A dsp soft error detection method based on difference transformation of linear assembly instructions

A technology of assembly instructions and detection methods, applied in the field of error detection, can solve problems such as high performance overhead

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

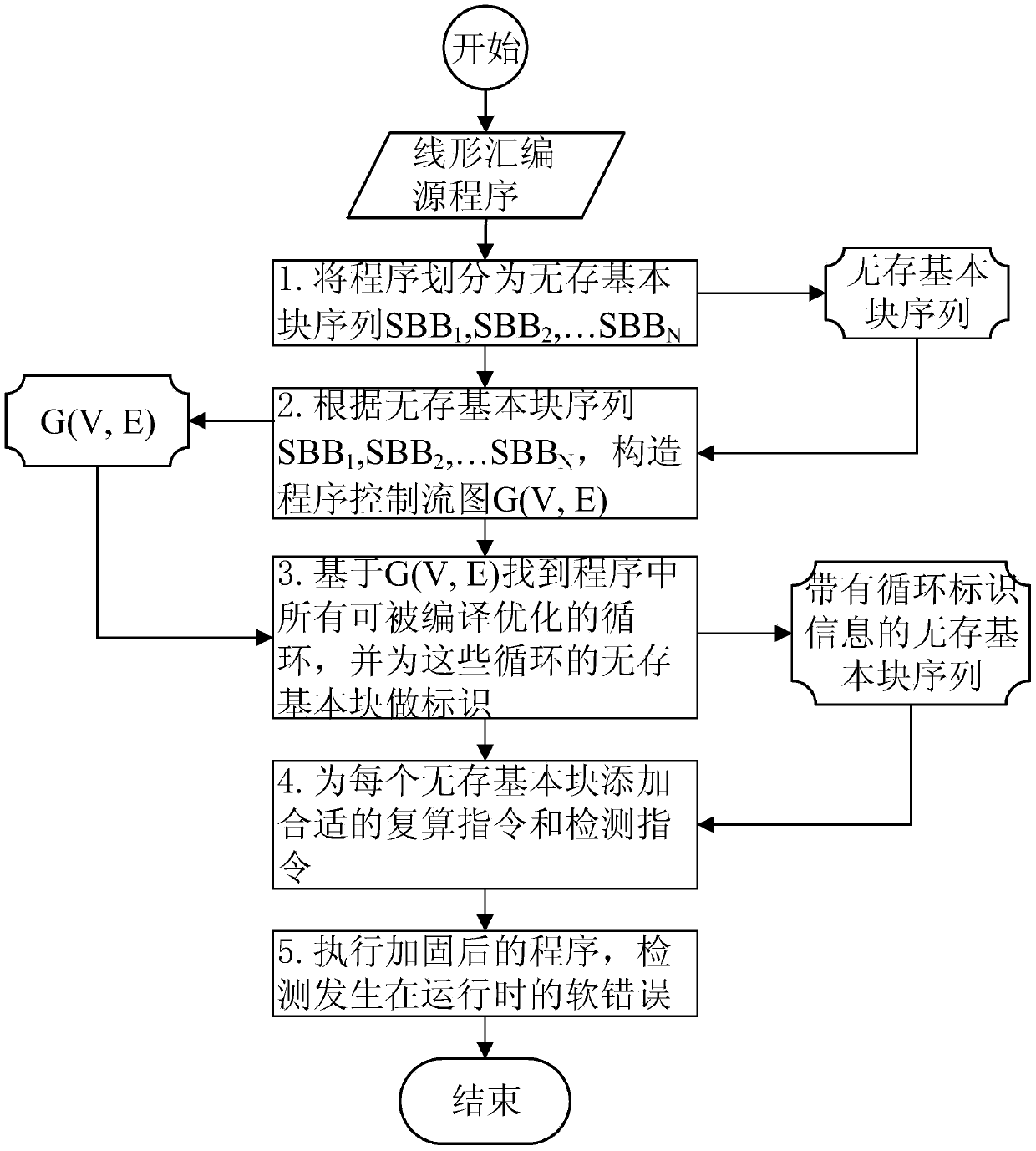

[0144] figure 1 It is a general flowchart of the present invention, mainly comprising the following five steps:

[0145] 1. Divide the linear assembly source program into non-storage basic block sequences SBB 1 ,SBB 2 ,…SBB N .

[0146] 2. Based on non-stored basic block sequence SBB1 ,SBB 2 ,…SBB N , Construct the program control flow graph G(V,E).

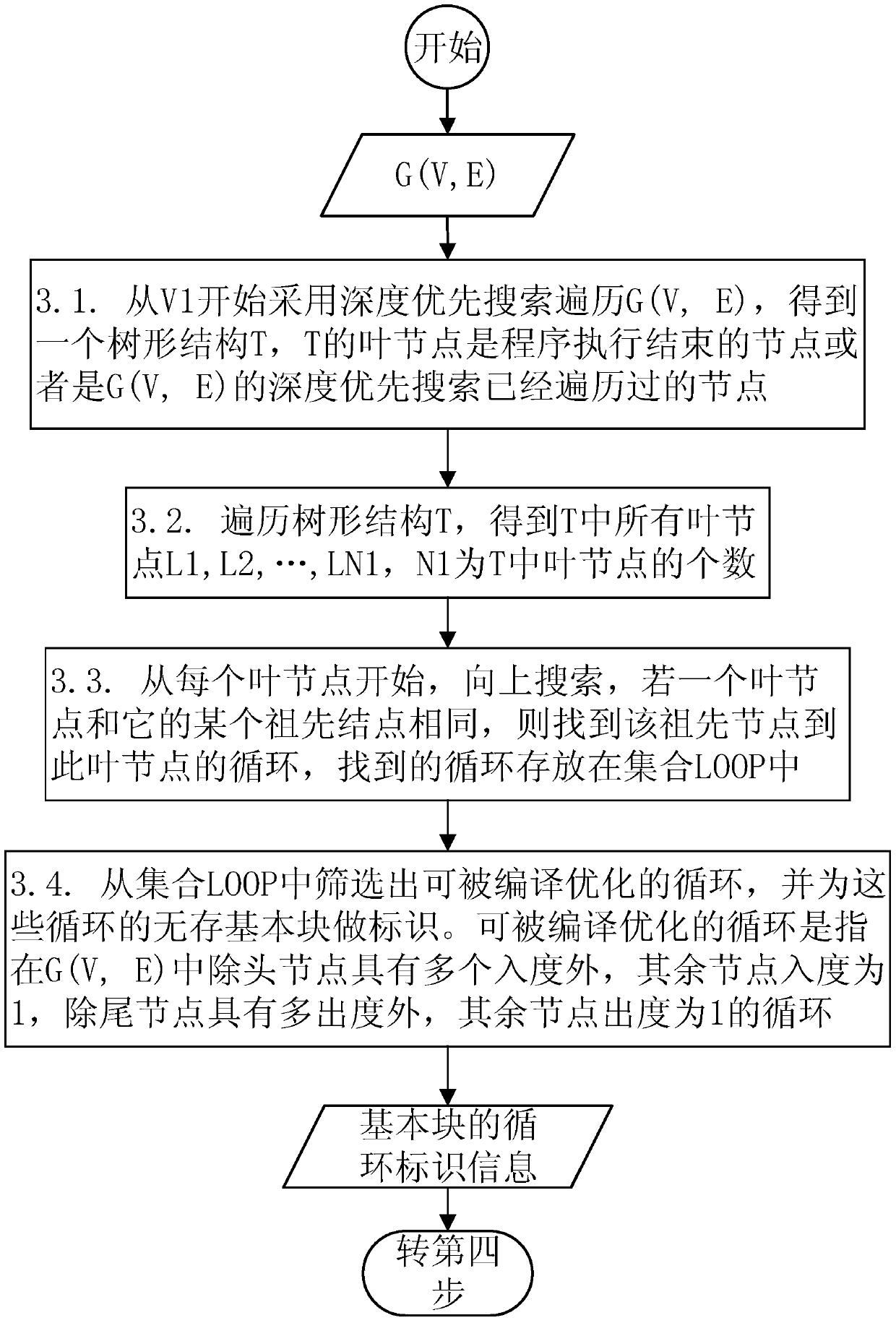

[0147] 3. Based on the program control flow graph G(V,E), find all loops in the program that can be compiled and optimized, and mark the non-existent basic blocks of these loops.

[0148] 4. Reinforce the program and add appropriate recalculation instructions and detection instructions for each non-memory basic block.

[0149] 5. Execute the hardened program and detect soft errors that occur during runtime.

[0150] Through the above five steps, the soft error detection of the DSP linear assembler can be realized.

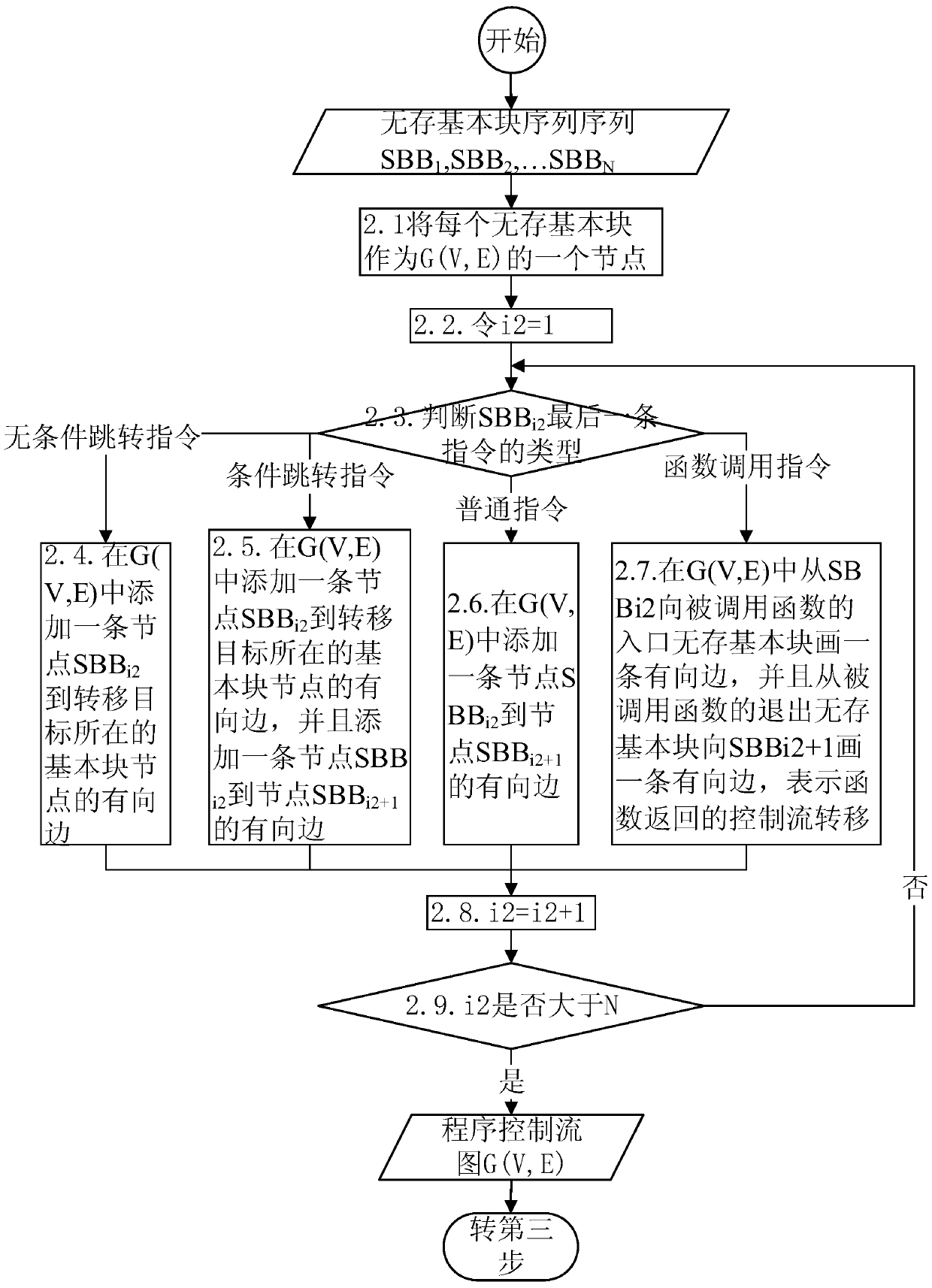

[0151] figure 2 is the second step of the present invention based on the non-deposited basic block seque...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com