Grout dry building method for high-precision building blocks

A block and dry laying technology, applied in the field of block masonry, can solve problems such as unfavorable building quality, hollow walls, cracks, etc., to improve production efficiency and masonry quality, reduce wall cracks, and improve wall The effect of precision and look and feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

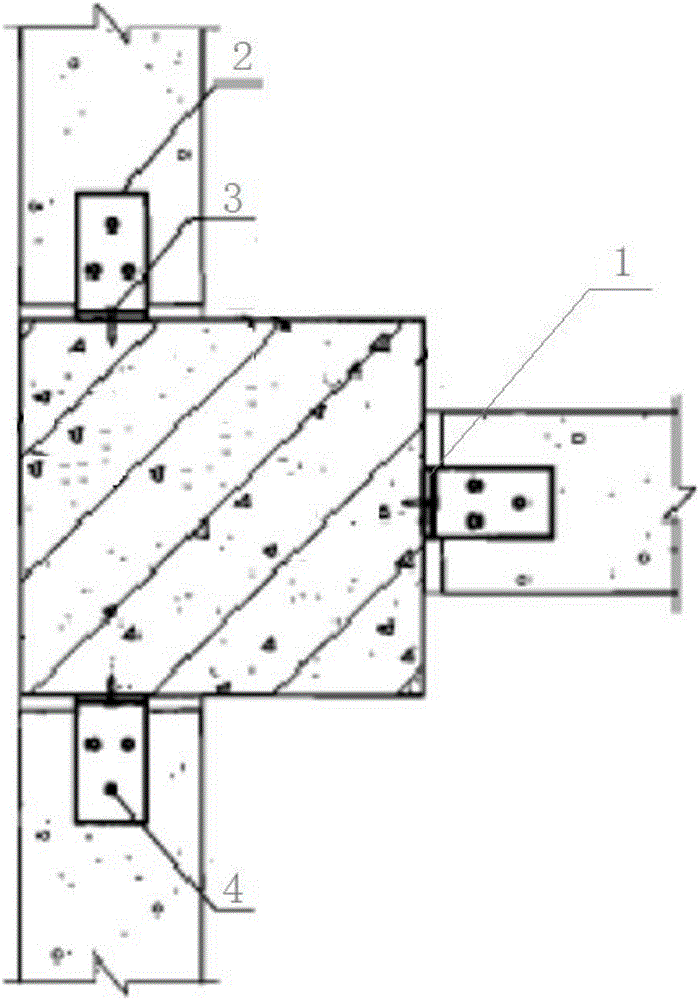

[0020] see figure 1 , a method for dry-laying high-precision block grout, the specific steps are as follows:

[0021] 1) High-precision blocks are used to control the precision of the masonry. The allowable deviation of the size of the high-precision blocks is: length -2~0mm, width -1~1mm, height -1~1mm;

[0022] 2) Use a special adhesive with good workability, water retention, and fluidity for dry construction masonry. Before masonry, it is not necessary to spray water on the high-precision blocks, and strictly control the age of the upper wall to 28 More than 10 days, the moisture content is less than 15%;

[0023] 3) Arrange the blocks in advance before masonry, from top to bottom, and reserve a 20mm top joint at the top to replace the inclined roof brick masonry of the traditional masonry process, and the thickness of the mortar joint is controlled at 3mm;

[0024] 4) 14 days after the masonry is completed, use expansive cement mortar to grout the reserved top joints;

...

Embodiment 2

[0028] see figure 1 , a method for dry-laying high-precision block grout, the specific steps are as follows:

[0029] 1) High-precision blocks are used to control the precision of the masonry. The allowable deviation of the size of the high-precision blocks is: length -2~0mm, width -1~1mm, height -1~1mm;

[0030] 2) Use a special adhesive with good workability, water retention, and fluidity for dry construction masonry. Before masonry, it is not necessary to spray water on the high-precision blocks, and strictly control the age of the upper wall to 28 More than 10 days, the moisture content is less than 15%;

[0031] 3) Arrange blocks in advance before masonry, from top to bottom, and reserve a 25mm top joint at the top to replace the inclined roof brick masonry of the traditional masonry process, and the thickness of the mortar joint is controlled at 4mm;

[0032] 4) 16 days after the masonry is completed, use expansive cement mortar to grout the reserved top joints;

[00...

Embodiment 3

[0036] see figure 1 , a method for dry-laying high-precision block grout, the specific steps are as follows:

[0037] 1) High-precision blocks are used to control the precision of the masonry. The allowable deviation of the size of the high-precision blocks is: length -2~0mm, width -1~1mm, height -1~1mm;

[0038] 2) Use a special adhesive with good workability, water retention, and fluidity for dry construction masonry. Before masonry, it is not necessary to spray water on the high-precision blocks, and strictly control the age of the upper wall to 28 More than 10 days, the moisture content is less than 15%;

[0039] 3) Arrange the blocks in advance before masonry, from top to bottom, and reserve a 30mm top joint at the top to replace the inclined roof brick masonry of the traditional masonry process, and the thickness of the mortar joint is controlled at 5mm;

[0040] 4) 18 days after the masonry is completed, use expansive cement mortar to grout the reserved top joints;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com