Pipe expander

A tube expander and expander technology, which is applied in the field of tube expanders, can solve the problems of complex structure, inconvenient to carry, and heavy weight, and achieve the effects of reasonable structural design, convenient manual operation, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

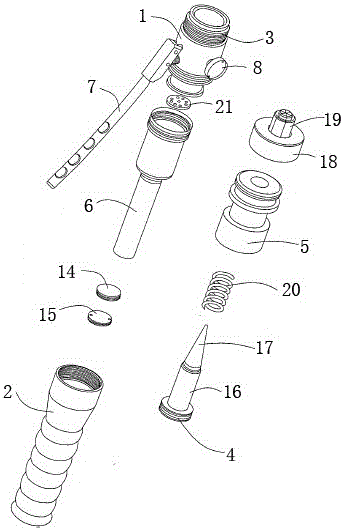

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

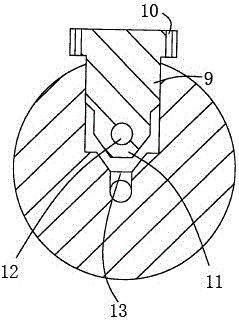

[0014] Such as Figure 1-2 As shown, a tube expander of the present invention includes a piston cylinder 4 comprising a hydraulic pump 1, a handle 2, and a built-in piston 3. The handle 2 and the piston cylinder 4 are respectively arranged at both ends of the hydraulic pump 1, and the opening of the piston cylinder 4 A cylinder head 5 is arranged at the cylinder head 5, and an expansion head is arranged on the cylinder head 5. The handle 2 is connected with the oil pressure pump 1 through the oil storage pipe 6. The outer wall of the oil pressure pump 1 is provided with a hand pressure handle 2, and the oil pressure pump 1 is close to the hand pressure handle 7. An oil return component 8 is arranged on the side; the oil return component 8 includes an oil return rod 9, a rotating handle 10 arranged at one end of the oil return rod 9 and a tapered part 11 arranged at the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap