All-electric ground strength testing device

A strength detection, all-electric technology, applied in the field of measurement, can solve the problems that cannot truly reflect the bearing capacity, system oil leakage, long detection cycle, etc., and achieve the effect of quickly and accurately detecting the ground pressure strength and meeting the ground pressure requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

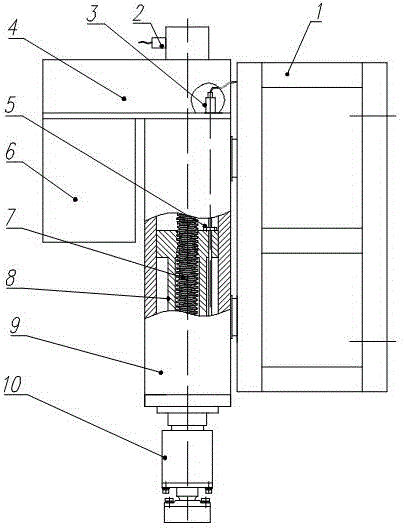

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

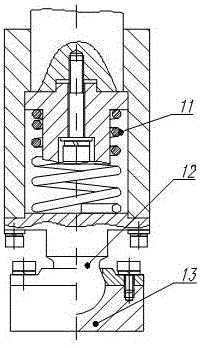

[0020] Such as figure 1 and figure 2 shown. The all-electric ground strength detection device of the present invention consists of a mounting frame 1, a pressure sensor 2, a displacement sensor 3, a transmission device 4, a magnetic ring 5, a servo motor 6, a ball screw 7, a piston rod 8, a cylinder barrel 9, and a transition sleeve 10 , Spring 11 and spring seat, force measuring contact 13 are formed. Wherein, the cylinder 9 is fixed on the side of the installation frame 1 , and the piston rod 8 is located in the cylinder 9 . The ball screw 7 is located in the piston rod 8 and is threaded with the piston rod 8 axis. The transmission device 4 is installed on the top of the cylinder barrel 9 and is connected with the ball screw 7 , and the servo motor 6 is installed on the transmission device 4 . The pressure sensor 2 is installed on the top of the ball ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com