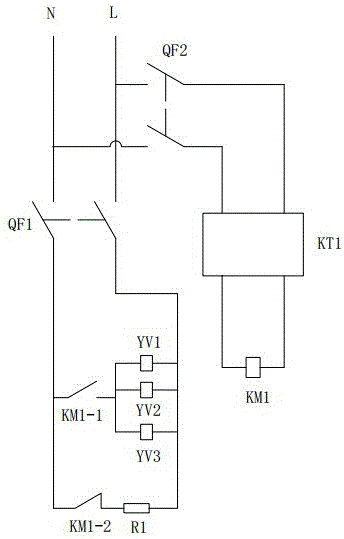

[0032] Figure 1~2 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~2 The present invention will be further described.

[0033] An air conditioner oil return device, comprising a compressor 5, an oil separator 6, a four-way valve 9, a condenser 10 and an evaporator 14, the oil separator 6 is arranged between the compressor 5 and the condenser 10, and the evaporator 14 The refrigerant outlet communicates with the four-way valve 9 through the air return pipe 8, and the refrigerant inlet of the compressor 5 communicates with the four-way valve 9 through the suction pipe, and also includes an oil reservoir 17, and the oil inlet of the oil reservoir 17 is connected to the reversing unit in series. The upper air return pipe 8 communicates with the return air pipe 8 and keeps a normally open state. The pipeline between the refrigerant outlet of the oil separator 6 and the refrigerant outlet of the evaporator 14 communicates with the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com