Method for automatic pouring of thin sheet bar continuous casting machine

A thin slab continuous casting and automatic casting technology, applied in the field of all-endless thin slab continuous casting and rolling, can solve the problems of high accident rate of manual casting and unstable casting quality, so as to avoid breakout or continuous rolling. Terminal phenomenon, maintaining liquid level stability, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

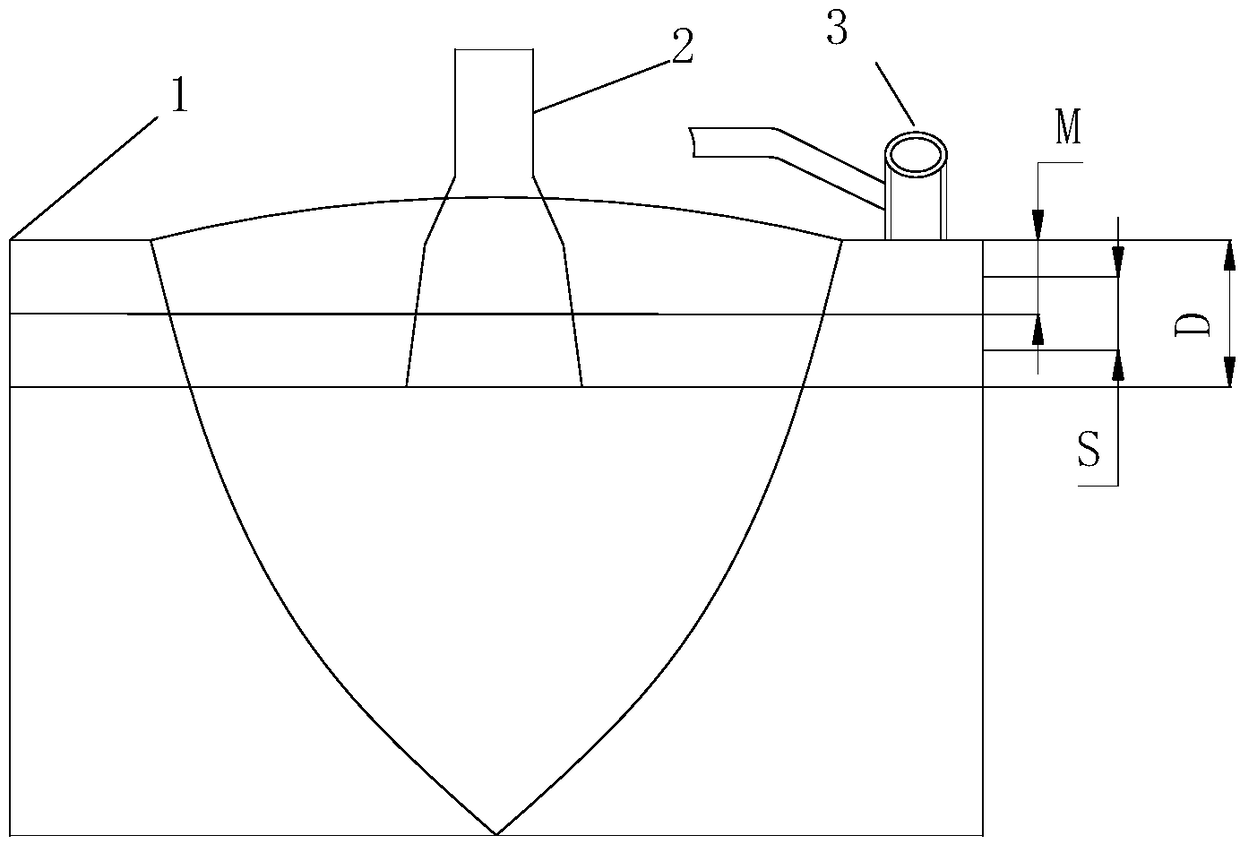

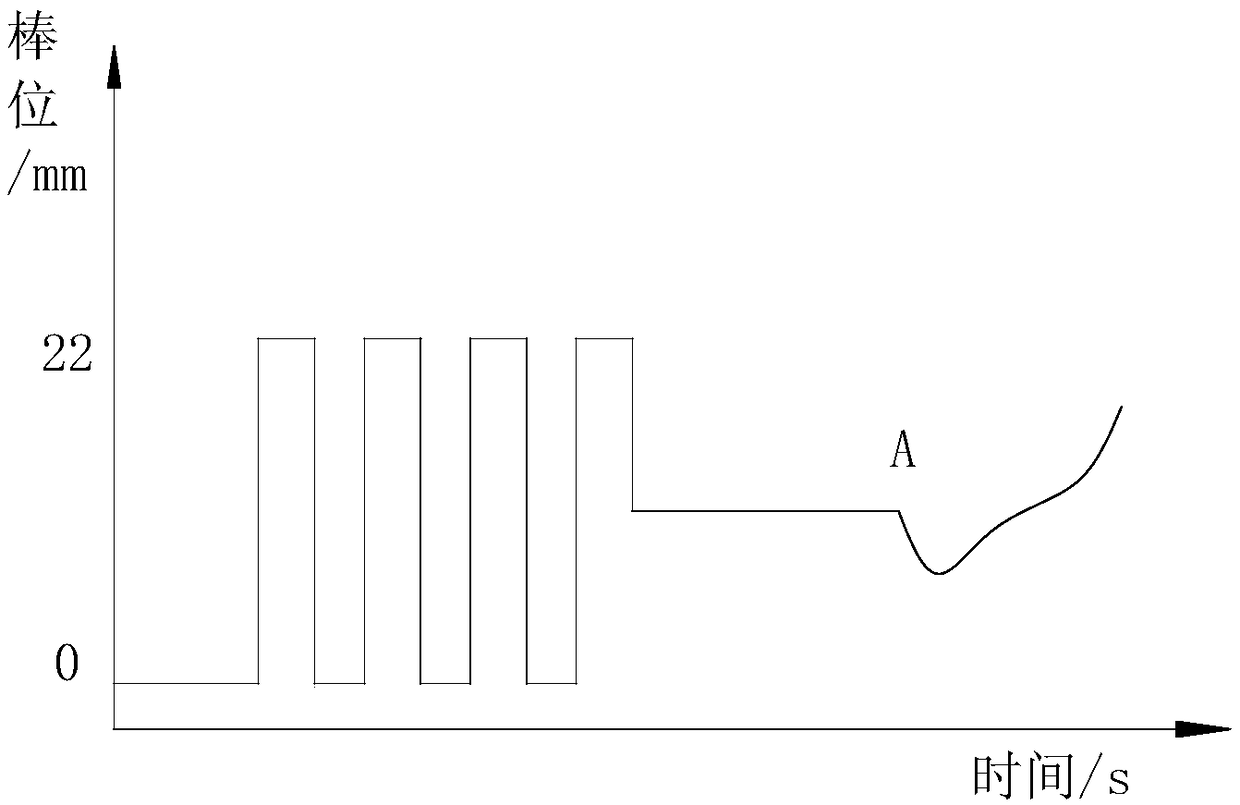

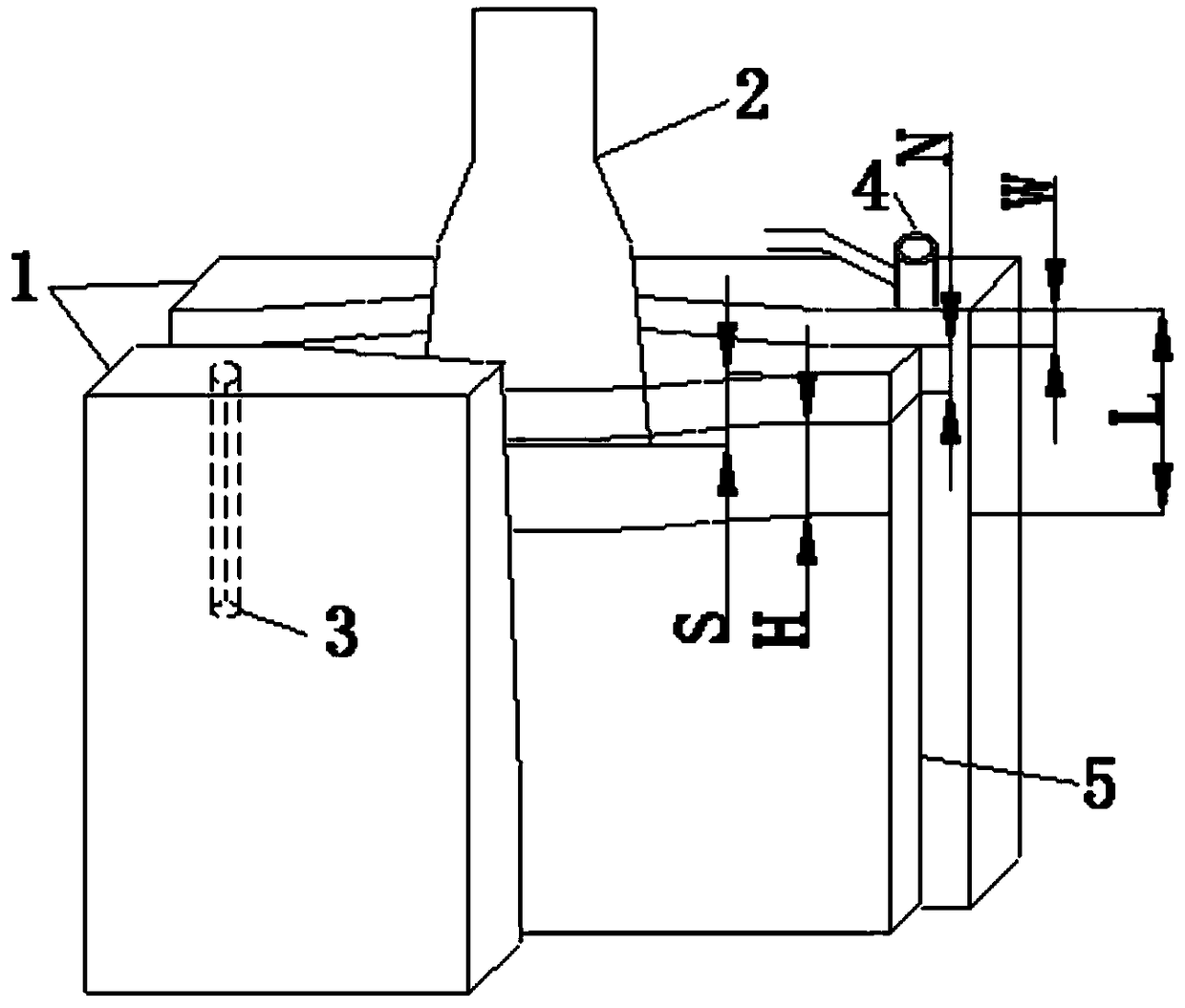

[0040] The production section is 1500×100mm 2 The thin slab adopts the following technical solutions:

[0041] Such as Figure 5 As shown, the method for automatic pouring of thin slab continuous casting machine is as follows:

[0042] (1) Turn on the roaster, the roaster is right Image 6 The shown tundish 6 is baked, the baking time is 5.5h, and the temperature of the tundish 6 is 1280℃; when the baking is finished, lift the roaster, and add to the inside of the tundish 6 through the lid hole 7 of the tundish The amount of the lower covering agent is 200kg, so that the covering agent is located between the barrier 8 and the barrier 9; then two argon pipes 11 are set at the pouring hole 10, and the flow rate of argon is controlled to 2250L / min, so that the argon can pass through The argon pipe enters the interior of the tundish 6, which is convenient for gas washing of molten steel;

[0043] (2) After the centering of the tundish car is completed, the ladle slide plate is opened, a...

Embodiment 2

[0050] The production section is 1175×100mm 2 The thin slab adopts the following technical solutions:

[0051] Such as Figure 5 As shown, the method for automatic pouring of thin slab continuous casting machine is as follows:

[0052] (1) Turn on the roaster, the roaster is right Image 6 The shown tundish 6 is baked, the baking time is 5.5h, and the temperature of the tundish 6 is 1280°C; when the baking is finished, lift the roaster, and add to the inside of the tundish 6 through the cover hole 7 of the tundish The amount of the lower layer of covering agent is 200kg, so that the covering agent is located between the barrier 8 and the barrier 9; then two argon pipes 11 are set at the pouring hole 10, and the flow rate of argon is controlled to 2000L / min to allow argon to pass The argon pipe enters the interior of the tundish 6, which is convenient for gas washing of molten steel;

[0053] (2) After the centering of the tundish car is completed, the ladle slide plate is turned on,...

Embodiment 3

[0060] The production section is 1219×100mm 2 The thin slab adopts the following technical solutions:

[0061] Such as Figure 5 As shown, the method for automatic pouring of thin slab continuous casting machine is as follows:

[0062] (1) Turn on the roaster, the roaster is right Image 6 The shown tundish 6 is baked, the baking time is 5.5h, and the temperature of the tundish 6 is 1280°C; when the baking is finished, lift the roaster, and add to the inside of the tundish 6 through the cover hole 7 of the tundish The amount of the lower covering agent is 200kg, so that the covering agent is located between the dam 8 and the dam 9; then two argon pipes 11 are set at the pouring hole 10, and the flow rate of argon is controlled to 2500L / min, so that the argon can pass through The argon pipe enters the inside of the tundish to facilitate the gas washing of molten steel;

[0063] (2) After the tundish car is centered, the ladle slide plate is turned on, and the pouring starts, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com