Wall surface polishing device for building decoration engineering

A technology for building decoration engineering and grinding boards, which is applied in the direction of grinding drive devices, grinding/polishing safety devices, machine tools suitable for grinding workpiece planes, etc., and can solve the problems of affecting the grinding effect of the wall surface and grinding the dead corner of the wall surface, etc. , to achieve the effect of saving resources and improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following is attached Figure 1-7 The application is described in further detail.

[0040] The embodiment of the present application discloses a wall polishing device for building decoration engineering.

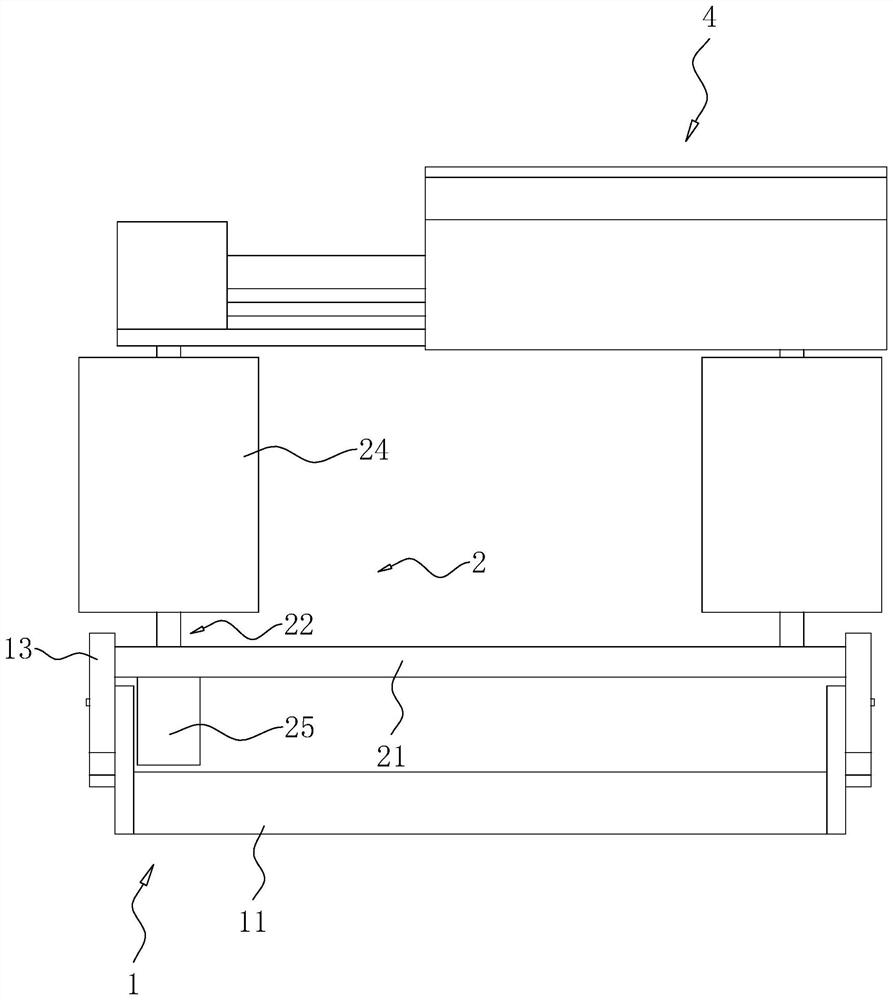

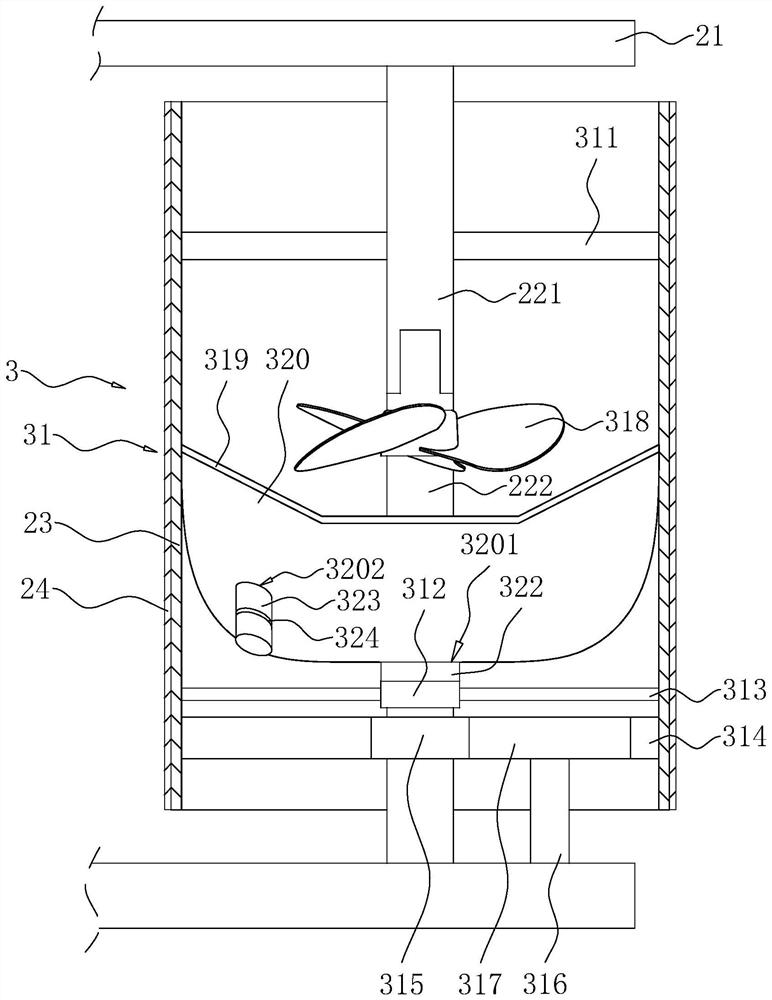

[0041] refer to figure 1 and figure 2 , a wall polishing device for building decoration engineering includes a switching mechanism 1, a first polishing mechanism 2, a second polishing mechanism 4 and a dust removal mechanism 3, the first polishing mechanism 2 is used to polish the wall surface, and the second polishing mechanism 4 The switch mechanism 1 is used to switch between the first grinder mechanism 2 and the second grinder mechanism 4 , and the dust removal mechanism 3 is used to absorb the dust generated by the first grinder mechanism 2 .

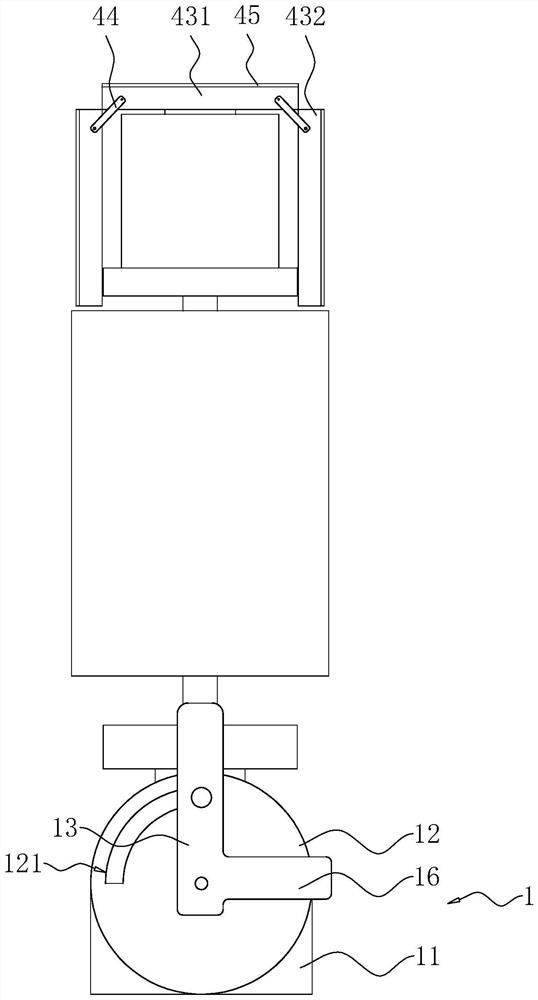

[0042] refer to image 3 and Figure 4 , the switching mechanism 1 includes a support base 11, the length direction of the support base 11 is horizontally arranged, and both ends of the support base 11 in the len...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com