Demounting and mounting device of valve lock clamp

A technology of valve lock clamp and cylinder head, which is applied in the direction of hand-held tools and manufacturing tools, which can solve the problem of poor positioning accuracy of disassembly and assembly devices, inability to meet the disassembly and assembly requirements of large quantities, high strength and high efficiency, and low work efficiency of personnel and other problems, to achieve the effect of high disassembly and assembly efficiency, reasonable structural design and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0031] The present invention will be described in detail below with reference to the accompanying drawings and examples.

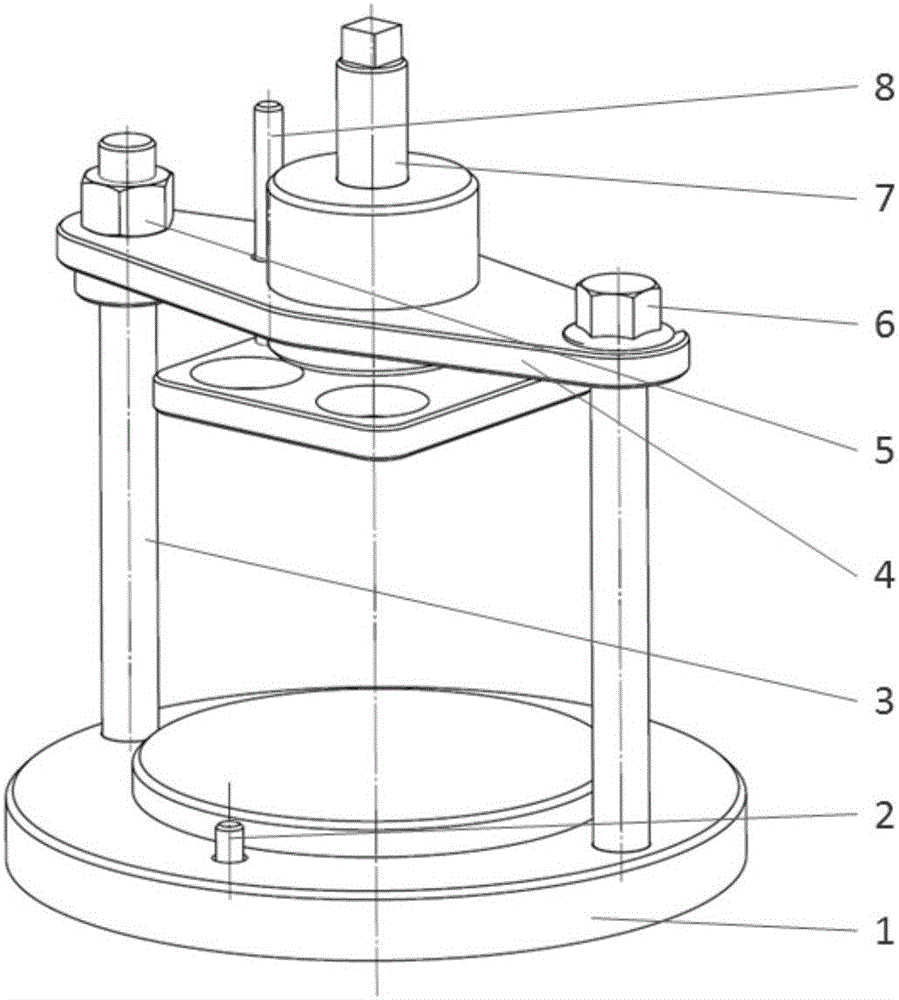

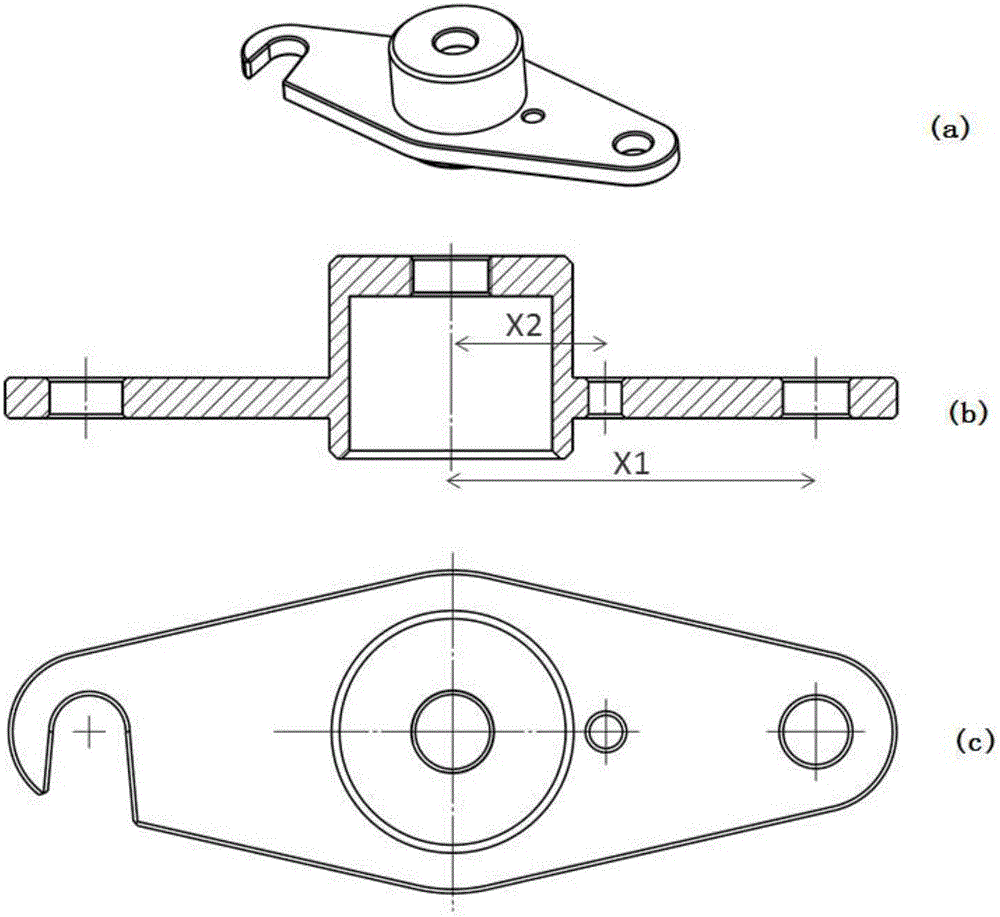

[0032] A valve lock clip disassembly device, such as Figures 1 to 3 As shown, it includes a base 1, a first positioning stud 3, a fixed pressing plate 4, a pressing bolt 6, a rotating pressing plate 7 and a second positioning stud 8,

[0033] The base 1 is provided with a positioning structure for disassembling the cylinder head with a positioning belt; the two ends of the fixed pressure plate 4 are respectively fixed on the base 1 through the first positioning stud 3 and the compression bolt 6;

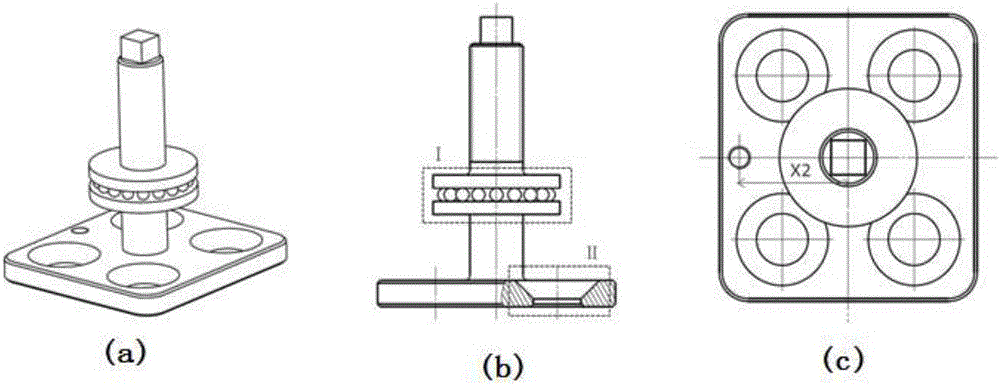

[0034] The rotating platen 7 includes an upper threaded rod structure, a middle load-bearing structure and a lower bottom plate structure connected sequentially from top to bottom;

[0035] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com