Simulation device for hydrothermal filling of fracture zones

A technology for simulating device and fracture zone, applied in the field of fracture zone hydrothermal filling simulation device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

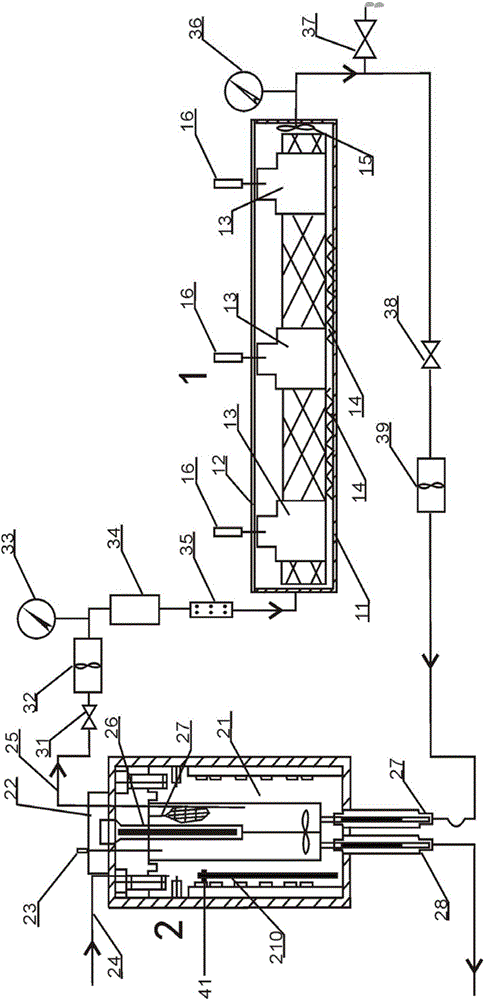

[0014] As shown in Figure 1, the simulation device for hydrothermal filling in the fracture zone includes: mineral crystallization-precipitator 1, magnetic stirring reactor 2; Configure saturated chemical reaction hot liquid, through heating, pressurization, acceleration, saturated chemical reaction hot liquid enters the rock cracks in the mineral crystallization-sedimentator for chemical precipitation, and the undersaturated hot liquid after the reaction returns to the magnetic stirring reaction tank for re- Replenish chemical reagents to become a saturated solution and repeat the cycle.

[0015] Mineral crystallization-precipitator 1, including: precipitator 11, glass plate 12, card slot 13, heating wire 14, power pump 15; precipitator 11 is a cuboid container with length, width and height of 30cm×20cm×20cm, surrounded by And the bottom is made of stainless steel, and the top is closed by a glass plate 12. The glass plate 12 is a double-layer anti-explosion structure with go...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com