Aluminum alloy pipe concrete composite column with internal restraining plate

An aluminum alloy tube and restraint plate technology, which is applied to columns, piers, pillars, etc., can solve the problems of multiple welding processes, heavy steel pipes, and difficulty in realization, and achieves reduced structural weight, maintenance-free costs, and good corrosion resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

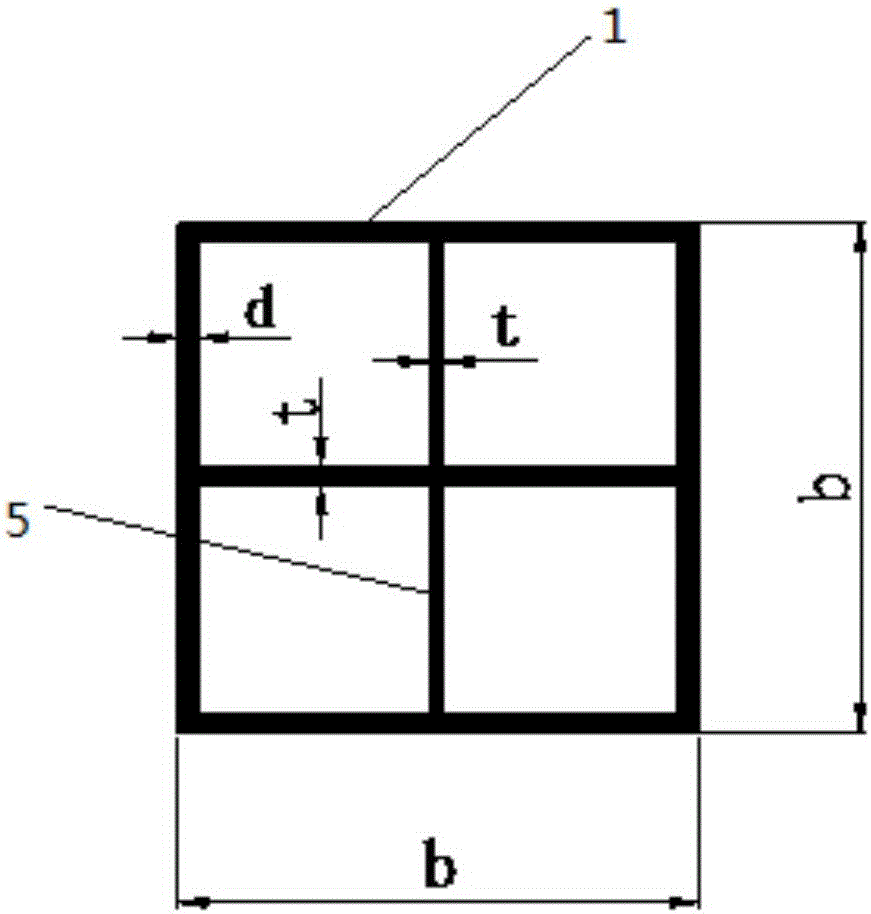

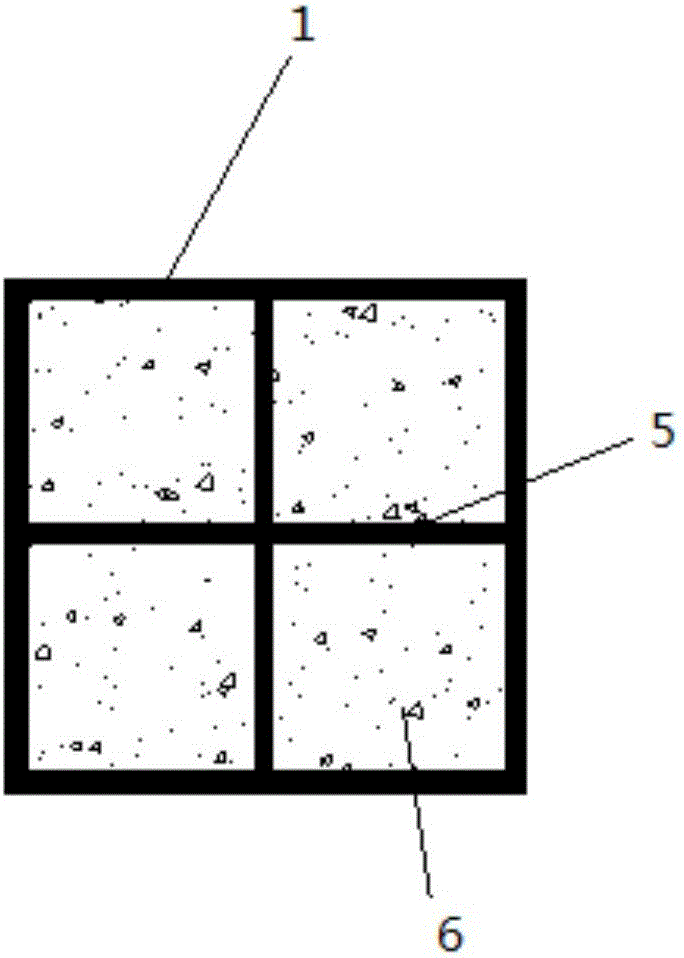

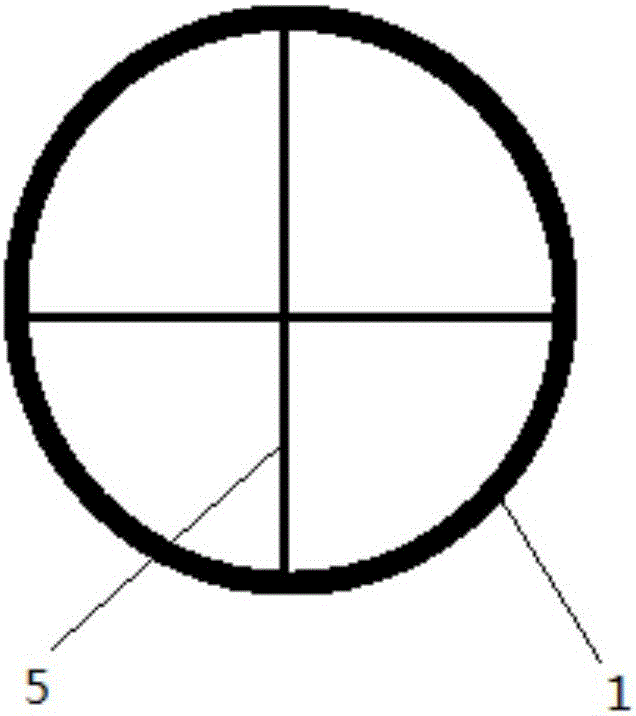

[0065] Such as figure 1 Shown, adopt the composite column of the present invention to build the frame composite structure house. The floor height is 3.6 meters, using square composite columns, alloy aluminum tubes using 6 series high-strength aluminum alloys, material conditional yield strength 240MPa, elastic modulus 70GPa, and concrete using C40 strength grade. The specific implementation steps are as follows:

[0066] 1. According to the depth and bay of the house, the size b of the square aluminum alloy column tube is initially determined;

[0067] 2. Calculate the structural design load and the most unfavorable internal force combination value according to the relevant load design specifications;

[0068] 3. Determine the wall thickness d of the square aluminum alloy tube and the thickness t of the inner cross-shaped restraint plate according to the design load;

[0069] 4. According to the designed aluminum alloy tube section, process it in the factory to make aluminu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com