A Casting Process of Rear Axle Hub Connector

A rear axle wheel hub and casting process technology, which is applied in the field of auto parts, can solve the problems of the use and waste of the shaft cavity space, achieve the effects of improving quality, ensuring the overall strength requirements, and improving the use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

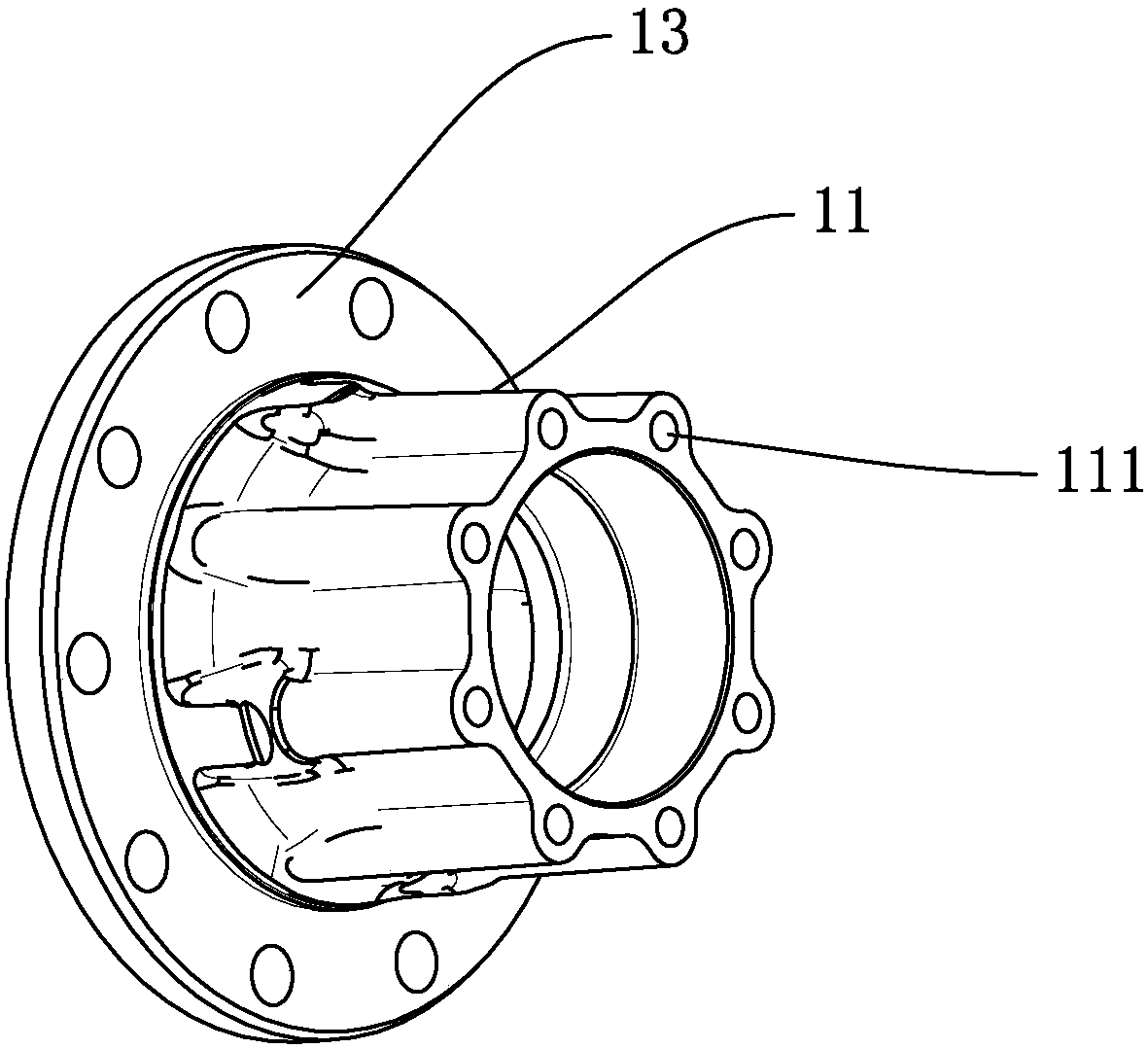

[0047] Embodiment 1, a rear axle hub connector, see attached Figure 1-3 , including a cylindrical body, on which a connecting disc 13 is arranged to divide the cylindrical body into two sections, wherein the longer section is a splined cylinder 11 with a flower-shaped cross-section, and the shorter section is a positioning cylinder 12, The positioning cylinder 12 will cooperate with the brake drum (not shown in the figure) when in use, the positioning cylinder 12 will be inserted into the brake drum, and the end of the brake drum opposite to the connecting disc 13 is provided with a bolt, and the bolt will pass through After the connecting hole 131, the wheel is loaded on the brake drum. The wheel is provided with a mounting hole for passing through the bolt. After the mounting hole of the wheel passes through the bolt, the wheel is fixed by a nut.

[0048] See attached figure 1 , the end of the spline barrel 11 is provided with a threaded hole or a bolt hole 111 around its ...

Embodiment 2

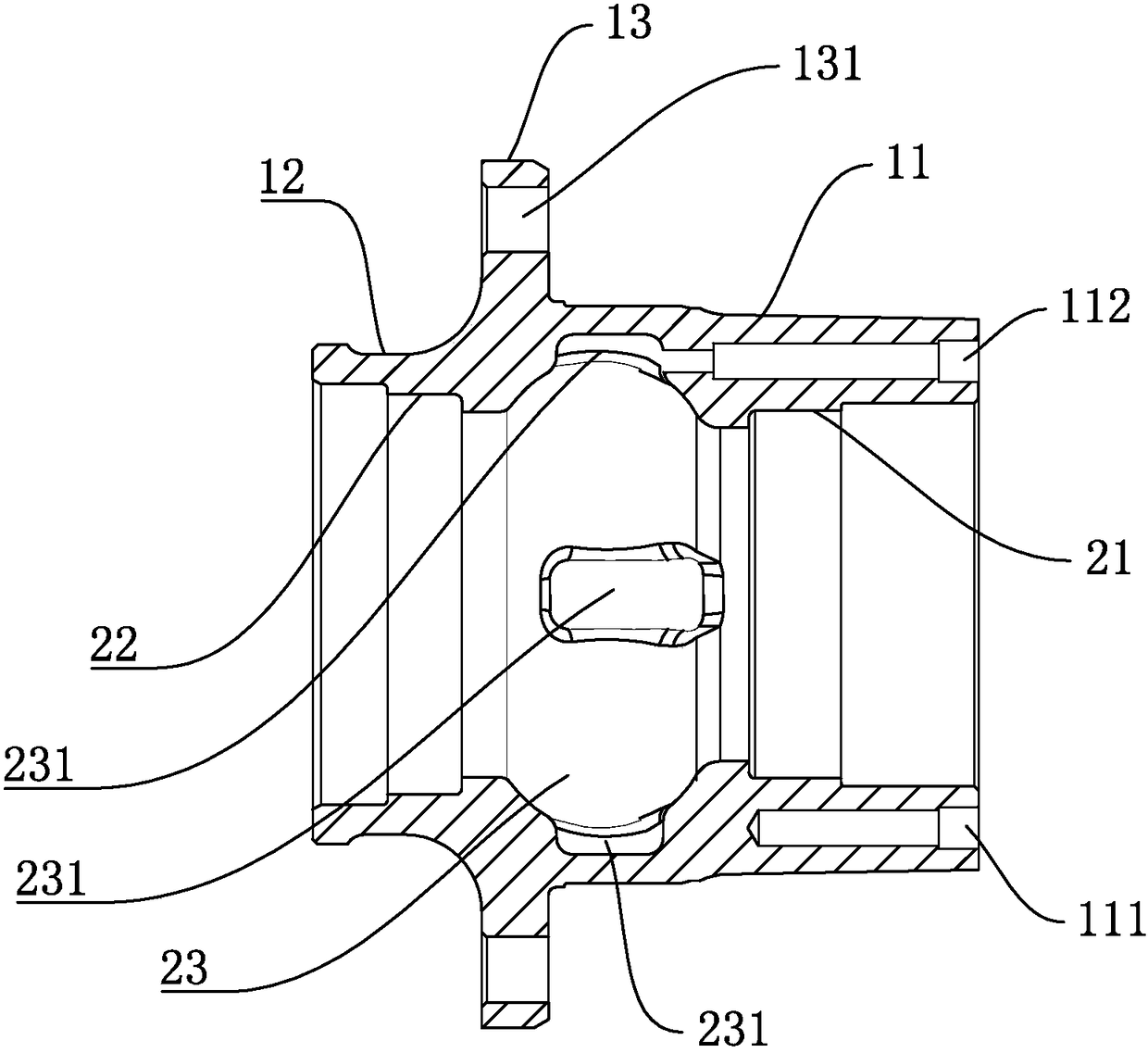

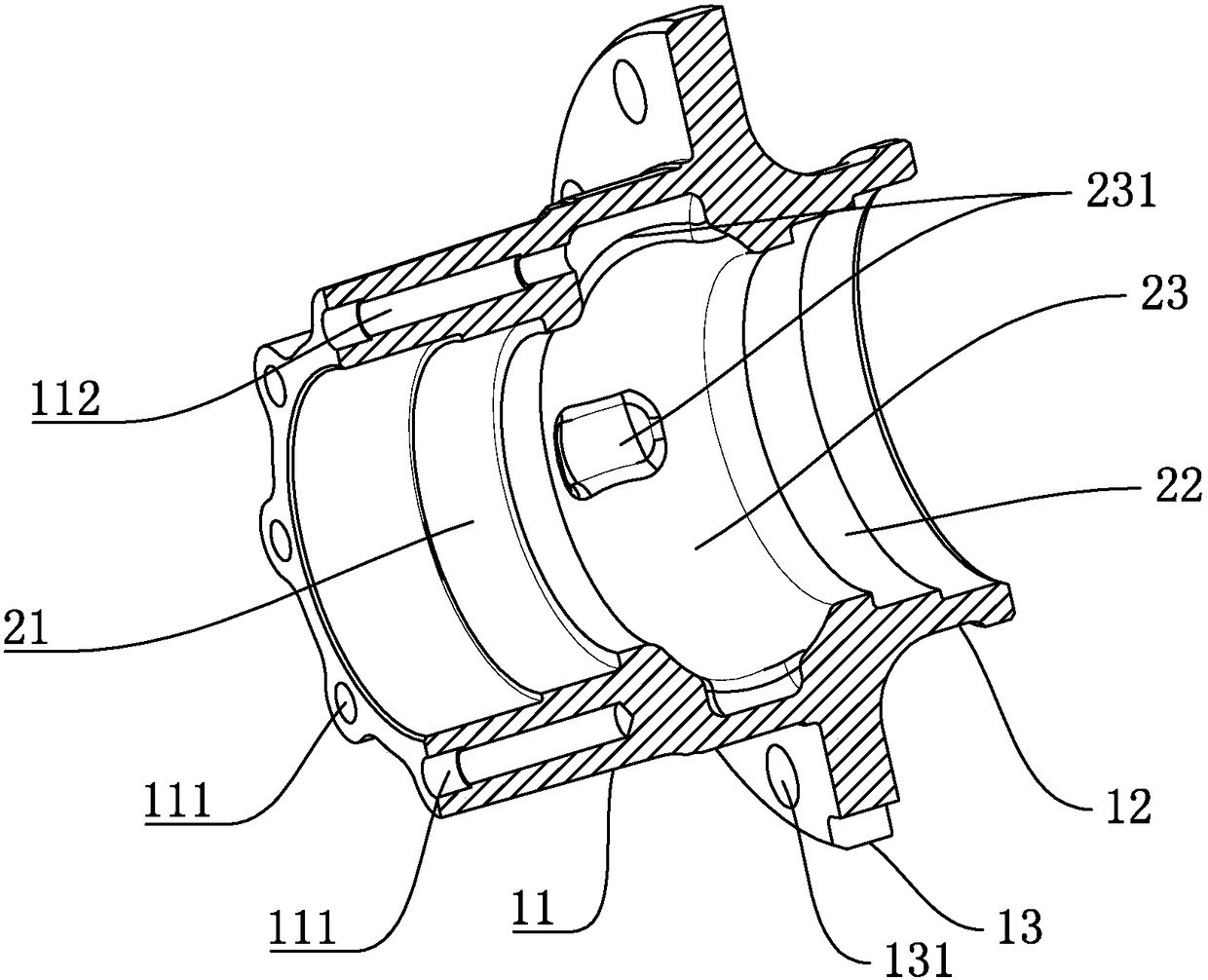

[0052] Embodiment 2, a production mold of a rear axle hub connector, see attached Figure 4 with 5 , since this rear axle hub connector of the present invention has an axial hole, and the axial hole includes an inner bearing cup 21, an outer bearing cup 22 and a shaft cavity 23, the inner cavity structure of the rear axle hub connector is complicated, and the general Casting with internal core-pulling moulds will not only increase the cost of the mould, but it is also difficult to control the stability of the cast product, which is prone to problems such as structural strength or internal stress concentration of the product, and the mold is very easy to damage and difficult to repair; Therefore, in order to adapt to the rear axle hub connector with a complex inner cavity structure, the sand core 3 that is consistent with the axial cavity wall shape of the rear axle hub connector is used for auxiliary casting, and the circumferential wall surface of the sand core 3 Consistent ...

Embodiment 3

[0055] Embodiment 3, a production process of a rear axle hub connector, using the mold in Embodiment 2, casting with a sand core 3 casting process, the steps include the following:

[0056] S1. Preheating, raise the mold temperature to 410±20°C and then spray heat-insulating paint, raise the temperature of sand core 3 to 200±20°C and then spray heat-insulating paint;

[0057] S2. Mold loading, put the mold into the differential pressure casting table (here, the pressure difference between the metal liquid surface of the holding furnace and the inside of the mold adopts the pressurization method, and the gas of the same pressure is first introduced into the sealing cover and the holding furnace at the same time , so that the pressure between them is balanced, and then maintain the gas pressure value in the sealed cover, gradually introduce a higher pressure gas to the metal liquid surface in the holding furnace, and create a pressure difference between the upper and lower tanks,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com