Winding machine for the manufacture of lap spools and method for winding a lap

A technology of winding machine and lap, which is applied in the field of winding lap, can solve the problems of expensive structure and cost, and achieve the effect of lowering temperature level, reducing fuzziness, and avoiding sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

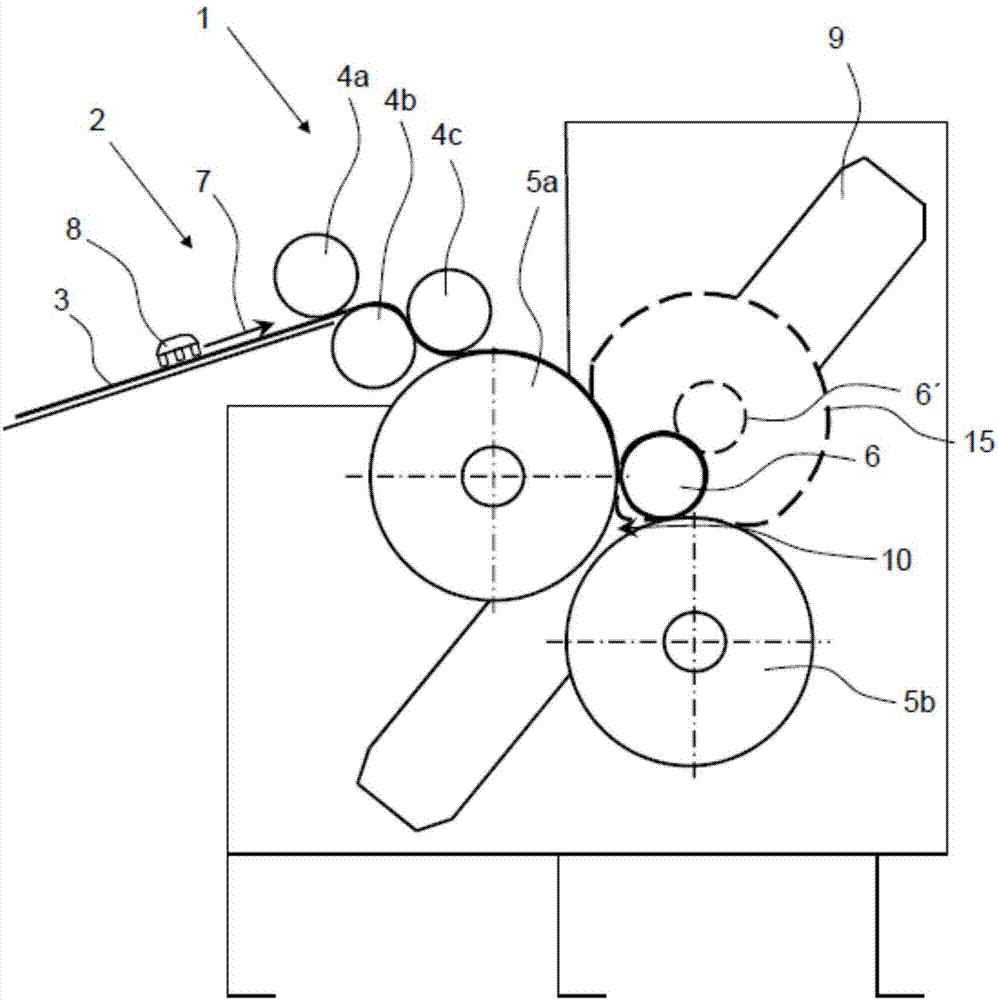

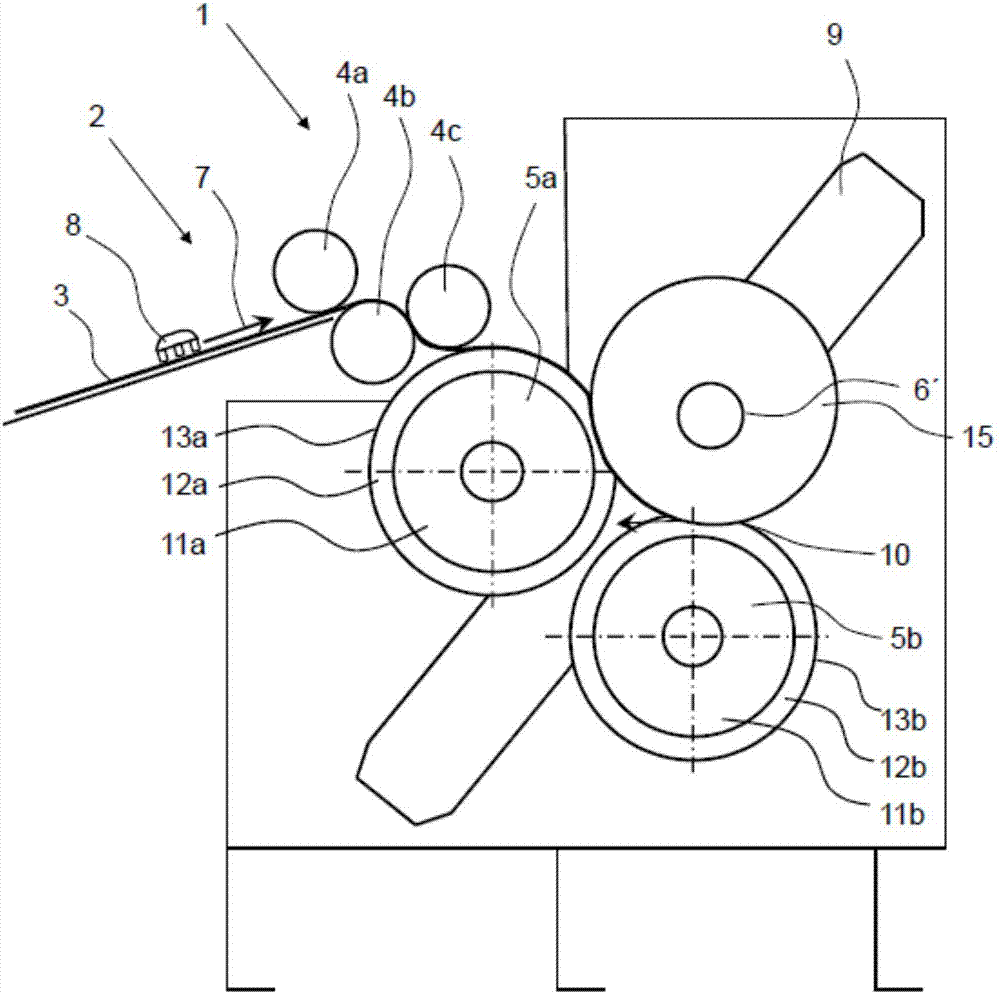

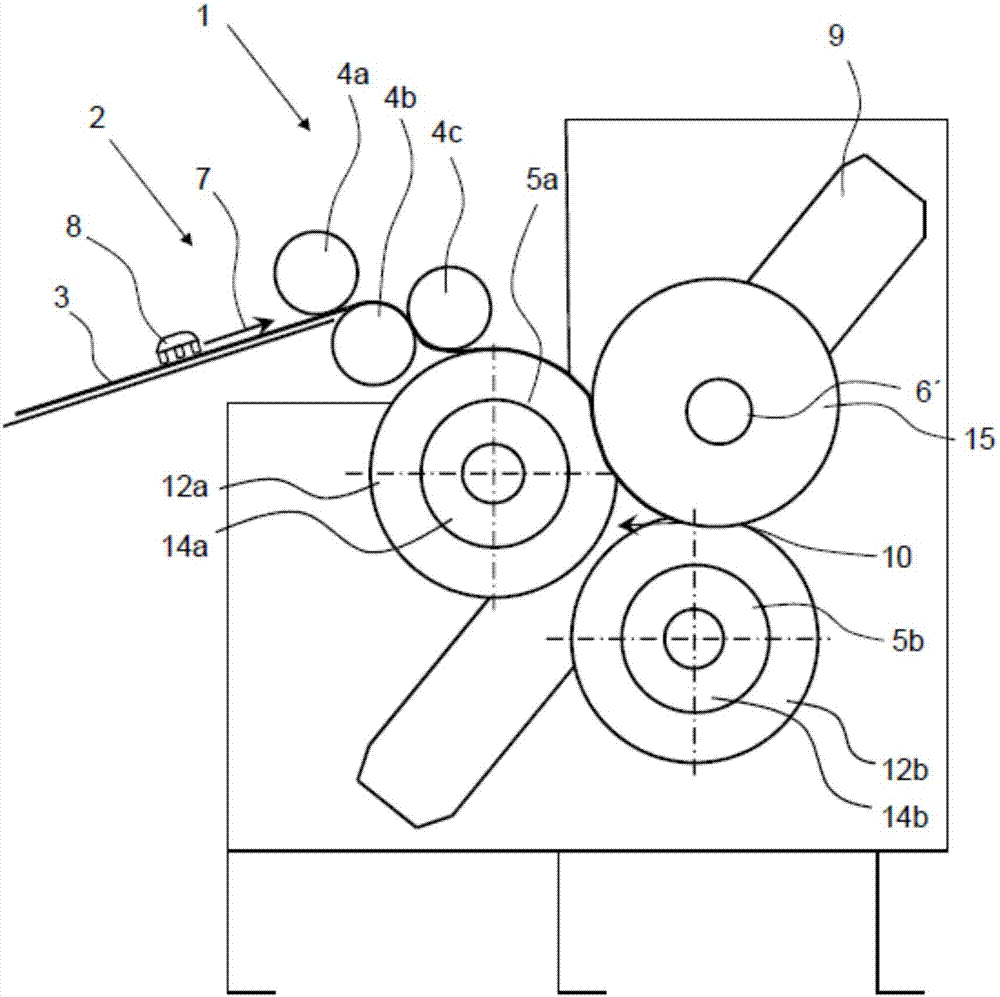

[0028] exist figure 1 The winder 1 is shown in the textile industry for example in the preparation of a combing shop How to use it according to the existing technology. A plurality of fiber ribbons 3 , which may be made of natural or man-made fibers, are conveyed through the cans of the winder 1 and stretched in a drafting device not shown. The fiber web 3 is guided further along the material flow direction 7 through the feed area 2 to a plurality of pressure rollers 4 a - 4 c which guide the fiber web 3 between the two winding rollers 5 a , 5 b and the winding sleeve 6 . Between the pull-in area for the production of cotton lap reels (Wattwickel). A precompressor 8 , which homogenizes the fiber strip 3 , can be arranged in or on the feed region 2 . Alternatively, the lap reel can also be produced between one or two winding rollers and a surrounding belt.

[0029] The winding sleeve 6 is clamped on its end side by two not shown side disks and runs along the guide rail 9 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com