Low-profile conformal antenna

A technology of conformal antennas and conformal antenna arrays, applied to antennas, slot antennas, antenna components, etc., can solve the problems of large air resistance, high antenna profile, and difficulty in meeting streamlined design, and achieve low air resistance and high buff, effect with simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

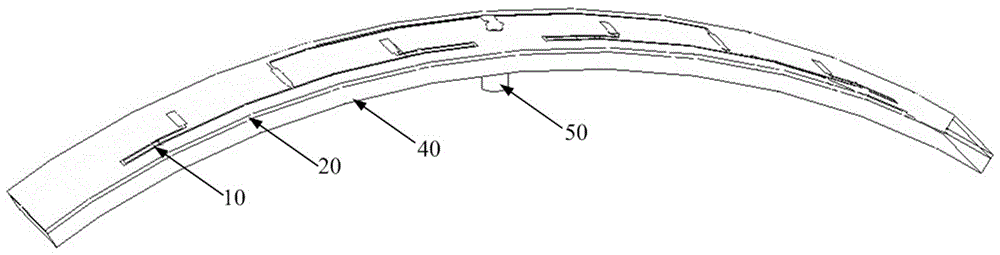

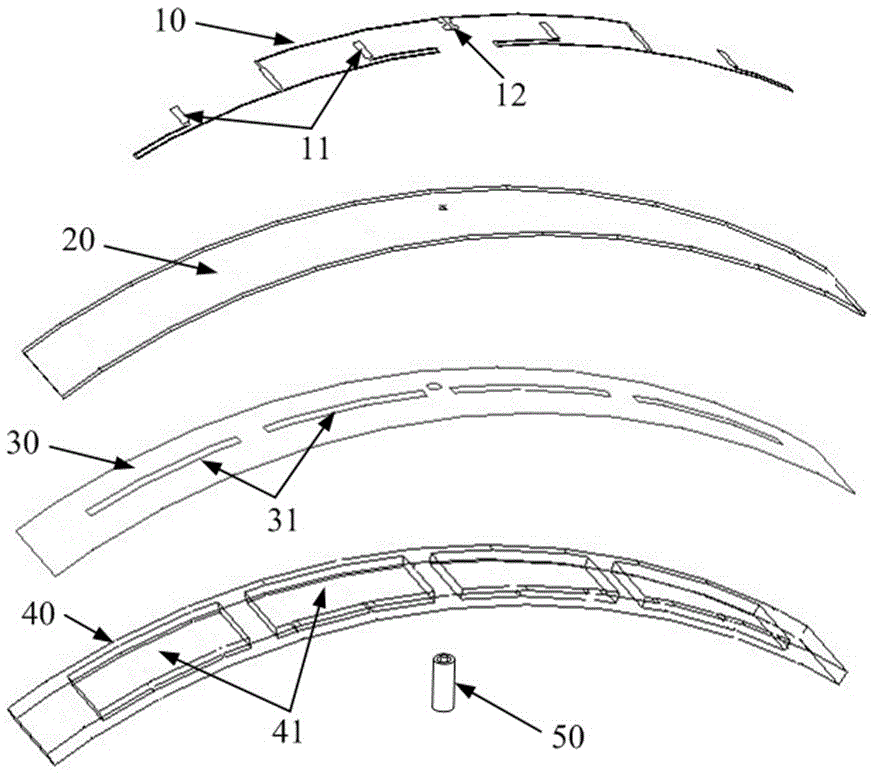

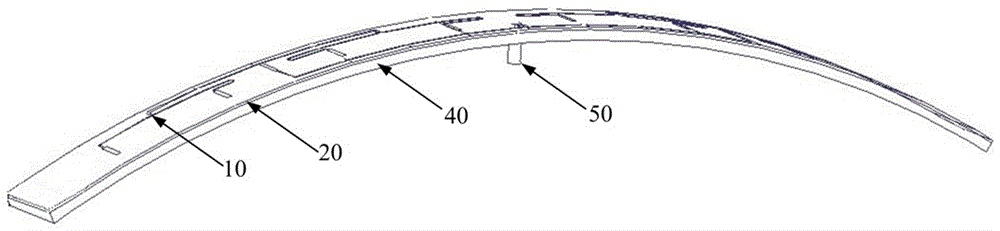

[0036] see figure 1 with figure 2 A low-profile conformal antenna includes a feed network 10, a dielectric substrate 20, a metal sheet 30, and a metal cavity-backed plate 40 that are sequentially layered and fixedly connected; the overall arc-shaped slat of the low-profile conformal antenna The profile height of the low-profile conformal antenna is 1 / 45 wavelength of the center frequency of the low-profile conformal antenna.

[0037] see figure 2 , the feed network 10 is fixed on the outer surface of the dielectric substrate 20 , and the metal sheet 30 is fixed on the inner surface of the dielectric substrate 20 .

[0038] The feed network 10 is a microstrip power divider with equal amplitude and non-equal phase, which is composed of one input terminal and four output terminals, and compensates the phase difference from the non-planar slot array to the equal phase plane;

[0039] Four radiating slits 31 are evenly distributed on the metal sheet 30 to form a slit array, an...

Embodiment 2

[0043] see image 3 with Figure 4 , the low-profile conformal antenna in Embodiment 2 is an extension of the antenna in Embodiment 1, from the original 4 radiation slots 31 to 8 radiation slots 31 . The radiating slots 31 are still in a straight slot array along the length direction of the metal sheet 30 , and the distance between adjacent radiating slots 31 is equal.

[0044] see Figure 5 , Image 6 with Figure 7 , the feed network 10 is composed of one input terminal and eight output terminals, and the corresponding radiation slots 31 are expanded into 8 slot arrays arranged in a line, and the cavities 41 on the metal back cavity board 40 are also expanded into 8 equally spaced arrays. cavity composition. Other structures are with embodiment 1.

[0045] The profile height of the antenna is 1 / 45 of the wavelength of the center frequency of the low-profile conformal antenna.

[0046] see Figure 8 with Figure 9 , the bandwidth of the port standing wave of the ante...

Embodiment 3

[0048] see Figure 10 , this embodiment is extended from Embodiment 2 to form a one-dimensional phase-swept array. The antenna array is composed of 16 antennas in Embodiment 2. The adjacent metal cavity-backed plates 40 and the dielectric substrate 20 are seamlessly connected, and the coaxial feed connector 50 of each low-profile conformal antenna is located at Same side of the low-profile conformal antenna array. The section height of the low-profile conformal antenna array is 1 / 45 of the center frequency wavelength of the low-profile conformal antenna, and can realize one-dimensional phase scanning.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com