Maglev centrifugal atomization electronic cigarette

A centrifugal atomization and e-cigarette technology, applied in the field of e-cigarettes, can solve problems such as smoking odor or aroma changes, heating elements dry-burning, affecting the quality of smoking, etc., to overcome its own gravity, reduce axial resistance, reduce The effect of small current consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

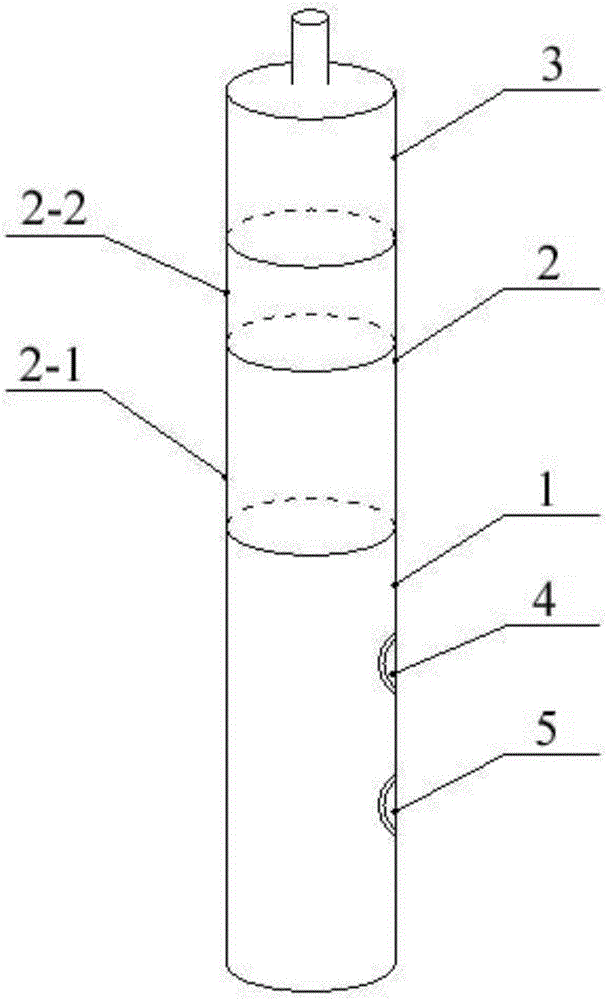

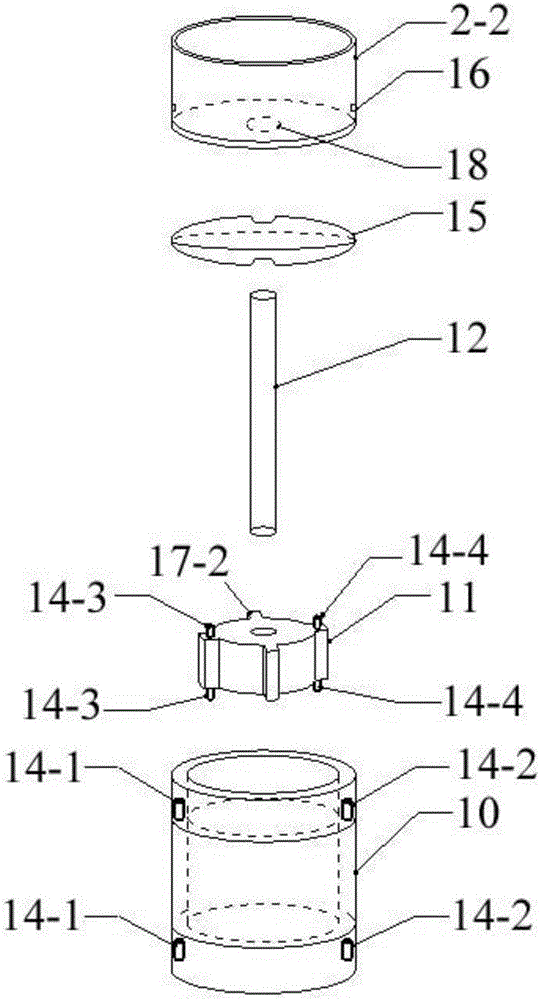

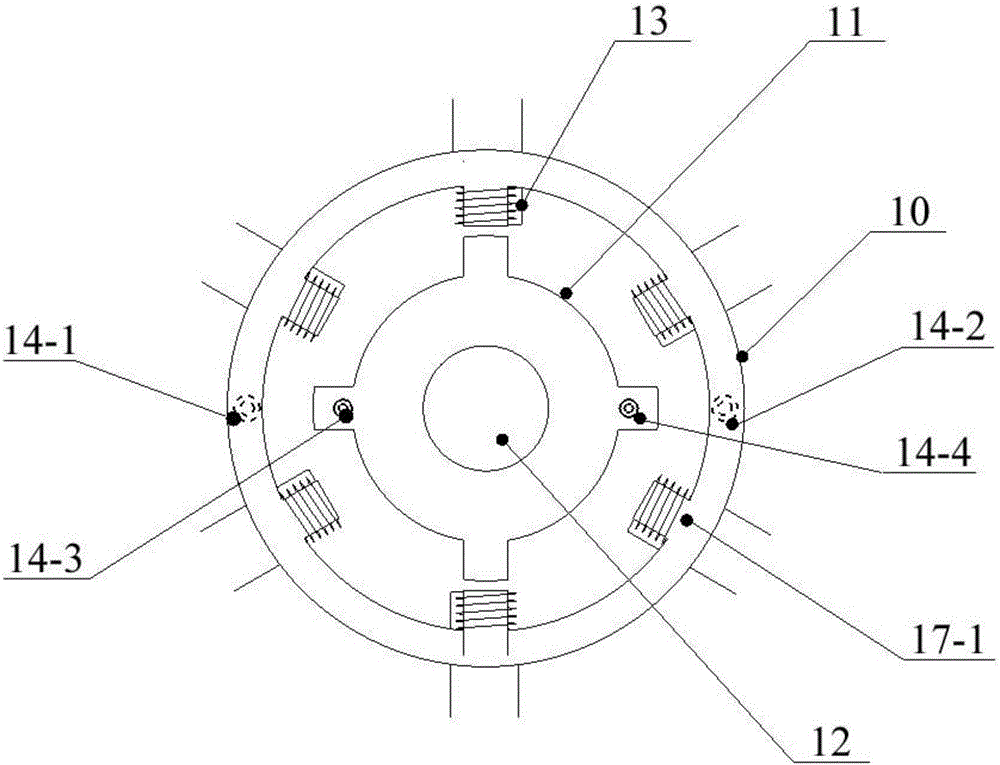

[0040] Assembly of the electronic cigarette: first assemble the atomizer, insert the rotating shaft extending outside the switched reluctance motor part into the atomization chamber through the center hole 18 at the bottom of the atomization chamber, and connect the bottom end of the atomization chamber to the top of the switched reluctance motor part The installation is fixed. Set the turntable on the rotating shaft in the atomization chamber. Then, cover the nozzle end and fix it with the top of the atomization chamber. Finally, connect the main unit to the end of the atomizer.

[0041] Use of e-cigarettes: Add the e-liquid dropwise on the turntable and install the suction nozzle. Start the power switch and work switch on the host, the coil winding on the stator inside the atomizer is energized and excited, the levitation force winding in it generates radial levitation force, and the electromagnetic force winding generates electromagnetic rotational force, making the rotor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com