A Simple and Practical Water Analyzer

A water analyzer, a practical technology, applied in the direction of instruments, scientific instruments, analytical materials, etc., can solve the problems of affecting the observation of grading effects, poor stability, and inconvenient operation, so as to achieve accurate and reliable test results, prevent medium overflow, and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

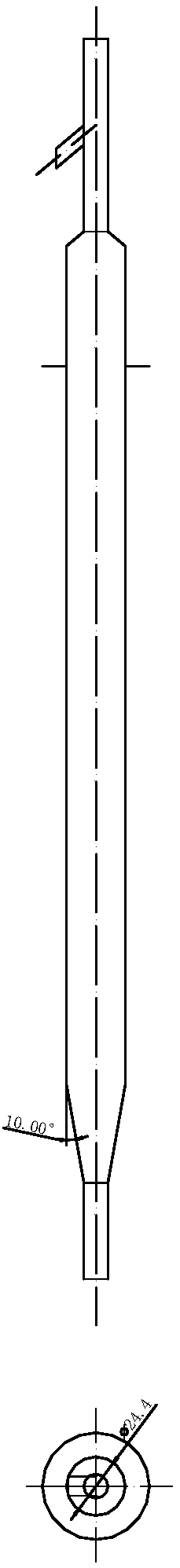

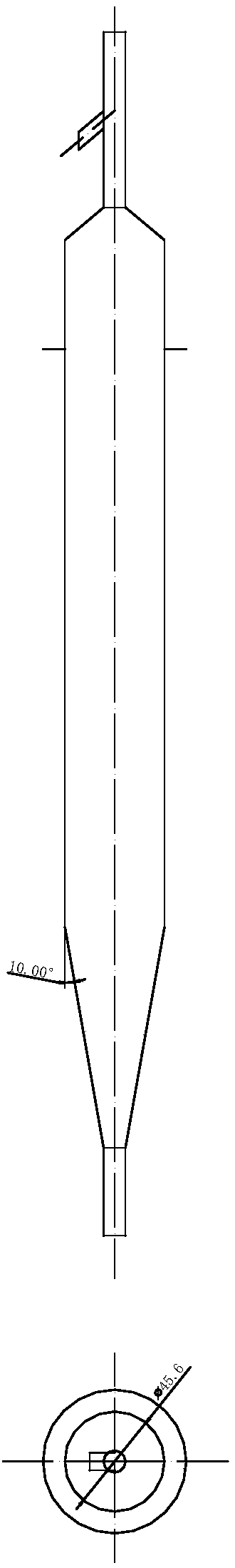

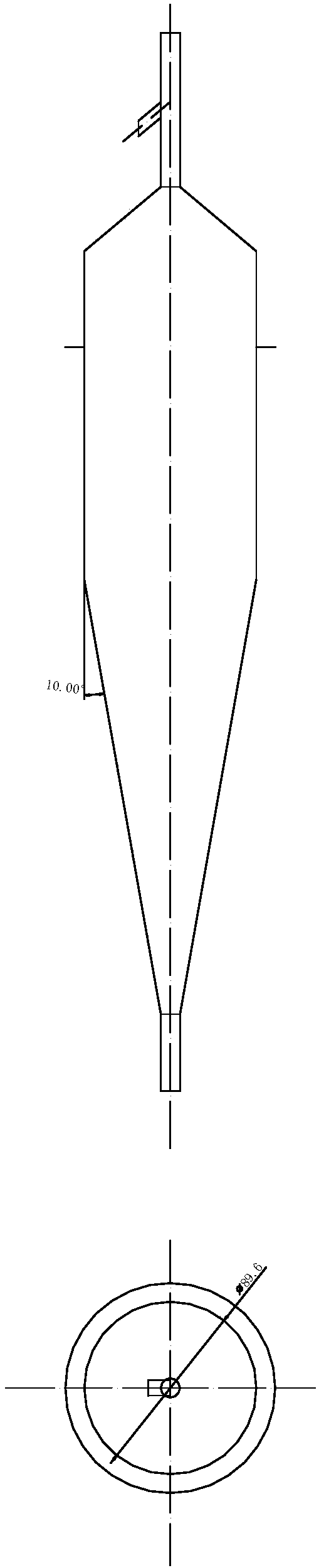

[0028] Such as figure 1 , figure 2 , Figure 3a , Figure 3b , Figure 3c , Figure 3d , Figure 4a , Figure 4b As shown, a simple and practical water analyzer, which includes a cross base 1, a hollow shaft 2, an upper and lower double-layer disc support 3, an upper tapered roller 4, a lower tapered roller, a telescopic pull rod 5, and a funnel support 6 , Classifier 9 that is easy to disassemble and clean, silicone tube 10, plexiglass tube 11;

[0029] The lower end of the hollow central shaft 2 is fixed on the cross base 1 (the cross base 1 is fixedly connected with the hollow central shaft 2); the outer edge of the upper end of the hollow central shaft 2 is provided with an upper tapered roller 4, the lower end of the hollow central shaft 2 The outer edge of the upper part is provided with a lower tapered roller (that is, two tapered rollers are arranged on the hollow central shaft 2), and the upper and lower double-layer disc support 3 is composed of an upper disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com