Momentum wheel simulator based on self-adaptive friction moment model

A technology of friction torque and momentum wheel, which is applied in the field of momentum wheel simulation, can solve the problems of error, error, closed-circuit test of momentum wheel application system, inability to accurately simulate the friction characteristics of momentum wheel, etc., and achieve flexible hardware structure and accurate friction torque characteristics Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

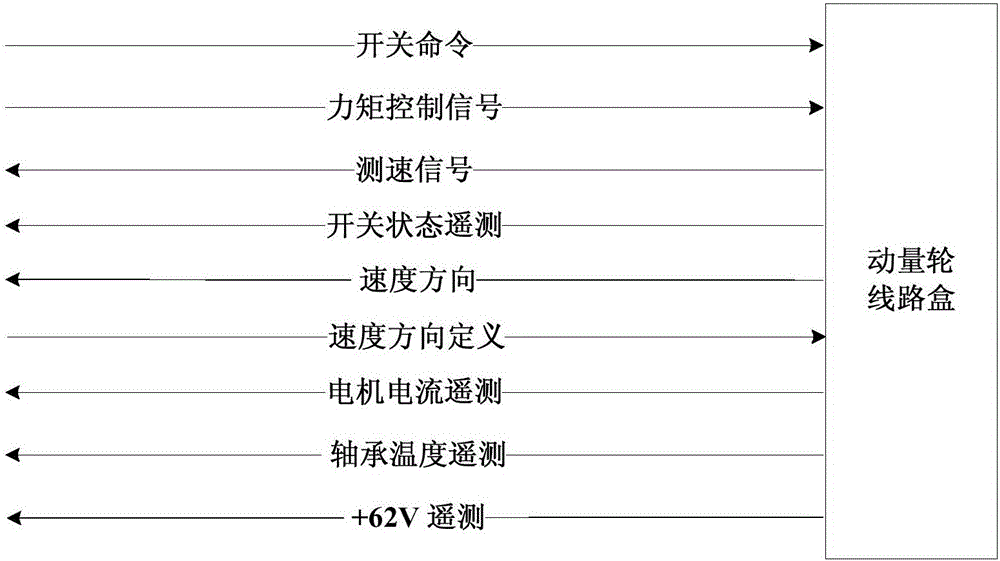

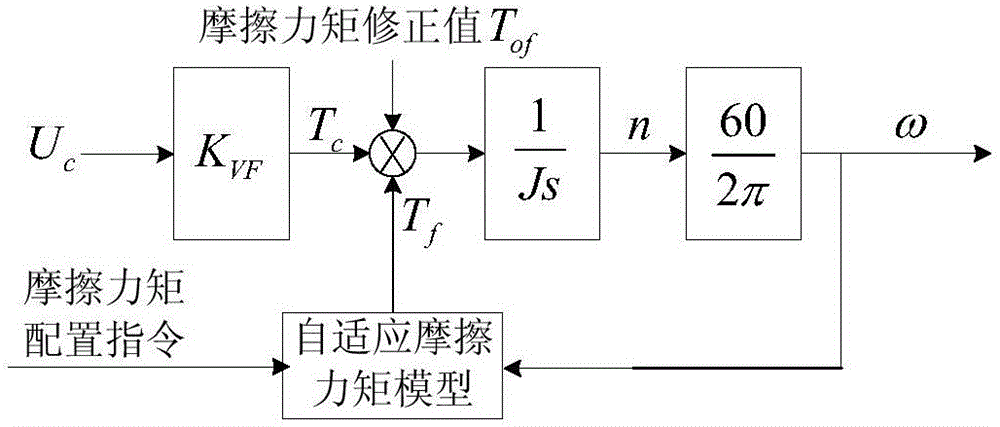

[0036] Aiming at the deficiencies in the prior art, the present invention proposes a momentum wheel simulator based on an adaptive friction torque model, by adopting a momentum wheel motion mathematical model based on an adaptive friction torque model, the appropriate The friction torque model accurately reflects the characteristics of the friction torque of the momentum wheel changing with the rotational speed. The simulator of the present invention will be described in detail below in conjunction with the accompanying drawings.

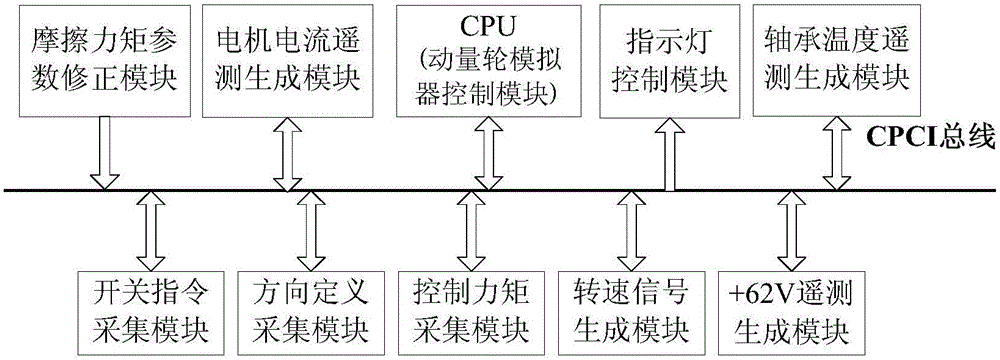

[0037] The momentum wheel simulator of the present invention comprises two key technologies: (1) based on the framework of the CPCI bus technology and the VxWorks real-time operating system, each functional module that the momentum wheel simulator comprises is all articulated in the running VxWorks real-time operating system by the CPCI bus On the CPU, each functional module can be freely configured to increase or decrease according to requirements. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com