Electronic fun for atmospheric electron beam machining equipment

An electron beam processing and electron gun technology, applied in the field of electron beam processing equipment, can solve the problems of reducing processing efficiency, restricting the processing of large workpieces, increasing the manufacturing cost and application energy consumption of electron beam processing equipment, etc. The effect of reducing energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

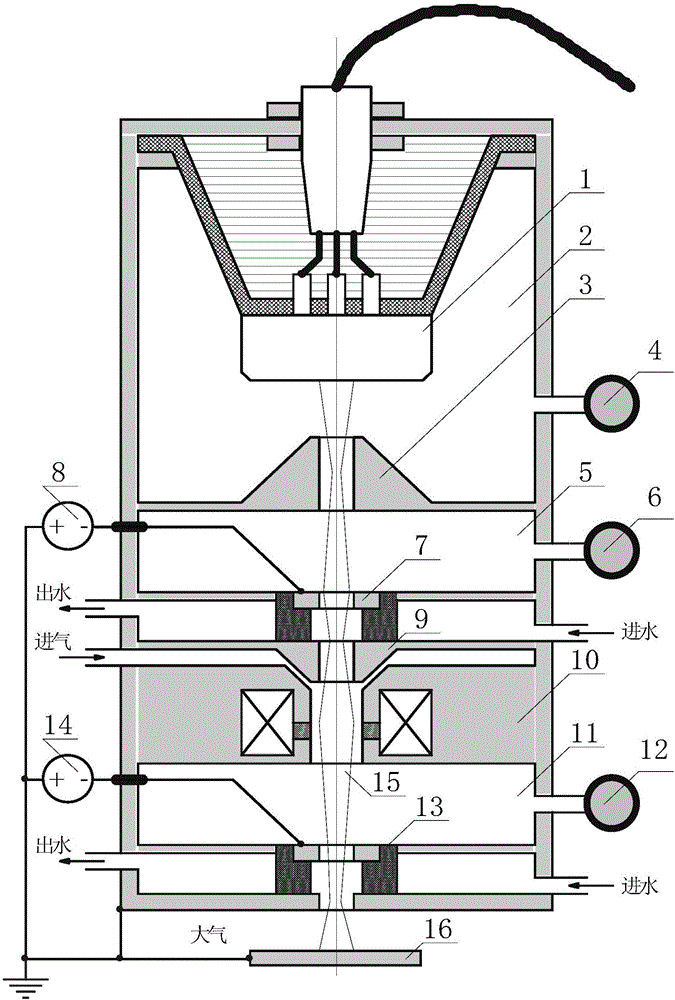

[0022] An electron gun for atmospheric electron beam processing equipment, such as figure 1 As shown, it has an axisymmetric structure as a whole, including a first plasma window 13, a first vacuum chamber 11, a focusing device 10, a pneumatic window 9, a second plasma window 7, a second vacuum chamber 5, and an anode from bottom to top. 3. The third vacuum chamber 2 and the electron beam generator 1 .

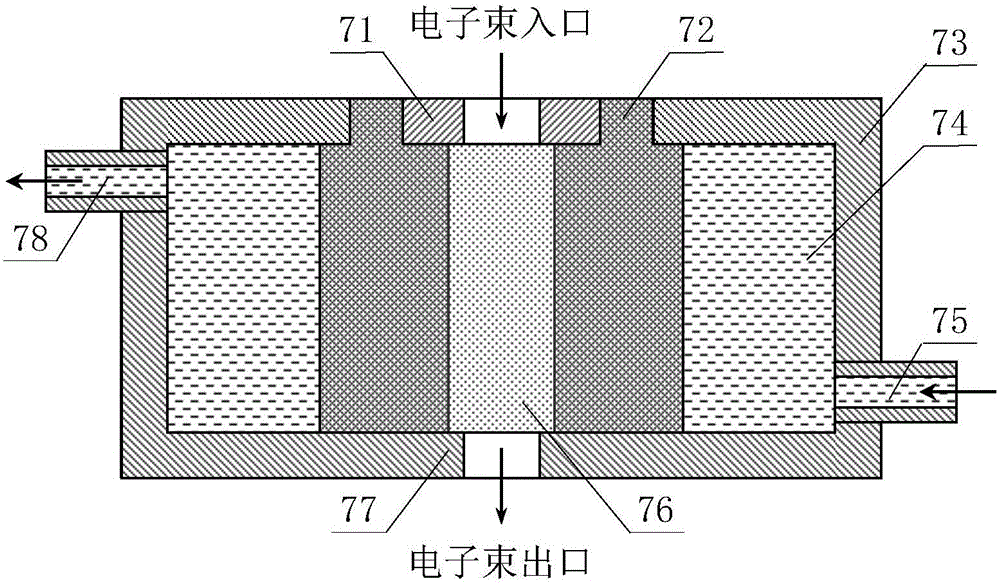

[0023] The structure of the first plasma window 13 and the second plasma window 7 is the same, as figure 2 As shown, it consists of a plasma cathode 71, a ceramic body 72, a plasma window casing 73, a cooling chamber 74, a water inlet 75, a plasma chamber 76, a plasma anode 77 and a water outlet 78. The plasma window casing 73 is a hollow airtight cavity. A ceramic body 72 is embedded in the center of the plasma window casing 73, and the ceramic body 72 is a vertically penetrating cylinder, and divides the enclosed space surrounded by the plasma window casing 73 into two in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com