LED brightness test adjustment device and system

A technology for adjusting devices and brightness, which is applied in measuring devices, testing optical properties, and testing individual semiconductor devices. It can solve problems such as gear switching errors, decreased test accuracy, and limited adjustment gears, achieving high accuracy and improving efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The preferred embodiments of the invention will be further described in detail below.

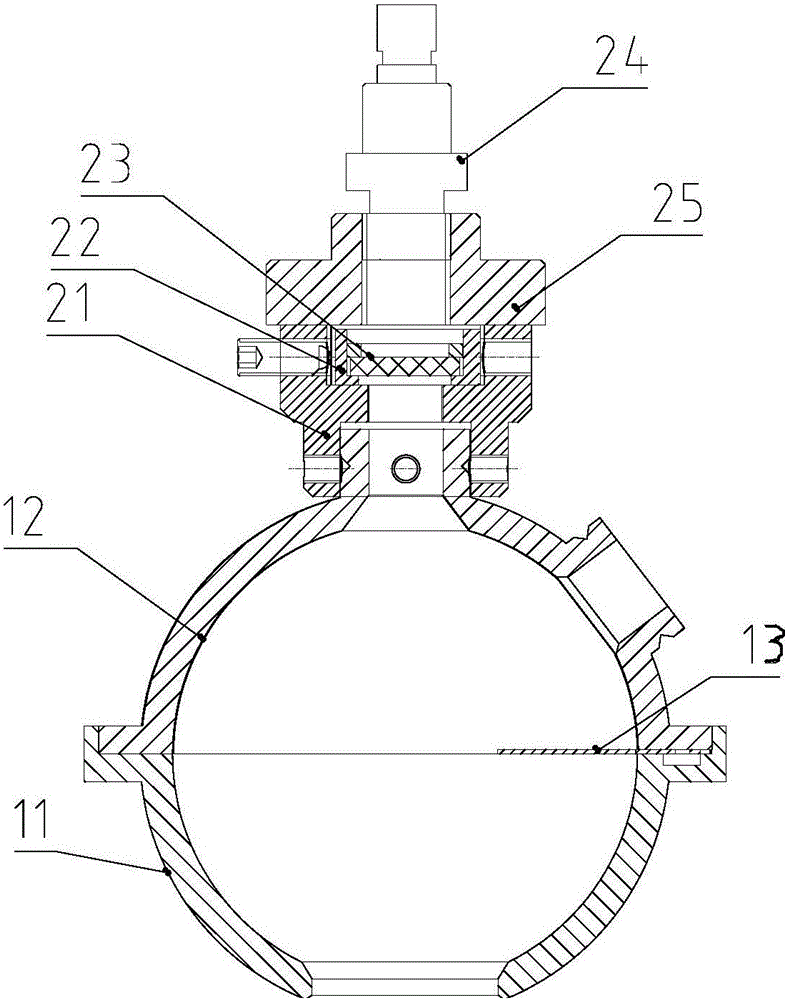

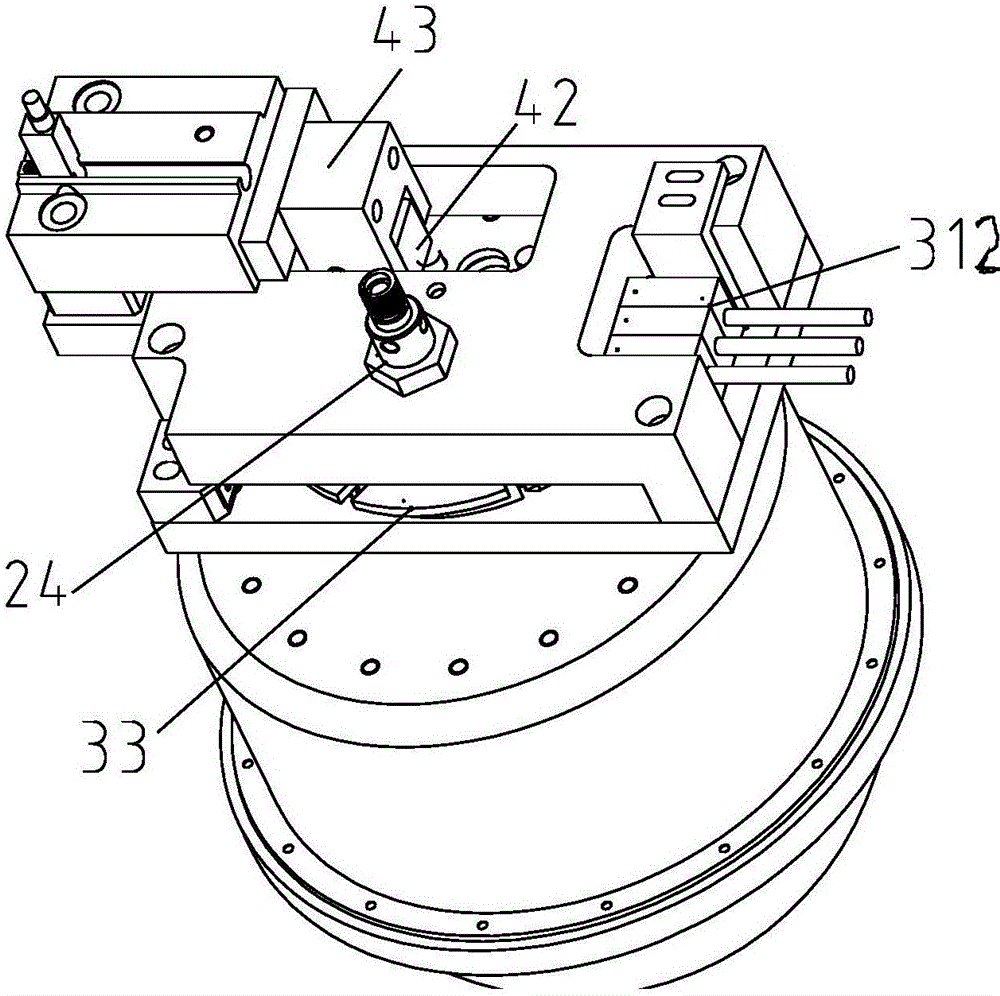

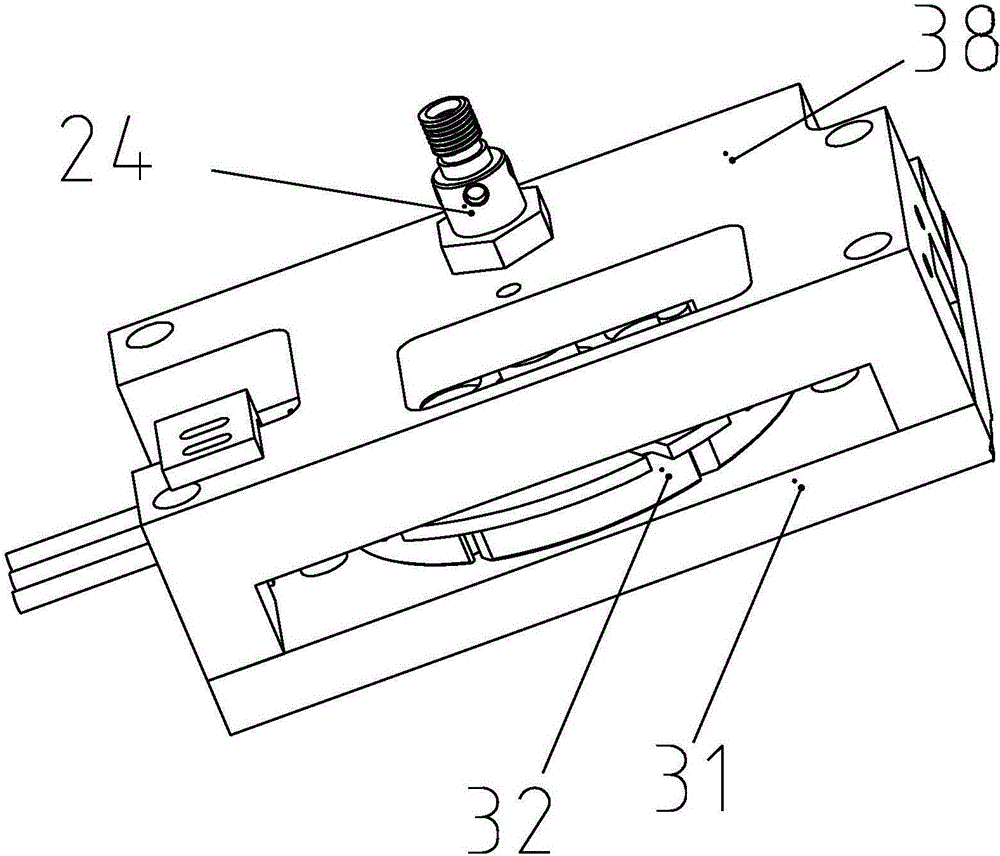

[0028] Such as Figures 1 to 9 As shown, an embodiment of the LED brightness test adjustment device includes: a drive assembly, a light attenuating sheet mount 32, a sensor 312, and a plurality of light attenuating sheets 37 with different degrees of light attenuation. The light attenuating sheet mount 32 The corresponding light-attenuating sheet 37 is installed in different positions (the light-attenuating sheet mounting seat 32 can be provided with a light-attenuating sheet hole, and the light-attenuating sheet 37 is installed in the light-attenuating sheet hole), that is to say, each different light-attenuating sheet 37 and The different positions of the light attenuating sheet mounting base 32 correspond one to one.

[0029] When working, the driving assembly drives the light attenuating sheet mounting seat 32 to rotate, and the rotation of the light attenuating sheet mounting s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com