Full-automatic resin lens mold assembly and pouring system

A resin lens and pouring system technology, which is applied to household appliances, other household appliances, optical components, etc., can solve the problem that the tape clamping machine and the resin lens casting machine cannot be processed continuously and automatically, so as to reduce the labor intensity of workers and prevent colloids. The effect of overflowing and preventing air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

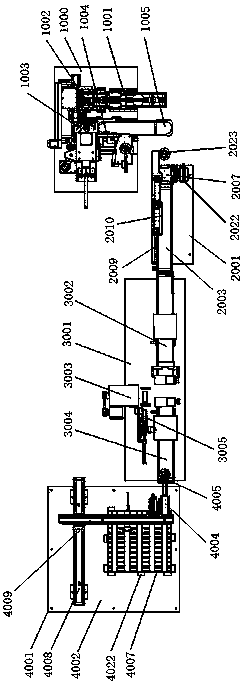

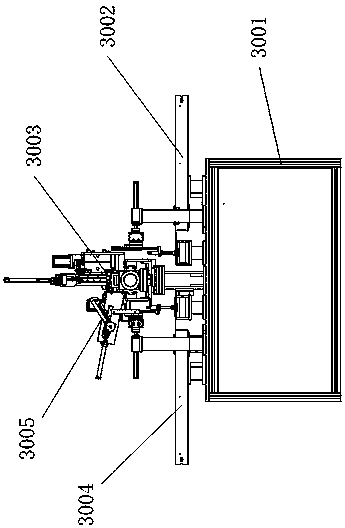

[0031] Such as figure 1The shown fully automatic resin lens mold clamping and pouring system includes a tape mold clamping machine for clamping the resin lens mold, a belt mold clamping machine for transporting the mold clamped lens mold to the resin lens casting machine Automatic mold feeding device for lens molds, resin lens pouring machine for automatic pouring of resin lenses, automatic lens mold taking device for placing casted lens molds in mold trays.

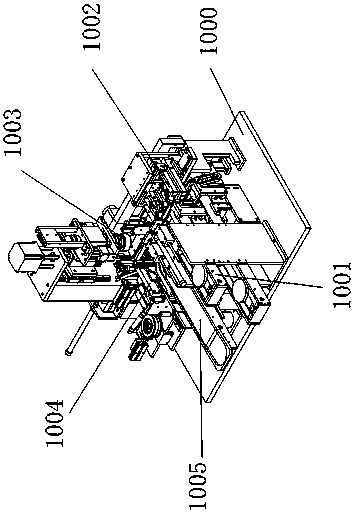

[0032] Such as figure 1 , figure 2 As shown, the adhesive tape mold clamping machine includes a frame one 1000 and a conveying and positioning device 1001, a center-parallel clamping device 1002, a main body detection mold clamping device 1003, an adhesive tape device 1004, a finished product ejecting device 1005, and a conveying and positioning device 1001 arranged in sequence. For transporting the lens mold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com