Application of quick mechanism in combined on-load tap-changer

An on-load tapping and combined technology, which is applied to the power device and contact drive mechanism inside the switch, can solve the problems of increased manufacturing cost, many friction components, mechanical failure, etc., and achieve low manufacturing cost and small operating force , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The following examples further describe the present invention, but the examples are only for illustrating the present invention rather than limiting the present invention.

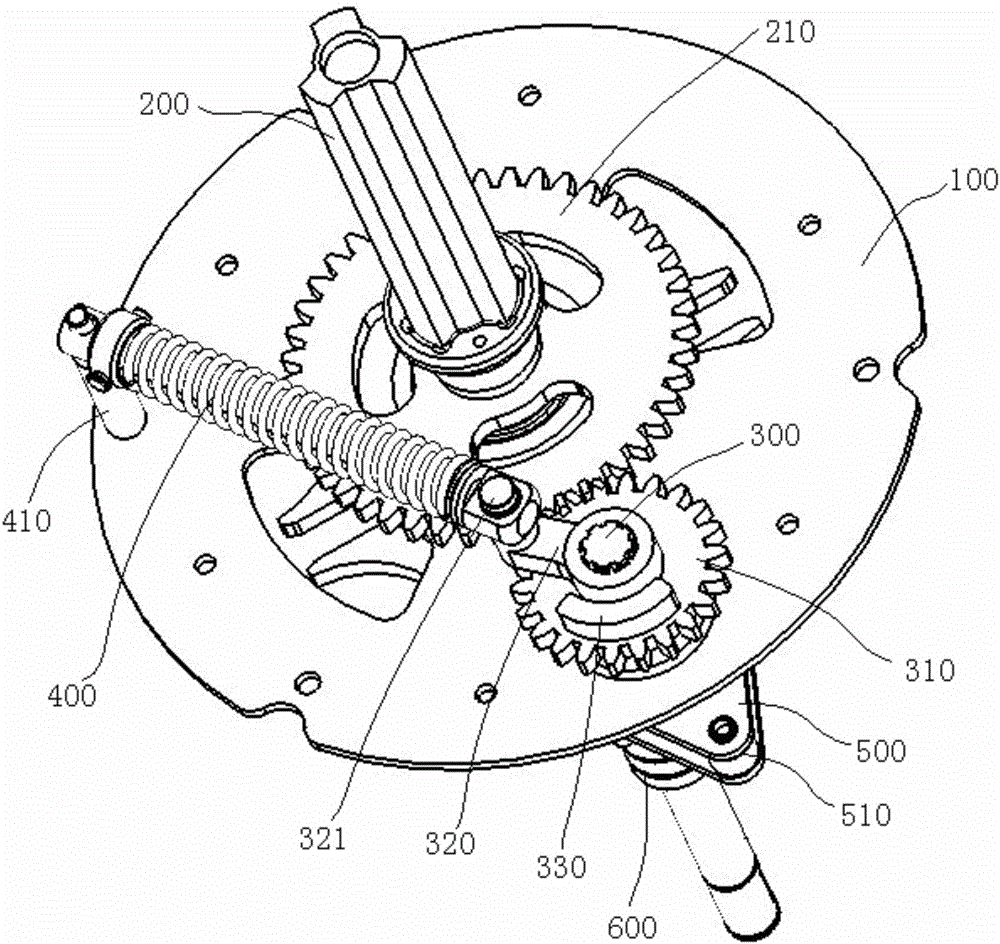

[0039] see image 3 and Figure 4 , the application of the fast mechanism shown in the figure in the combined on-load tap-changer, the fast mechanism includes a fixed plate 100, a triangular shaft 200, a driving gear 210, a countershaft 300, a driven gear 310, a crank arm 320, a spring 400 , lock wheel assembly 500 , sleeve shaft 600 and sheave 610 .

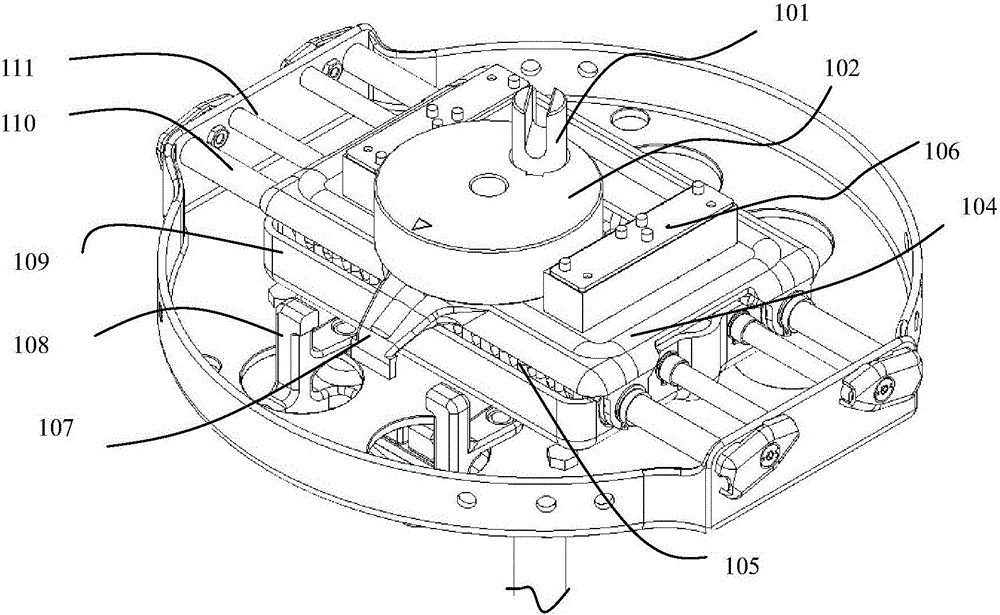

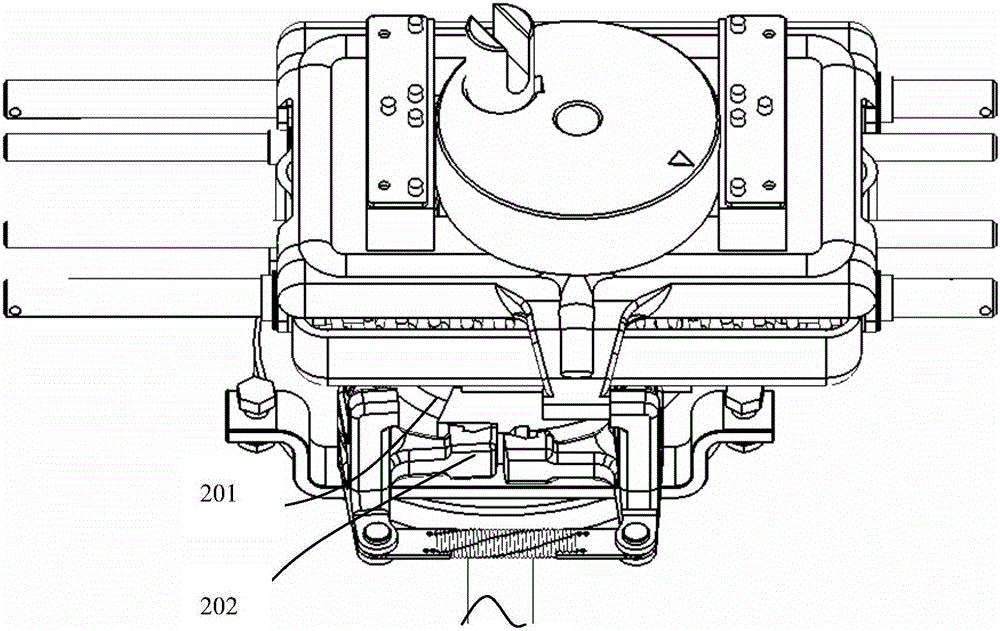

[0040] The fixing plate 100 is installed on the combined on-load tap-changer A (combined with see Figure 8 ), the triangular shaft 200 is set on the center of the fixed plate 100, and the triangular shaft 200 is driven by the electric mechanism (not shown in the figure) in the combined on-load tap changer A to rotate.

[0041] The driving gear 210 is fixed on the triangular shaft 200 and located above the fixing plate 100 . The auxiliary shaft 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com