A fully automatic vacuum casting method for multiple irregular molds

A technology of vacuum pouring and automatic pouring, which is applied in the field of vacuum pouring of molds, can solve the problems that positioning and pouring methods are no longer applicable, and automatic pouring cannot be realized, so as to save production costs and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with specific embodiments.

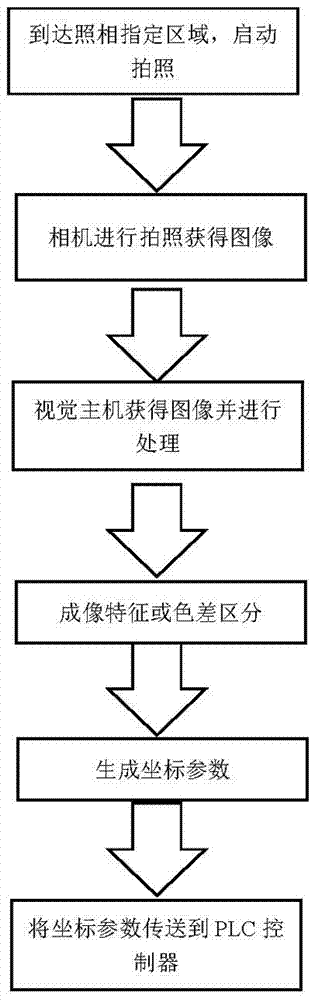

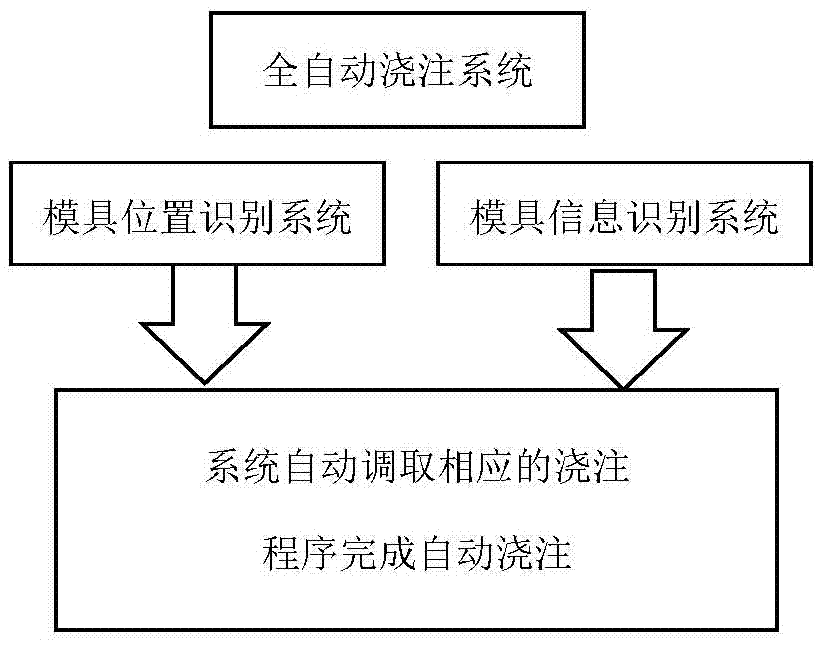

[0028] A fully automatic vacuum pouring method for multiple irregular molds, including four steps of identification and positioning of mold gates, automatic positioning of nozzles, identification of mold information and automatic pouring.

[0029] (1) Identification and positioning of the mold gate

[0030] (1) Camera imaging technology is used to identify the imaging position of the mold before pouring. Place single or multiple molds on the tray at random, place the tray in the designated area of the camera through manual or transmission mechanism to take pictures to obtain images of the tray and mold, and send the image to the visual host

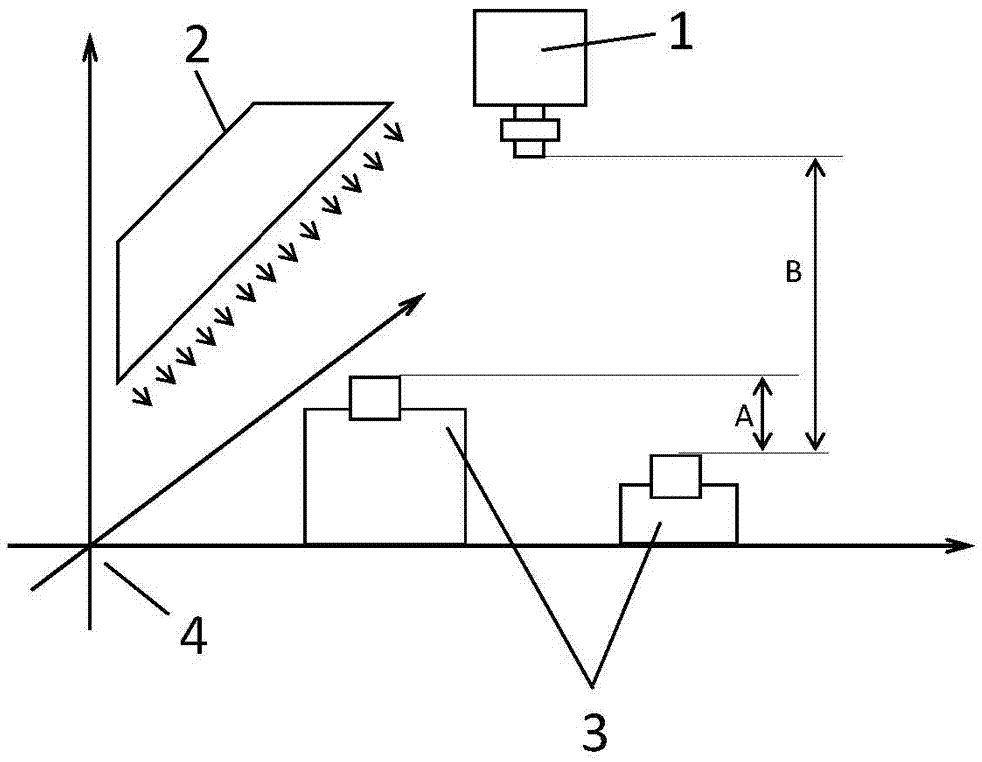

[0031] The lens used by the camera can be adjusted according to the required imaging drop to ensure a certain height drop A (such as 1000mm, such as figure 2 Shown) within the scope of the mold sprue can be clearly imaged, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com