High-precision camera shooting measuring method for detecting sedimentation and pose of railway detecting vehicle

A technology for camera measurement and detection of vehicles, which is applied in the direction of railway vehicle shape measuring devices, railway car body parts, railway auxiliary equipment, etc., which can solve the problems of high measurement cost, heavy workload, and high maintenance cost of facilities, and achieve high measurement accuracy, fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

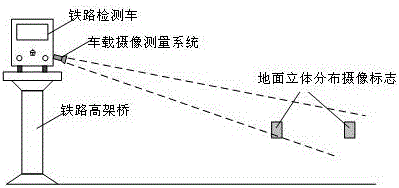

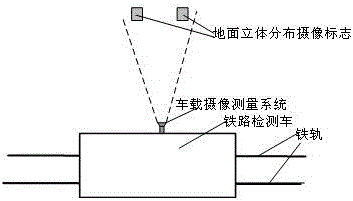

[0023] (1) Photogrammetry based on three-dimensional distribution marks

[0024] On the ground outside the railway, a plurality of camera measurement marks distributed in space are arranged. The relative relationship between the camera marks is known. By analyzing the imaging relationship between the marks on the image, the settlement and attitude parameters of the detection vehicle can be measured separately.

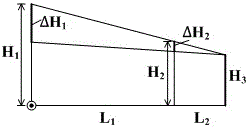

[0025] 1) Subsidence camera measurement based on three-dimensional distribution marks

[0026] Due to the shaking of the detection vehicle platform during dynamic measurement, the pointing and attitude of the vehicle-mounted camera measurement system will change, the three-dimensional distribution marks must be reasonably designed to measure the settlement of the detection vehicle, so that the measurement is basically not affected by the camera attitude, that is, the direction of the optical axis. The invention utilizes the characteristic that the relative relation of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com