Integrated house wall structure

An integrated house and wall structure technology, applied in the field of integrated house wall structure, can solve the problems of poor wind and moisture proof effect, and achieve good thermal insulation effect, good enclosure effect, and good wind and moisture proof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

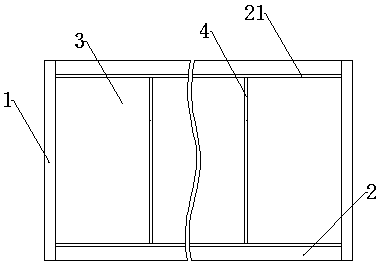

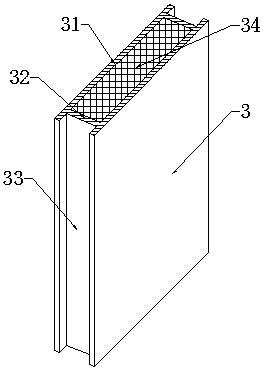

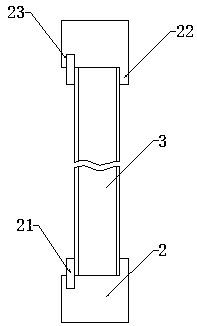

[0026] Embodiment 1, this embodiment is basically as attached figure 1 Shown: the wall structure of an integrated house, including columns 1, beams and rectangular plate-shaped walls; such as image 3 As shown, the crossbeam includes a crossbeam body 2, and a positioning platform 22 is integrally formed on the crossbeam body 2, and a positioning groove 23 is provided on the crossbeam body 2 on one side of the positioning platform 22, and a limit bar 21 is provided in the positioning groove 23, and the bottom of the wall The end is clamped and clamped between the two by the positioning table 22 and the limit bar 21, and the side end of the wall is detachably connected to the column 1. Such as figure 2 As shown, the wall includes several rectangular wall panels 3 with a length of 2000 mm and a width of 600 mm. The wall panels 3 include a frame and a thermal insulation layer 34; The oppositely arranged panel 31 and two side panels 32 between the two panels 31, the opposite sid...

Embodiment 2

[0028] Embodiment two, the difference between this embodiment and embodiment one is only that the size of wallboard 3 is long 2000 millimeters, the rectangular plate of wide 300 millimeters, and panel 31 is flat rectangular plate, as Figure 5 As shown, the side plate 32 is a special-shaped plate with a U-shaped cross section, and the panel 31 and the side plate 32 are connected and fixed by welding (welding is the preferred method used in this embodiment, and press-fitting, clipping, and bolting can also be used. , bonding, etc.). The size of the wall panel 3 set in this way can be applied to most transport vehicles, and is more convenient for handling; it is also more flexible in use, and when a small part needs to be replaced, only a small area needs to be replaced, which is more convenient. The contact area between the U-shaped side plate 32 and the panel 31 is larger, which can provide stronger support for the panel 31, and the formed wall panel 3 has better bending resis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com