Preparation method of high-efficiency desorption air separation molecular sieve

A molecular sieve and desorption technology, applied in the field of molecular sieve, can solve problems such as difficulty in meeting technical requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

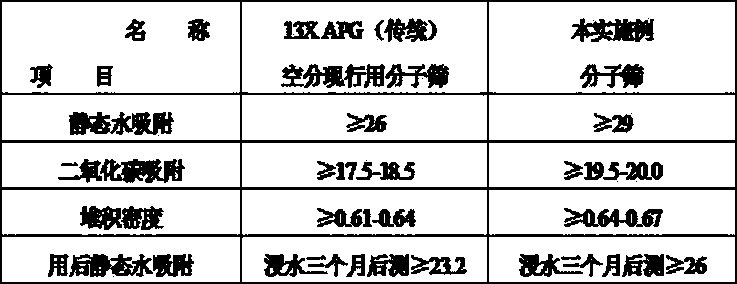

Image

Examples

Embodiment 1

[0018] Follow the steps below to prepare highly efficient desorption air separation molecular sieves:

[0019] 1) Molecular sieve raw powder leaching: add artificially synthesized zeolite powder into a sodium carbonate solution with a concentration of 35-45% by mass, undergo hydrothermal crystallization at 150°C for 200 minutes, and obtain molecular sieve raw powder;

[0020] 2) Dry the molecular sieve raw powder prepared in step 1) at 180°C until the water content is below 20% by weight, mix it with kaolin, attapulgite, foreign crucible, and bayberry extract, and then grind it to 325 mesh After the above, carry out granulation or extrusion molding to obtain a molecular sieve body; wherein the weight percentage of each raw material component is: molecular sieve raw powder 40kg; kaolin 10kg; attapulgite 10kg; foreign crucible 10kg; bayberry extract 30kg.

[0021] 3) Dry the molecular sieve body prepared in step 2) and place it in a rotary furnace for 80-90 minutes under the pro...

Embodiment 2

[0023] Follow the steps below to prepare highly efficient desorption air separation molecular sieves:

[0024] 1) Molecular sieve raw powder leaching: add zeolite powder into a sodium silicate solution with a concentration of 35% by mass, undergo hydrothermal crystallization at 150°C for 200 minutes, and obtain molecular sieve raw powder;

[0025] 2) Dry the molecular sieve raw powder prepared in step 1) at 160°C until the water content is 18% by weight, mix it with kaolin, attapulgite, bayberry extract, and sodium carboxymethyl cellulose, and then grind After reaching 325 mesh or more, carry out granulation or extrusion molding to obtain a molecular sieve green body; wherein the weight percentage of each raw material component is: molecular sieve raw powder 40kg; kaolin 10kg; attapulgite 20kg; bayberry extract 20kg; carboxymethyl cellulose Sodium 10kg.

[0026] 3) Dry the molecular sieve body prepared in step 2) and place it in a rotary furnace for 90 minutes under the prote...

Embodiment 3

[0028] Follow the steps below to prepare highly efficient desorption air separation molecular sieves:

[0029] 1) Molecular sieve raw powder leaching: add zeolite powder into a sodium bicarbonate solution with a concentration of 45% by mass, undergo hydrothermal crystallization at 160°C for 160 minutes, and obtain molecular sieve raw powder;

[0030] 2) Dry the molecular sieve raw powder prepared in step 1) at 160°C until the water content is less than 20% by weight, mix it with attapulgite and bayberry extract, and then grind to 325 mesh or more before granulating Or extrusion molding to obtain a molecular sieve body; wherein the weight percentage of each raw material component is: molecular sieve raw powder 40kg; attapulgite 30kg; red bayberry extract 30kg.

[0031] 3) Dry the molecular sieve body prepared in step 2) and place it in a rotary furnace for 90 minutes under the protection of nitrogen to obtain an air separation molecular sieve with high-efficiency desorption. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com