Motor vehicle lamp LED light source positioning method based on machine vision

A technology of LED light source and machine vision, which is applied in the direction of metal processing equipment, milling machine equipment, milling machine, etc., can solve the problems of the whole light shape change, the position deviation of LED light source, the influence of the light distribution of the car light, etc., so as to improve the effect and improve the light distribution performance and improve assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

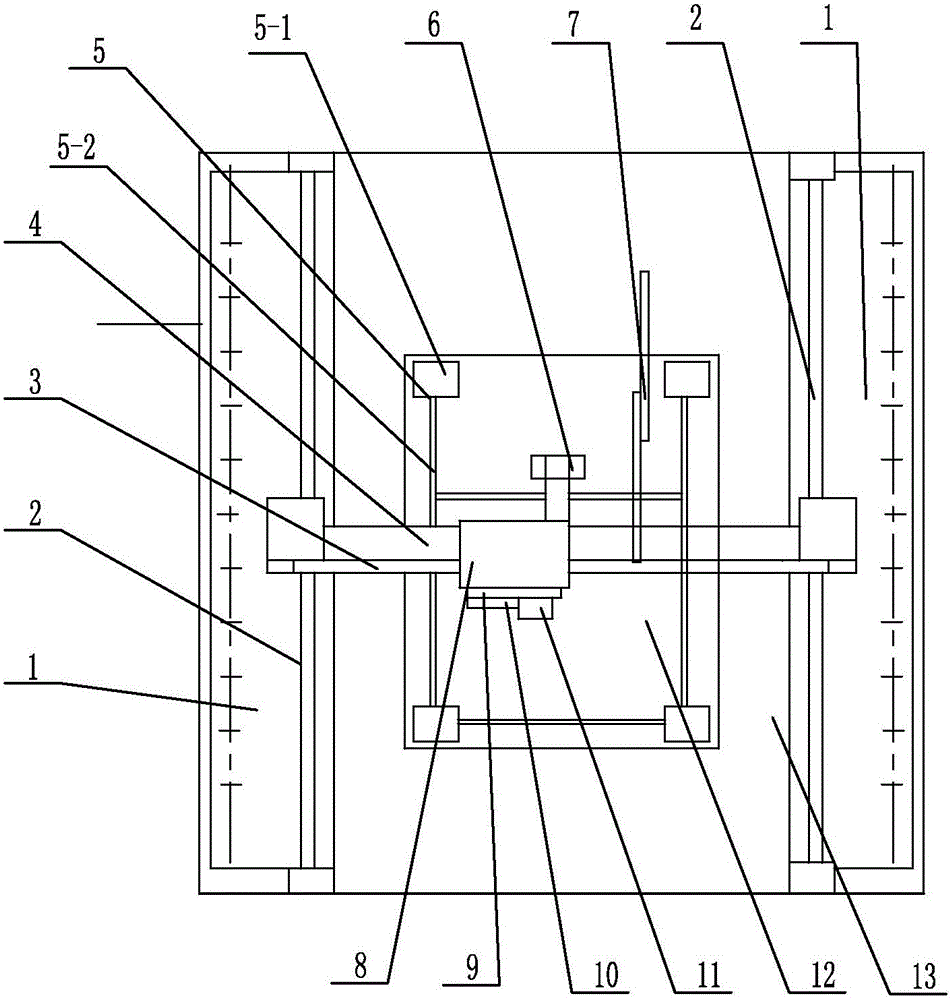

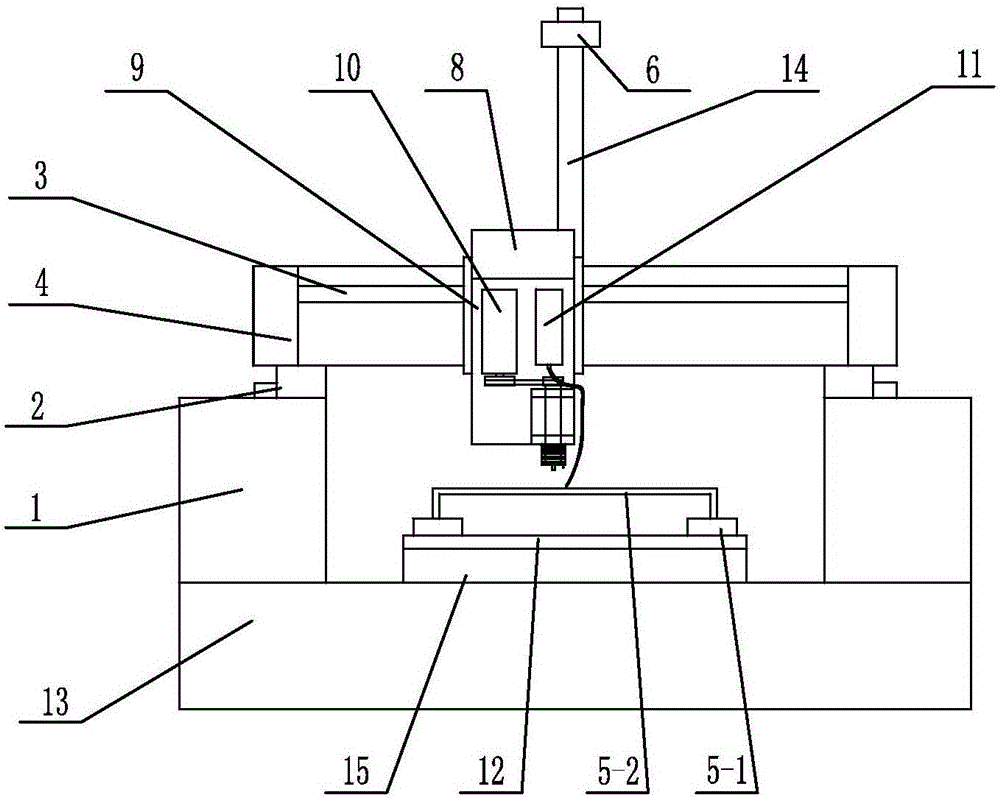

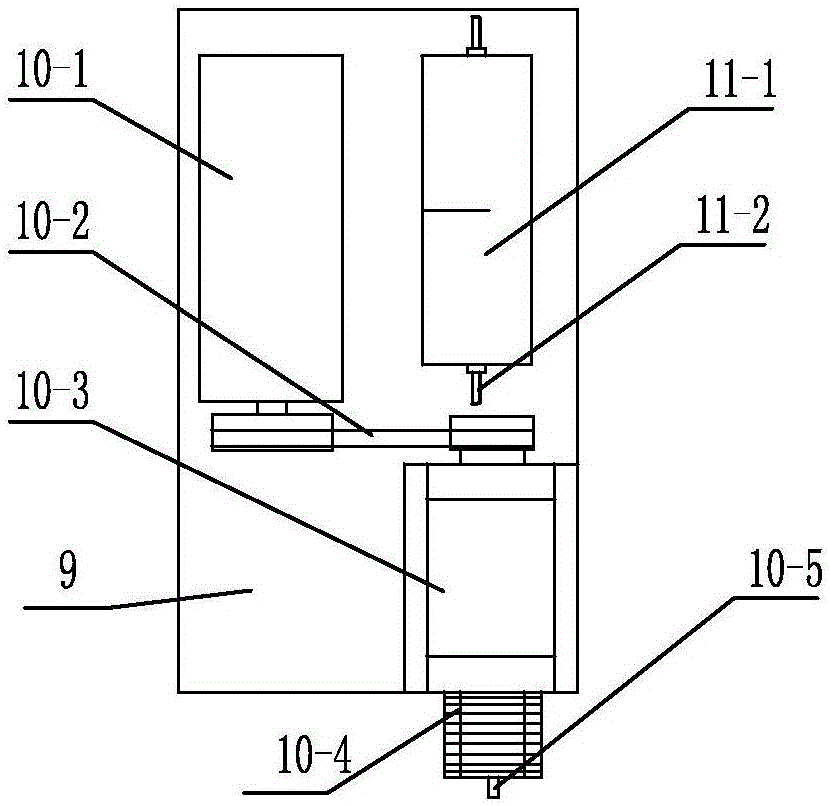

[0021] See Figure 1~3 Shown, the present invention is based on the machine vision LED light source positioning method of motor vehicle lights, according to the following steps.

[0022] (1) Transport the circuit board 12 fixed with the LED light source to the workbench 13 of the punching station, press and position it on the workbench 13 by the pressing block 5-1, so that the circuit board 12 is processed on the workbench 13 Can not move. The compression mechanism 5 of the present invention is installed on the workbench 13, and the briquetting block 5-1 of the compression mechanism is arranged around, and the briquetting block 5-1 is connected with the frame 5-2, and the frame 5-2 is connected with the cylinder. The frame 5-2 is driven to make multiple pressure blocks 5-1 act simultaneously, which is convenient for crimping the circuit board 12 on the workbench 13 or releasing the circuit board 12. See figure 2 As shown, the present invention can be provided with backing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com