Powder recovery post-processor

A post-processing machine and powder technology, which is applied to the separation of dispersed particles, chemical instruments and methods, combined devices, etc., can solve the problems of increased cost of a single machine, limited use of post-processing machines, and no expansion functions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Some typical embodiments embodying the features and advantages of the present invention will be described in detail in the description in the following paragraphs. It should be understood that the present invention can have various changes in different aspects without departing from the scope of the present invention, and the descriptions and illustrations therein are used as illustrations in nature rather than limiting the present invention .

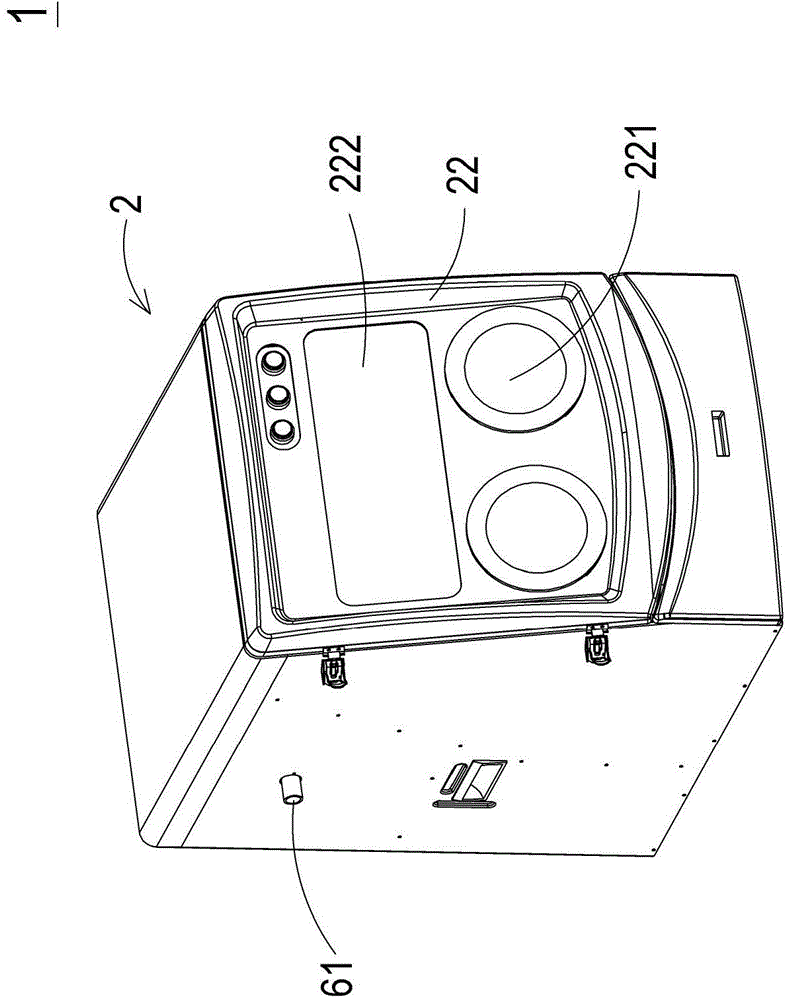

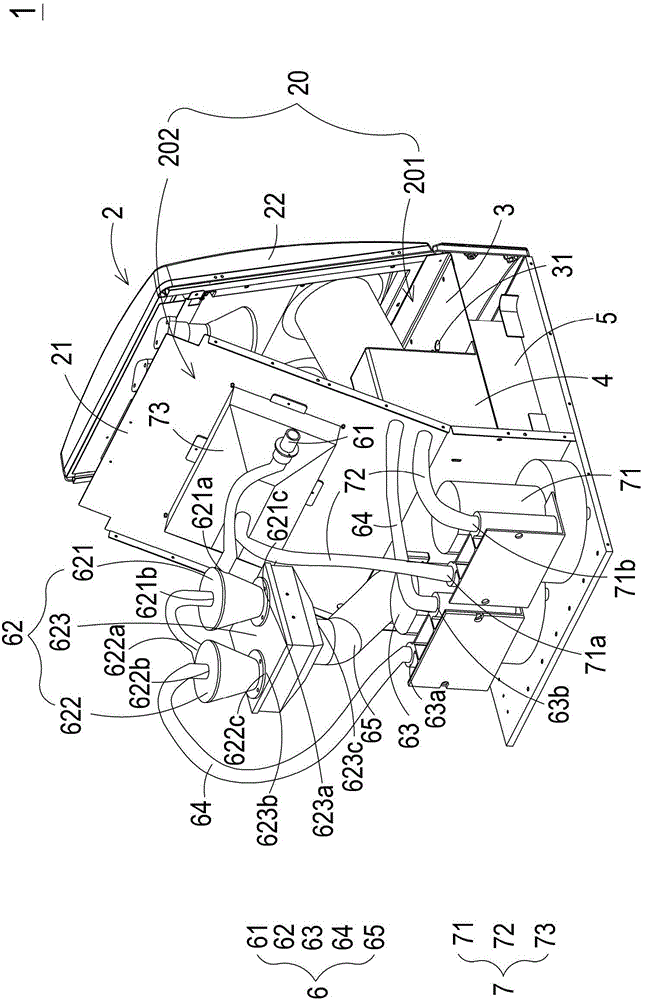

[0048] Please also see figure 1 and figure 2 , which are respectively the structural schematic diagram of the powder recovery post-processing machine of the preferred embodiment of the present invention and figure 1 A schematic diagram of the internal structure of the powder recovery post-processing machine shown. As shown in the figure, the powder recovery post-processing machine 1 of the present invention is suitable for a three-dimensional molding device (not shown), and is used to move the three-dimensional molding (not ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com