Large-scale two-stroke turbocharging compression ignition internal combustion engine having waste gas cleaning system

A technology for internal combustion engines and turbocharging, applied to internal combustion piston engines, combustion engines, engine components, etc., can solve problems such as low NOx, low exhaust gas temperature, and conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In the following detailed description of a large crosshead turbocharged two-stroke diesel engine and a method for operating a large crosshead turbocharged two-stroke diesel engine according to the invention will be described by way of example embodiments.

[0047] The construction and operation of large turbocharged crosshead two-stroke compression ignition internal combustion engines are well known and will not require further explanation in this text. Additional details regarding the operation of the exhaust gas cleaning system are provided below.

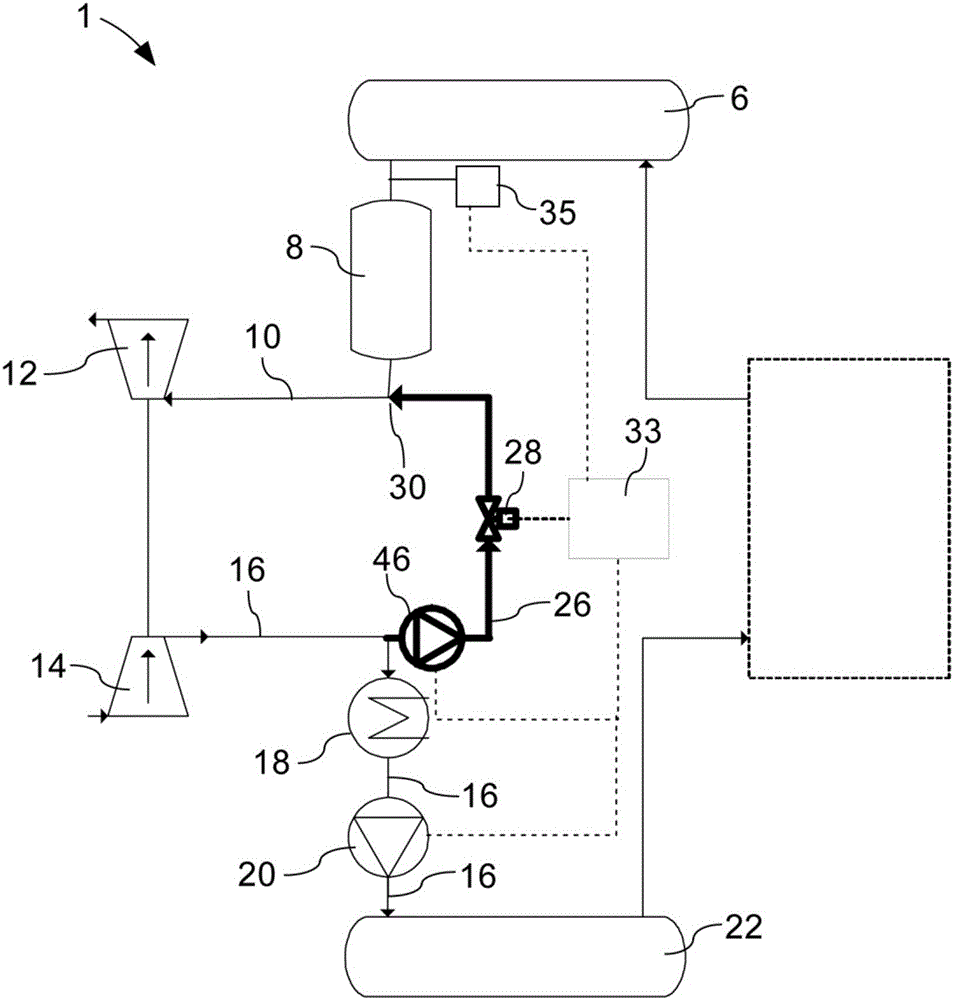

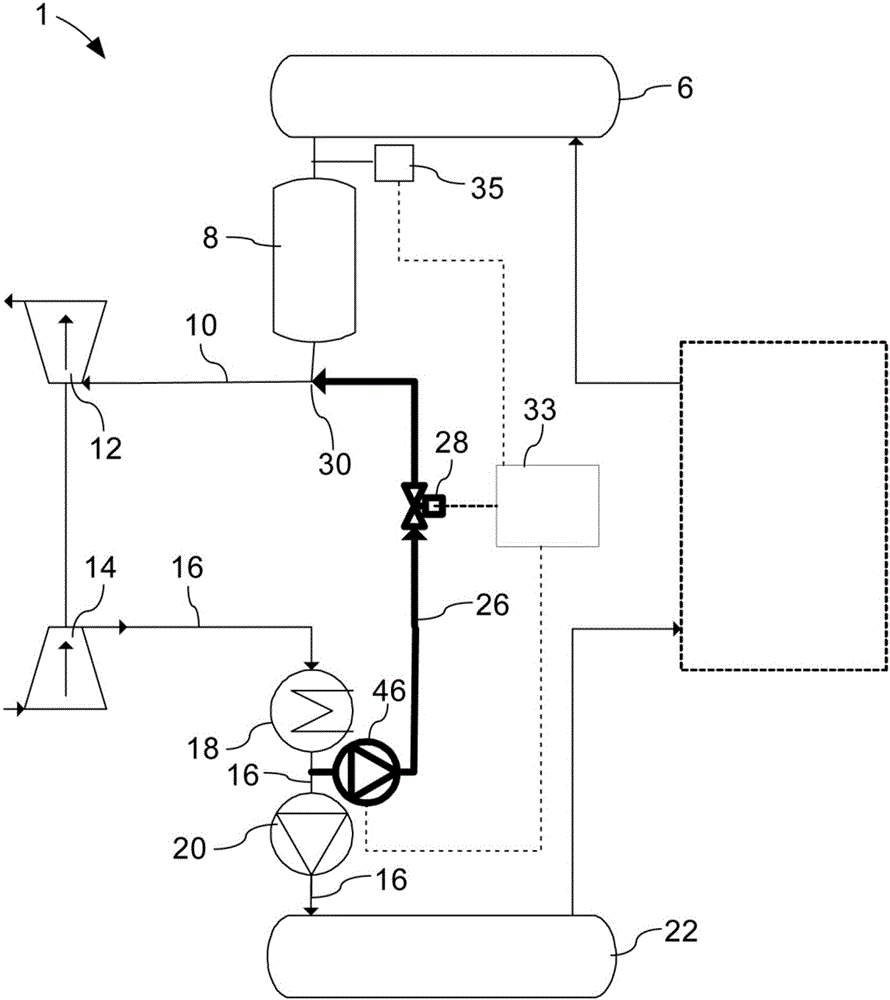

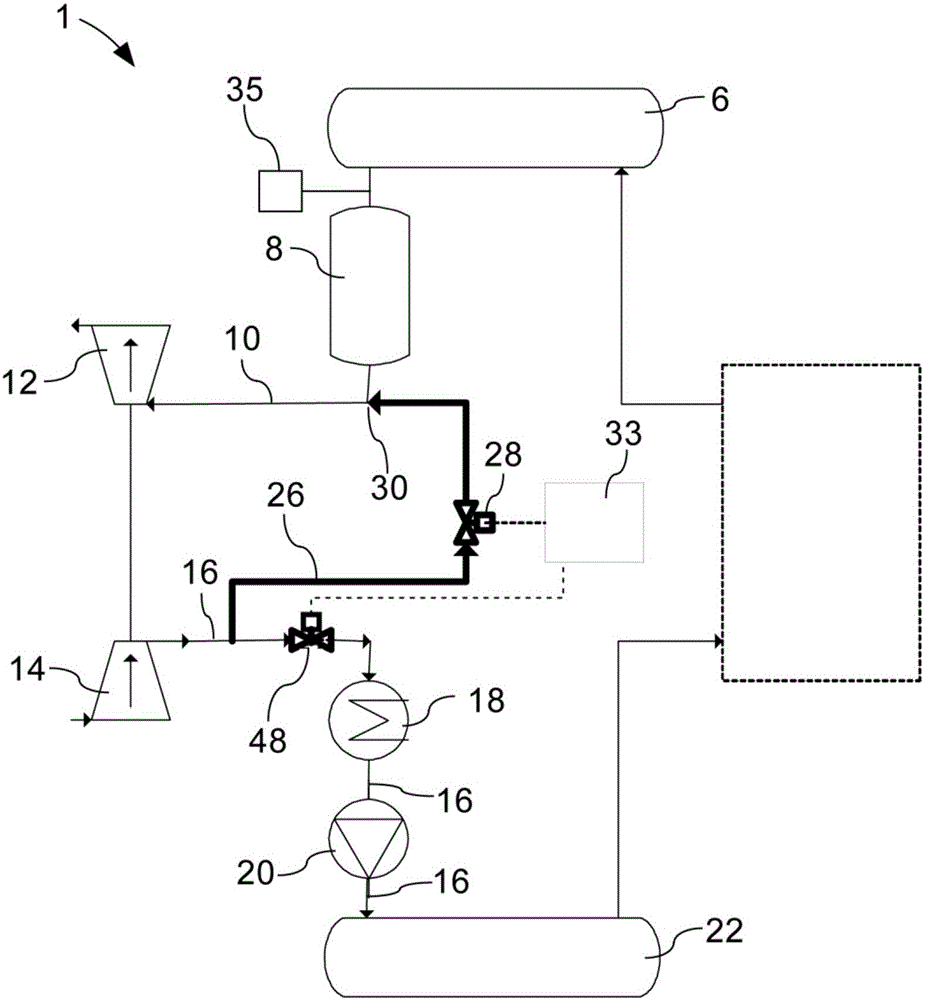

[0048] figure 1 A schematic depiction of a first example embodiment of a large two-stroke compression-ignition internal combustion engine 1 according to the invention is shown. The engine may, for example, be used as the main engine in an ocean-going vessel or as a stationary engine for operating a generator in a power station. For example, the total output of the engine may range from 5,000 kW to 110,000 kW.

[0049] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com