Wireless passive real-time temperature measuring sensing apparatus, system, and method for cable joint

A cable joint and sensing device technology, applied in the field of power equipment, can solve the problems of large difference between the temperature value and the actual temperature value, frequent battery replacement, high temperature resistance, etc., to achieve accurate measured temperature value and avoid weak signal transmission. , to avoid the effect of false temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

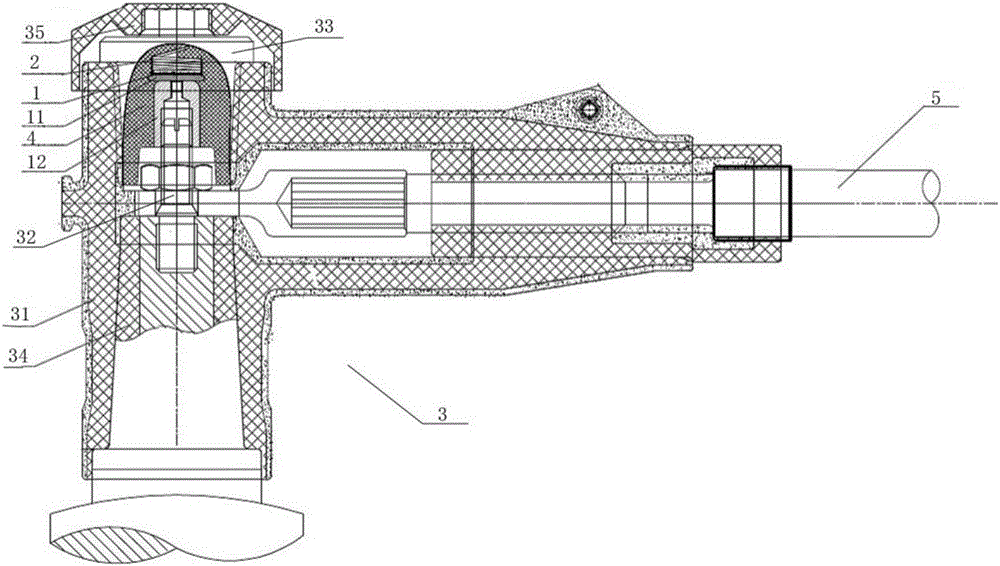

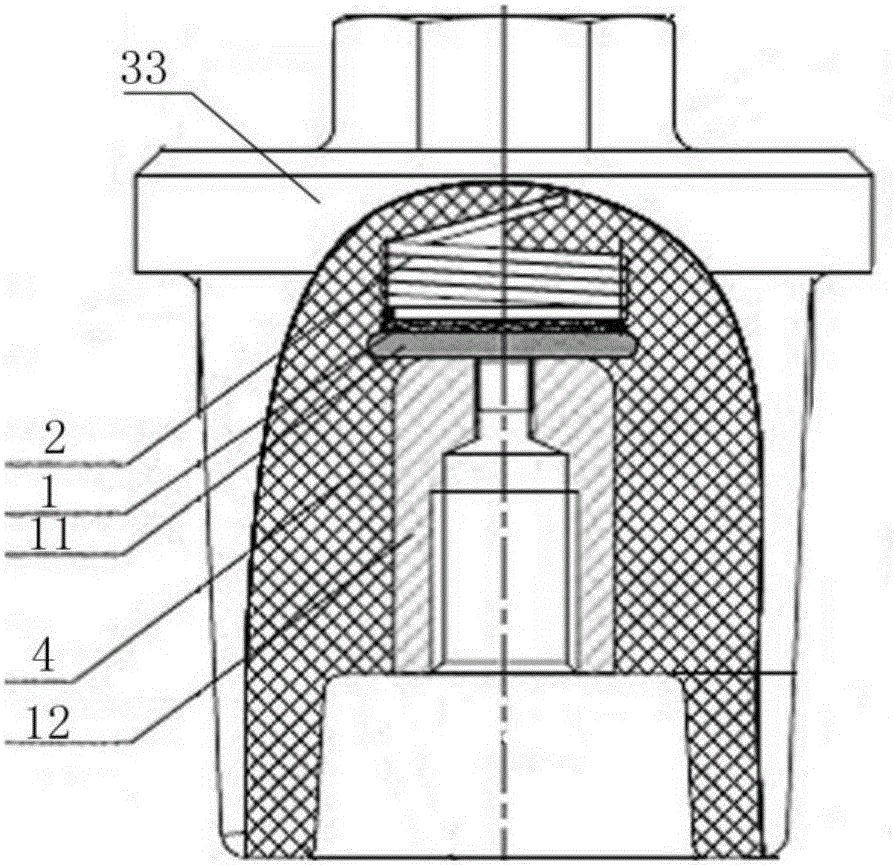

[0041] Such as figure 1 with figure 2 As shown, a cable joint wireless passive real-time temperature measurement sensor device in this embodiment includes a temperature sensor 1 and an antenna 2, and the temperature sensor 1 and the antenna 2 are embedded in the place through an epoxy resin 4 injection curing molding process. In the cable joint 3, the temperature sensor 1 is in contact with the wires in the cable joint 3, and the antenna 2 is fixed on the temperature sensor 1 and communicated with it. The cable joint 3 is connected to one end of the cable 5 and conducts with the wires in the cable 5 .

[0042] In the embodiment of the present invention, the temperature sensor and the antenna are embedded in the cable joint through the epoxy resin injection curing molding process, so that the temperature sensor is in contact with the wire in the cable joint, that is, the temperature sensor is directly in contact with the high-voltage end of the cable joint, and the temperatur...

Embodiment 2

[0053] A kind of temperature sensing system of the present embodiment comprises:

[0054] The temperature collector is used to send temperature acquisition signals, and is also used to receive and send temperature signals;

[0055] The temperature measuring and sensing device as described in Embodiment 1 is used to receive and process the temperature acquisition signal, obtain a temperature signal and send the temperature signal to the temperature collector;

[0056] The terminal device is used to receive and display the temperature signal sent by the temperature collector.

[0057] Every temperature response time T, the terminal device is also used to control the temperature sensor to send a temperature collection signal, and within the preset time after the temperature sensor sends the temperature collection signal, the terminal device does not receive the temperature signal, the terminal equipment sends out an alarm signal.

[0058] The terminal device is also used to com...

Embodiment 3

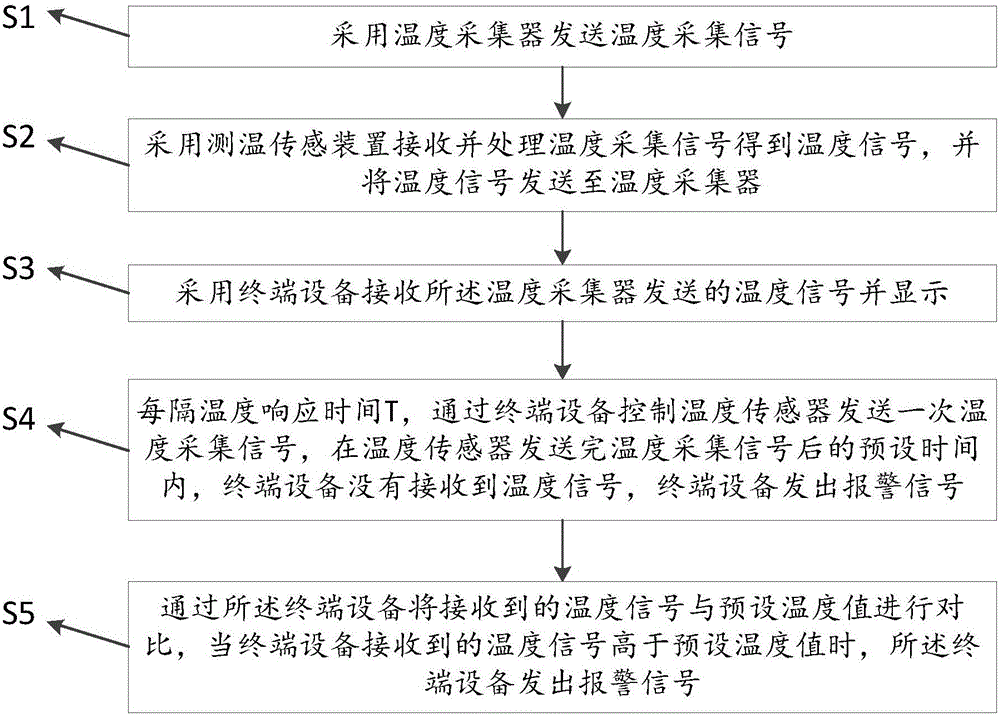

[0063] Such as image 3 As shown, a temperature sensing method of the present embodiment includes the following steps:

[0064] Step S1, using a temperature collector to send a temperature acquisition signal;

[0065] Step S2, using the temperature sensing device as described in Embodiment 1 to receive and process the temperature acquisition signal, obtain a temperature signal and send the temperature signal to the temperature collector;

[0066] Step S3, using a terminal device to receive and display the temperature signal sent by the temperature collector.

[0067] Step S4, every temperature response time T, the terminal device controls the temperature sensor to send a temperature collection signal, and the terminal device does not receive the temperature collection signal within a preset time after the temperature sensor sends the temperature collection signal. temperature signal, the terminal equipment sends out an alarm signal;

[0068] In step S5, the terminal device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com