Full-automatic rib press

A bead press machine and fully automatic technology, which is applied to engine components, mechanical equipment, forging/pressing/hammer devices, etc., can solve the problems of high pressure coefficient of bead press devices, affecting the processing efficiency of workpieces, and easily crushing workers' fingers, etc. Achieve a high degree of automation, reduce the number of manual feeding, and reduce the labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

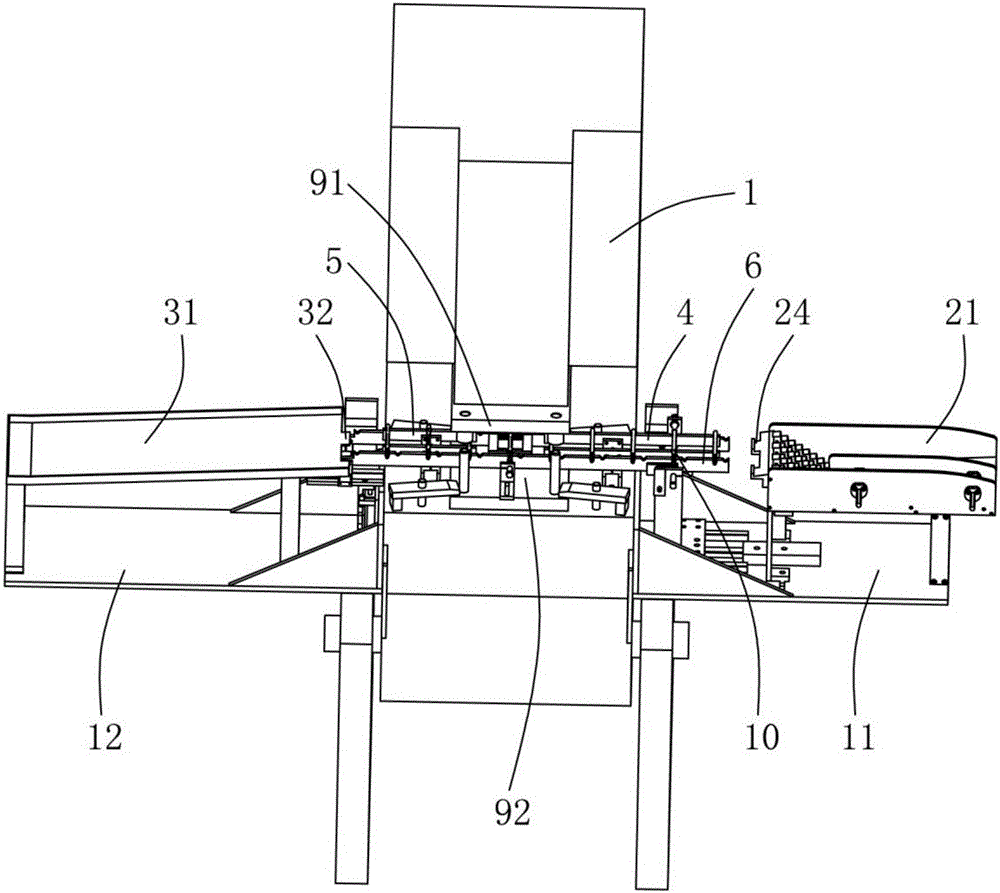

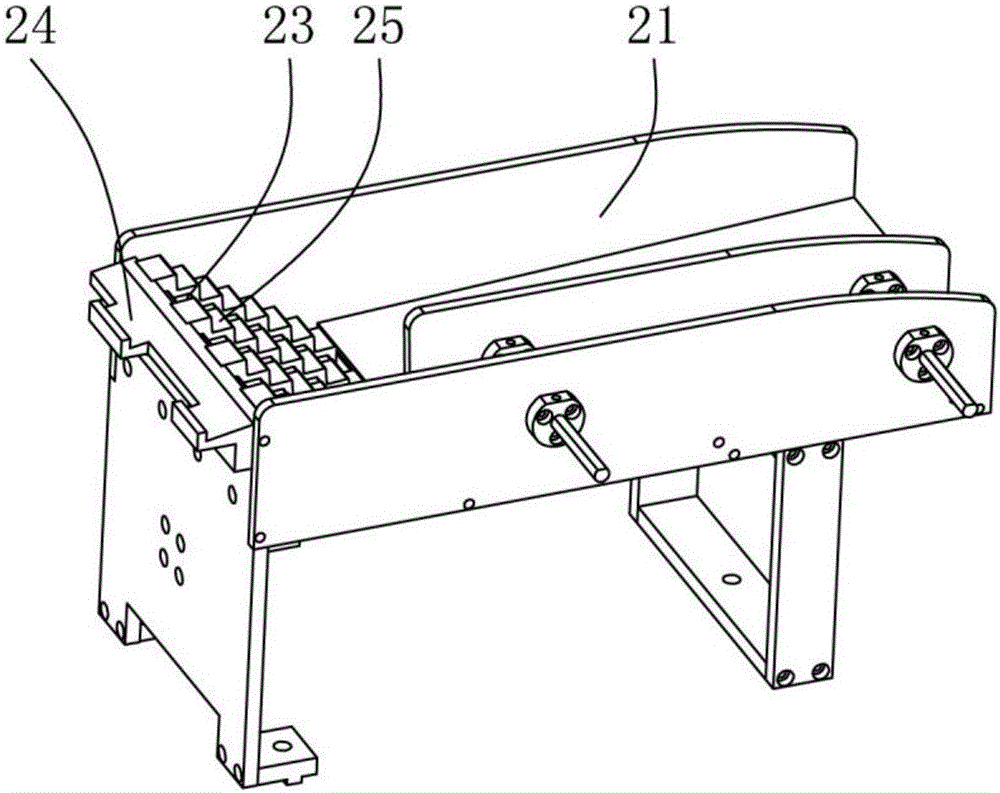

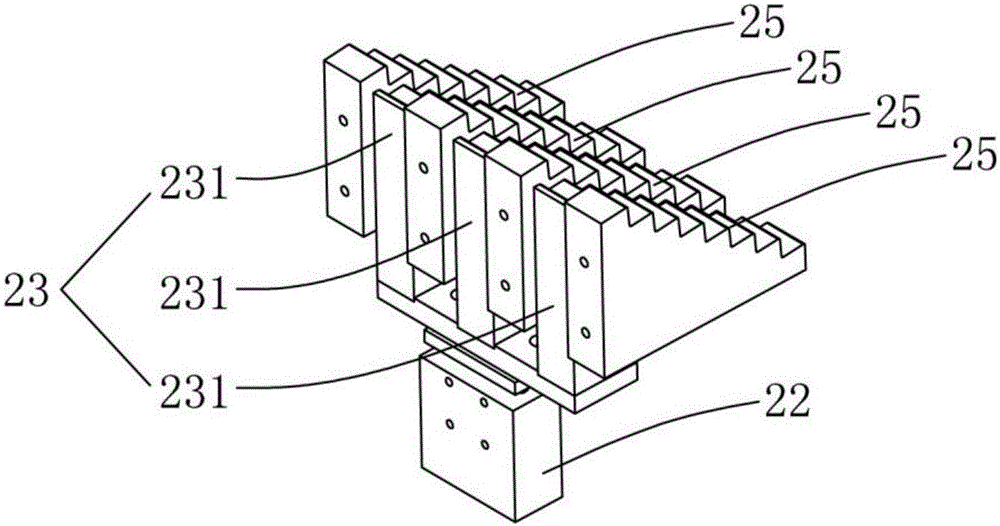

[0032] Such as Figure 1 to Figure 8 A fully automatic beading machine shown includes a punching machine 1, a feeding mechanism, a blanking mechanism, a first fixed beam assembly 4, a second fixed beam assembly 5, and a moving beam assembly 6. The feeding mechanism and the blanking mechanism are respectively Located on both sides of punch press 1. Feeding mechanism comprises feeding box 21 and material pushing cylinder 22, and pushing material cylinder 22 is arranged on the bottom of feeding box 21, is provided with jacking block 23 in feeding box 21, and the output end of pushing material cylinder 22 and jacking block 23 transmission connection, the outer edge of the discharge port of the upper material box 21 is provided with a first material holding assembly 24; when the pushing cylinder 22 moves each time, the ejector block 23 correspondingly sends a workpiece 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com