Boss sealing structure for comprehensive pipe rack

A technology of sealing structure and comprehensive pipe gallery, applied in underwater structures, infrastructure engineering, water conservancy engineering and other directions, can solve problems such as easy damage of water stop and difficult replacement, achieve convenient use, ensure sealing effect, and improve use effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

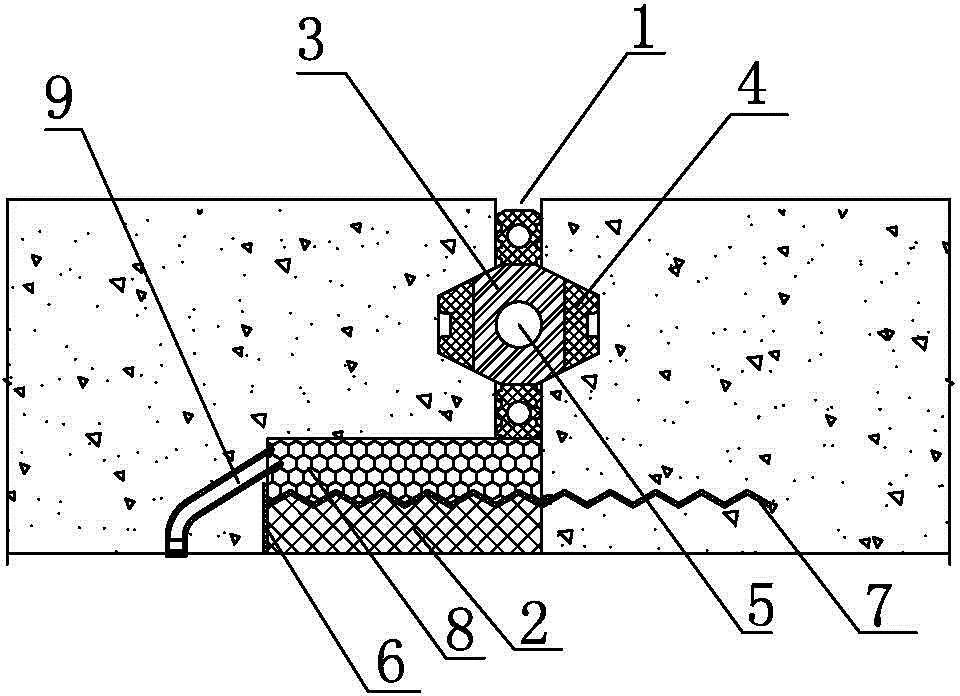

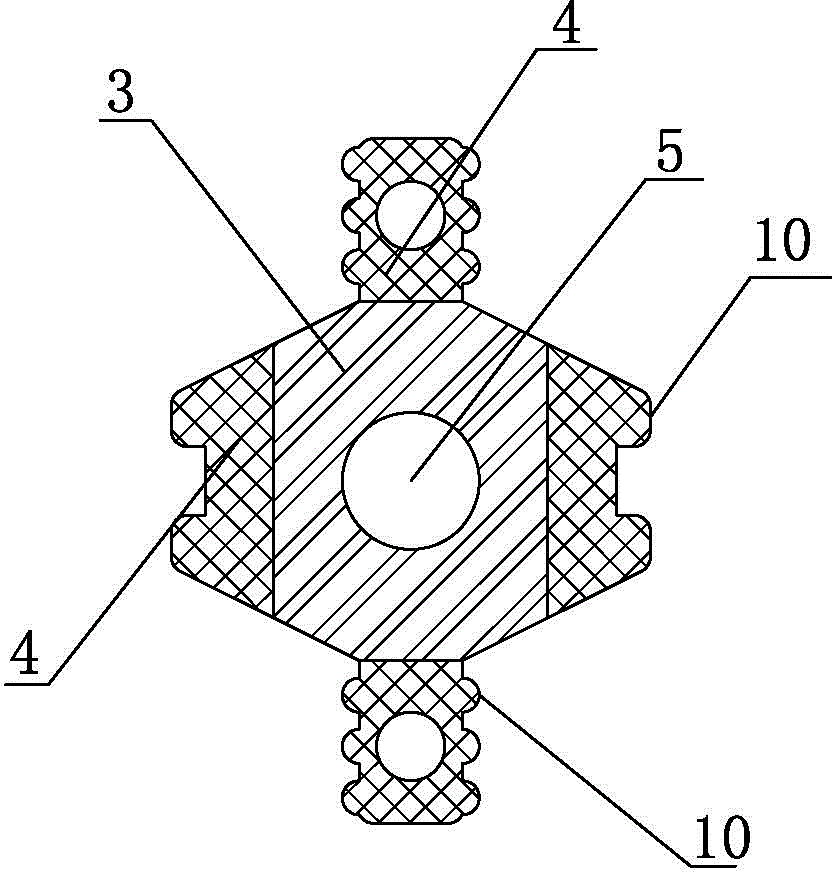

[0015] Embodiment 1: A sealing structure of a boss 10 of a comprehensive pipe gallery, which is arranged at the junction of two adjacent pipe galleries. The structure includes a gap, a seal and a sealing groove 2, and the gap is arranged on the end faces of both ends of the pipe gallery. The sealing groove 2 is arranged at one end of the pipe gallery, and is located below the gap on the end face; after the two adjacent sections of the pipe gallery are connected, the two opposite gaps form a groove 1, and the seal is placed in the groove 1; the seal Including shrinkable rubber 3 and water-swellable rubber 4, shrinkable rubber 3 is rectangular, with holes 5 inside, water-swellable rubber 4 is arranged on the upper, lower, left and right surfaces of shrinkable rubber 3; Fill with concrete. A pre-embedded plate 6 is provided on the vertical inner wall of the sealing groove 2 provided at one end of the pipe gallery, and a metal water-stop strip 7 is pre-embedded at the other end. ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap