Integrative forming device of inspection machine for printing and folder-gluer

A forming device, folder-gluer technology, applied in the direction of packaging, transportation and packaging, container manufacturing machinery, etc., can solve the problems of uncontrollable falling position and angle, uneven paper weight and friction, and irregular paper arrangement, etc. Achieve the effects of reducing labor costs, smooth motion trajectory, and facilitating lamination and arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

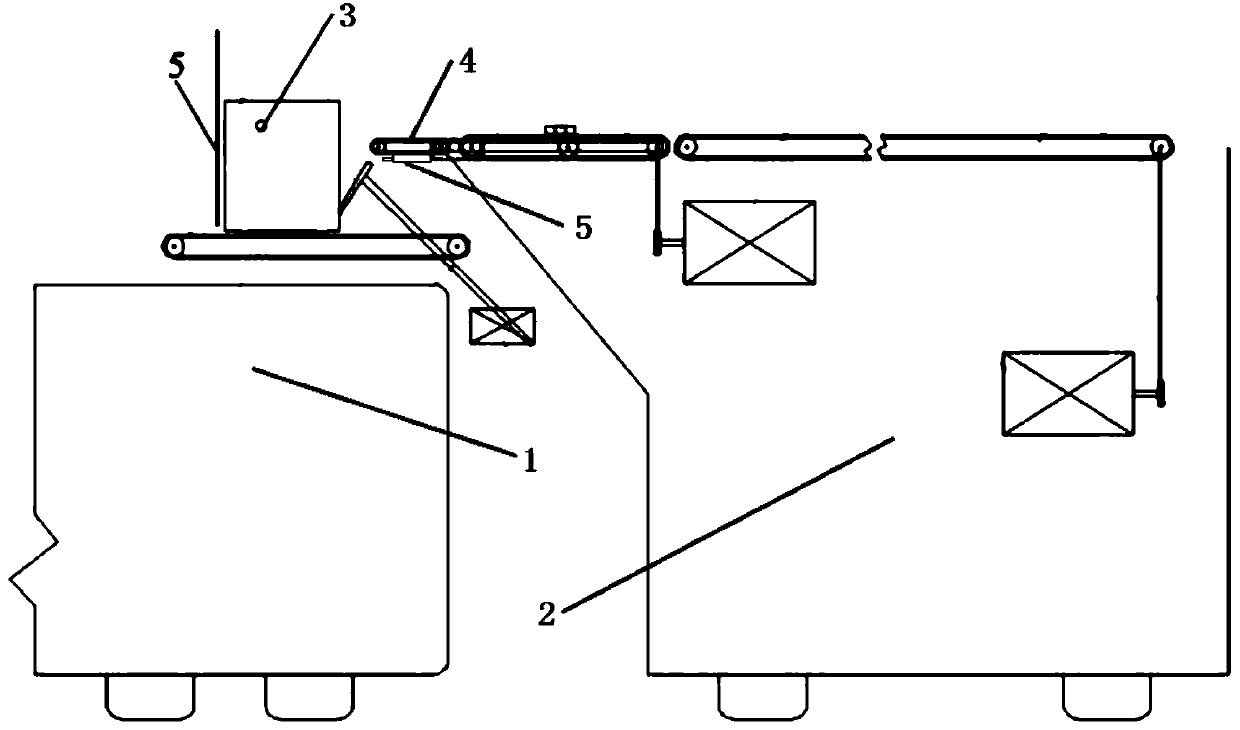

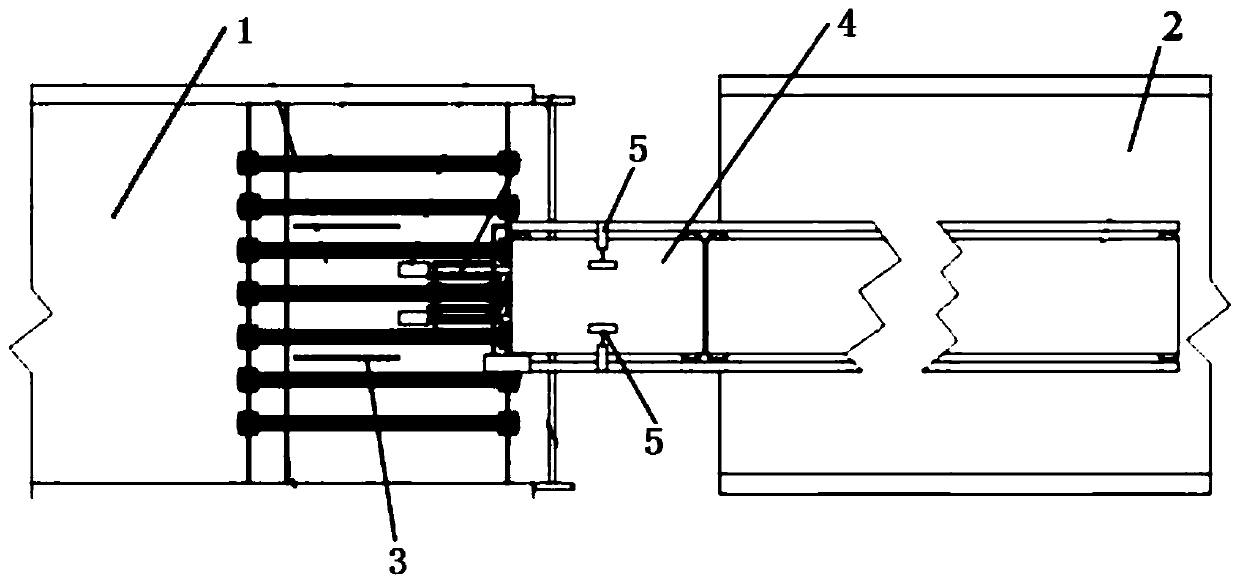

[0028] An integrated forming device of a printing inspection machine and a folder-gluer, comprising: a folder-gluer 1 and an inspection machine 2; it is characterized in that a feed chute 3 is provided at the input end of the folder-gluer, and the inspection The output end of the machine is provided with a conveyor belt 4; the feed chute 3 is docked with the conveyor belt 4, the upper mouth of the feed chute 3 is located at the front end of the conveyor belt 4, and the upper mouth of the feed chute 3 has a lower level On the conveyor belt 4; the bottom of the conveyor belt 4 is provided with an air spray device 5.

Embodiment 2

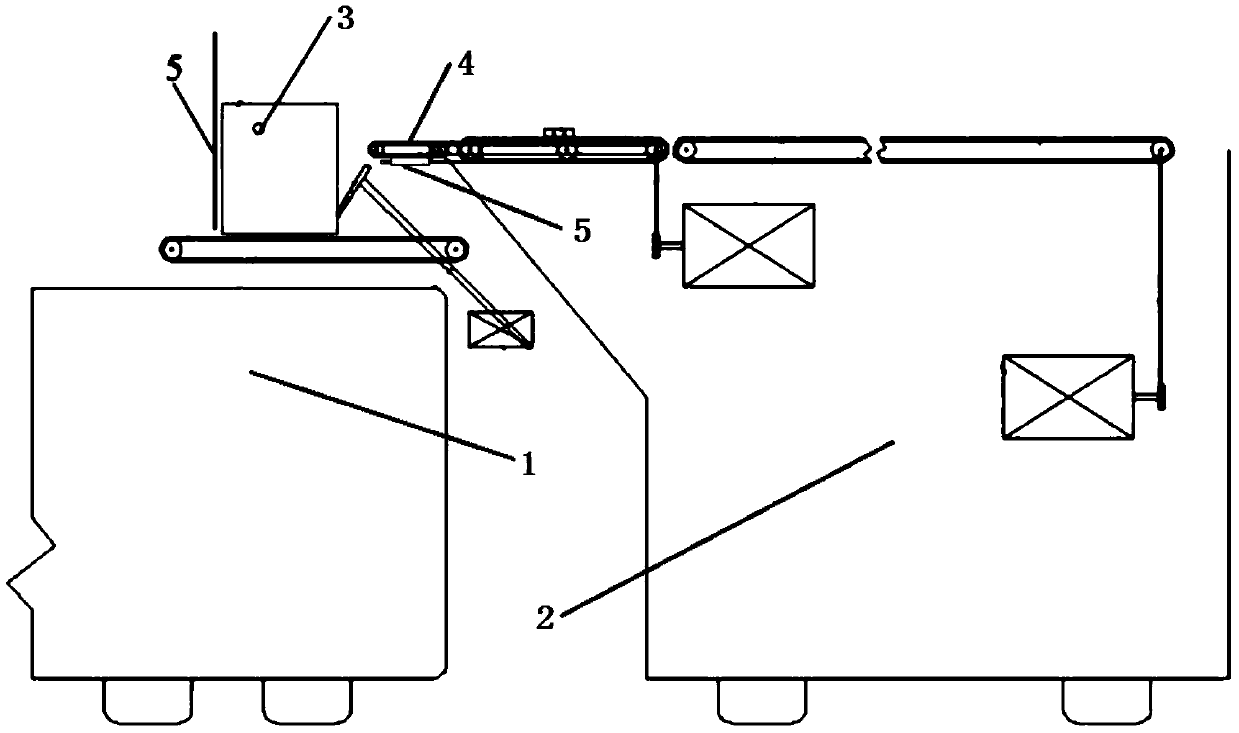

[0030] An integrated forming device of a printing inspection machine and a folder-gluer, comprising: a folder-gluer 1 and an inspection machine 2; it is characterized in that a feed chute 3 is provided at the input end of the folder-gluer, and the inspection The output end of the machine is provided with a conveyor belt 4; the feed chute 3 is docked with the conveyor belt 4, the upper mouth of the feed chute 3 is located at the front end of the conveyor belt 4, and the upper mouth of the feed chute 3 has a lower level On the conveyor belt 4; the bottom of the conveyor belt 4 is provided with an air spray device 5.

[0031] The front end of the feed chute is provided with a baffle for ordering the products.

Embodiment 3

[0033] An integrated forming device of a printing inspection machine and a folder-gluer, comprising: a folder-gluer 1 and an inspection machine 2; it is characterized in that a feed chute 3 is provided at the input end of the folder-gluer, and the inspection The output end of the machine is provided with a conveyor belt 4; the feed chute 3 is docked with the conveyor belt 4, the upper mouth of the feed chute 3 is located at the front end of the conveyor belt 4, and the upper mouth of the feed chute 3 has a lower level On the conveyor belt 4; the bottom of the conveyor belt 4 is provided with an air spray device 5.

[0034] The minimum horizontal distance between the upper edge of the feeding trough and the front end of the air injection device is 12-15 cm. If the horizontal distance is too long, the paper cannot fall into the feeding chute accurately, or the volume of the feeding chute is too large, resulting in waste of cost. If the horizontal distance is too short, the pape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com