Eco-friendly method for prefabricated concrete trough type sheet pile

A technology of prefabricated concrete and ecological environment, applied in the field of foundation piles, can solve the problems of large differences in soil living environment and the impact of living environment of aquatic animals and plants, and achieve the effect of simple construction, not easy to damage, and high economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention and the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings. The described embodiments are only some of the embodiments of the patent of the present invention, not all of them.

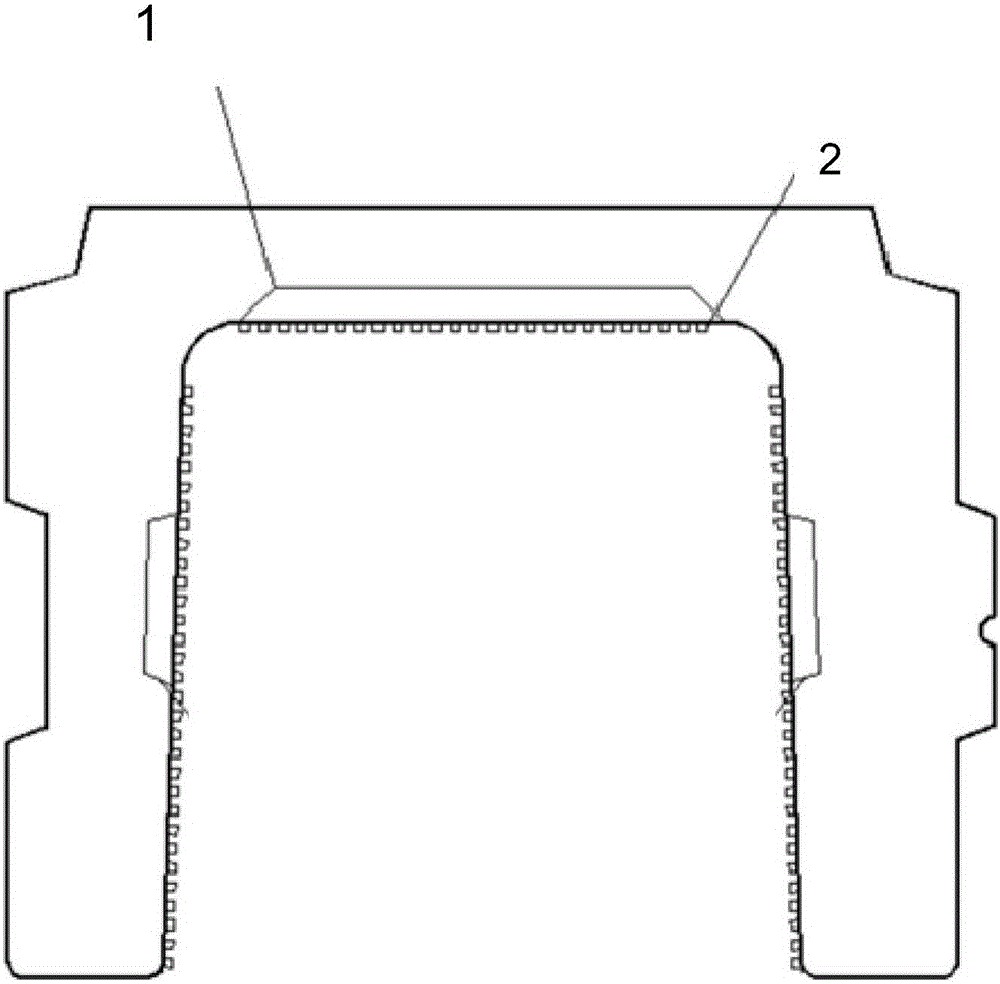

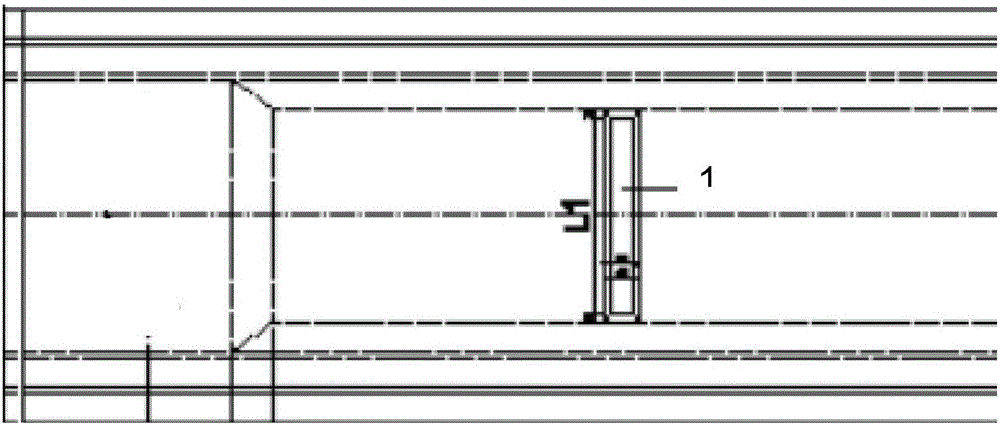

[0014] An eco-friendly method for prefabricated concrete grooved sheet piles described in the present invention includes a pile body made of reinforced concrete, the cross section of the pile body is grooved, and the material of the prefabricated concrete grooved sheet piles is weakly alkaline or destructive Cement is used as the base material to reduce the alkalinity of sheet piles; biological nesting holes are set on the sheet pile body, and bionic textures are set on the pile body facing the water. The biological nesting holes and bionic textures provide aquatic animals and plants with a similar environment living environment;

[0015] Such as figure 1 , 2 As show...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap