Battery pack device

A packaging device and battery technology, applied in the direction of batteries, secondary batteries, battery pack components, etc., can solve the problems of increased parts procurement, low degree of commonality, and reduced assembly efficiency, and achieves simplification of the assembly process, improved commonality, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings. Wherein the same components are denoted by the same reference numerals. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "inner" and "outer ” refer to directions towards or away from the geometric center of a particular part, respectively.

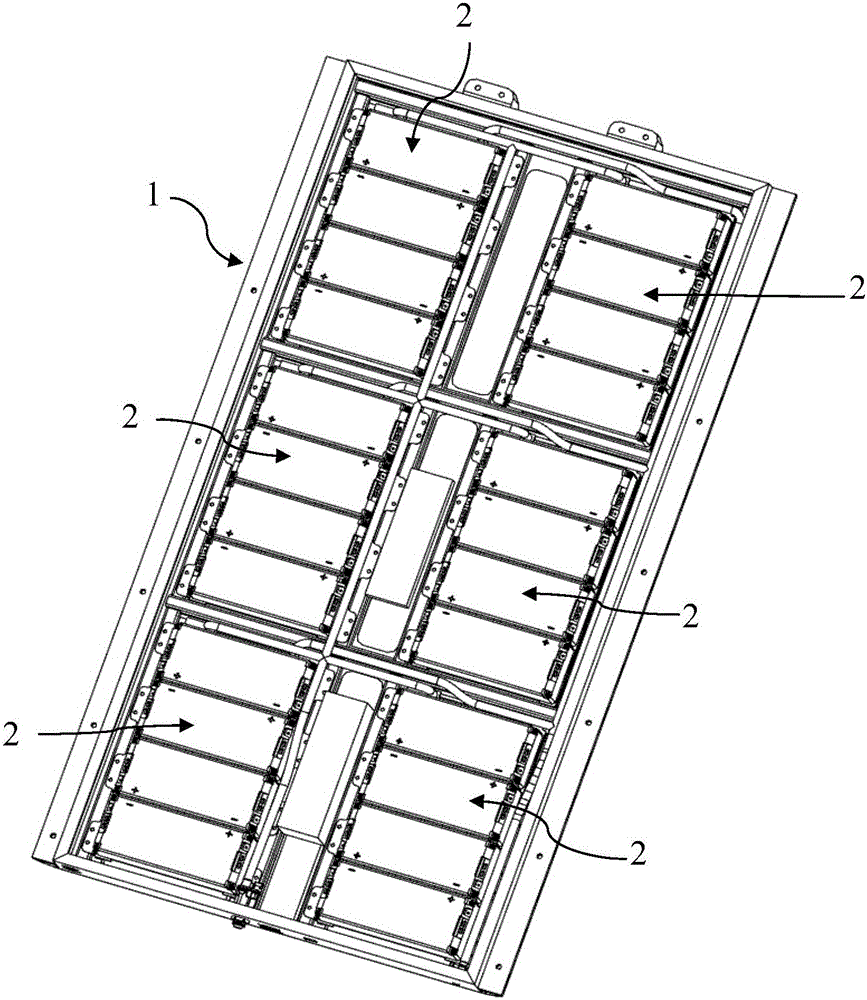

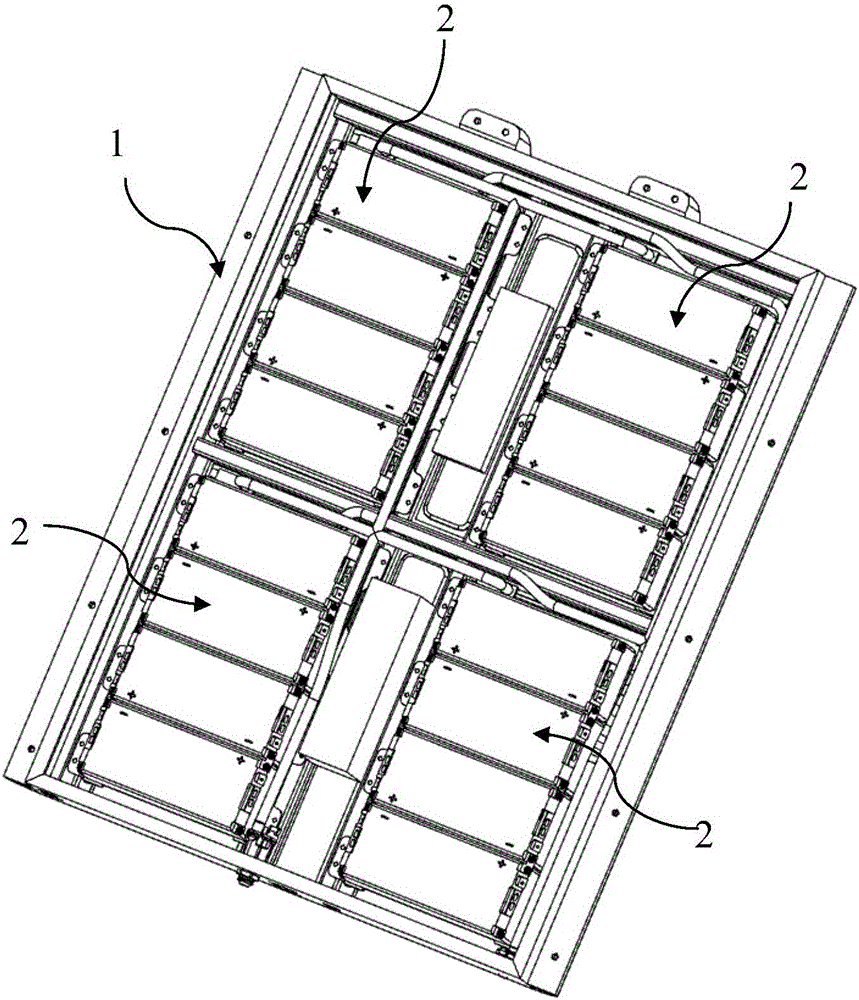

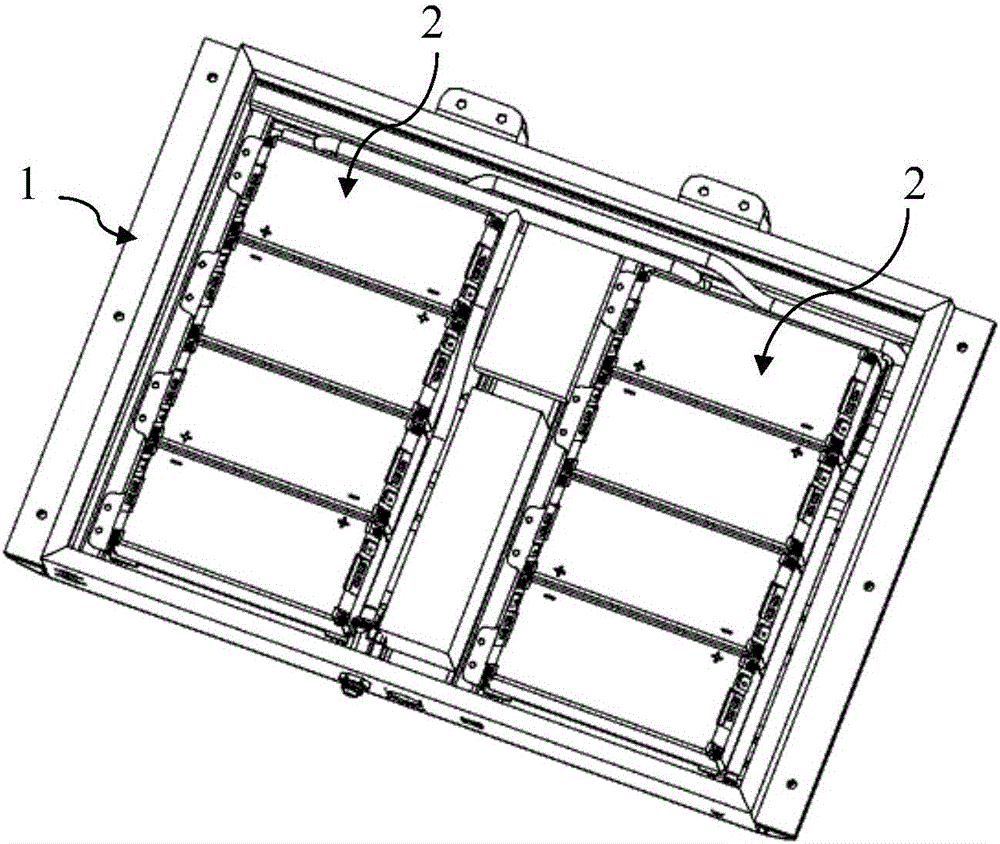

[0039] like Figure 1-8 As shown, the battery pack device provided by an embodiment of the present invention includes a length-adjustable box body 1 and at least two standard battery modules 2 sequentially connected in series.

[0040] Each standard battery module 2 is installed on the cooling plate 3 , and the cooling plate 3 is connected to the box body 1 through the mounting bracket 4 .

[0041] Standard battery modules 2 are used in the present invention, and diff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com